A new kind of horizontal well has emerged from an experiment in North Dakota’s Bakken and Three Forks shales.

It uses an uncemented slotted liner to produce hydrocarbons by intercepting fractures that originate from offset wells.

Hess Corp. revealed the concept over 2 years ago, confirming at an SPE conference that crude was flowing from the pilot well. The New York City-headquartered oil company also announced that additional trials were in progress, though it withheld specific production figures.

The wait for those key details is now over.

At the recent Unconventional Resources Technology Conference (URTeC) in Houston, Hess presented its first technical paper on the augmented drainage development (ADD) pilots which it claims have proven the approach to be, at the very least, a technical success.

In URTeC 4044110, the company’s authors underlined their optimism in noting that ADD wells “could lead to a step change in productivity and recovery in unconventional developments.”

Hess acknowledges that economic and technical hurdles currently stand in the way of that vision.

But the upbeat assessment is backed by impressive production data from its inaugural pilot launched in 2021.

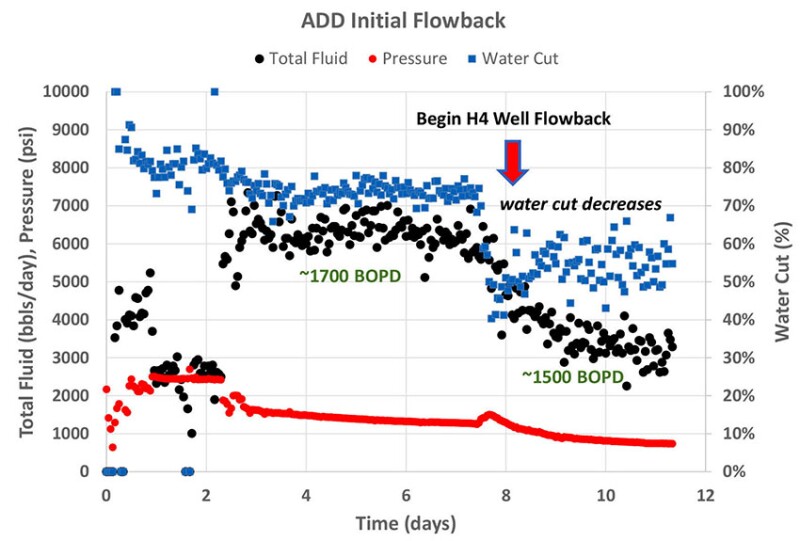

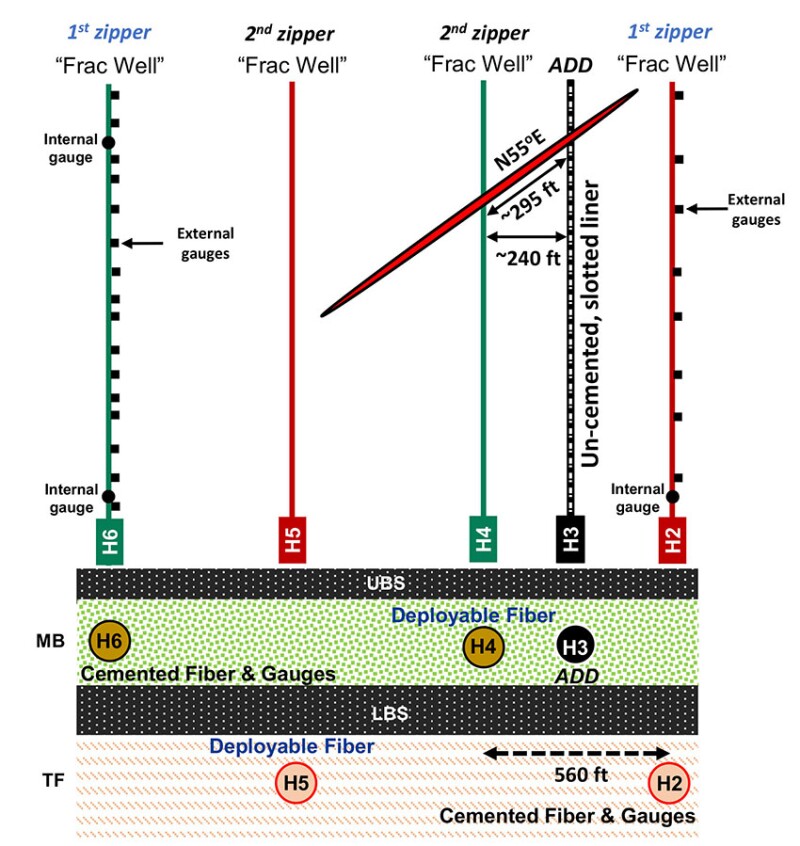

Placed about 240 ft between two actively stimulated Middle Bakken wells, the first drainage well exceeded expectations, averaging nearly 1,700 B/D of crude in the first 8 days of flowback.

Output fell to about 1,500 B/D over the next few days as the nearest actively stimulated well—called a “standard well” by Hess—began its flowback. This was one of several confirmations that the wells were in direct communication.

“A lot of bets were lost on this well—maybe not by me, but by a lot of people,” remarked Craig Cipolla, a principle completions engineering advisor for Hess.

Cipolla presented the company’s findings at the conference this past summer. He said the ADD well also pumped out about as much frac sand as is seen in a typical shale well, which in addition to tracer data, verified that it was well propped.

During the initial production period, the first ADD well achieved about 85% of the output of the offsetting standard wells on the pad. Although this figure eventually dropped to just over 40% over the next 2 years, it was enough for Hess to consider the concept validated.

Based on the results from all three pilots, Hess estimates ADD wells in the Bakken can be expected to achieve 10 to 45% of the output of typical hydraulically fractured horizontal wells.

On the low end, the oil recovered from distant and low-conductivity fractures likely won’t justify drilling even a wellbore as barebones as the ADD concept calls for.

Conversely, if a drainage well produces too much oil it is a sign that well spacing is too tight and that it is overly competing for resources with more-expensive offsets. This is likely the story of why the first ADD well came on so strong.

Cipolla did not specify the ideal production metric for Hess, but he noted that the range observed during the pilots “suggests that maybe there’s a sweet spot” where ADD wells could consistently deliver long-term value.

According to the models, optimal pad productivity might be achieved with standard frac wells spaced 1,000 ft apart and large fracture treatments. In this scenario, fracture half-lengths of 600 ft would be sufficient to overlap with an ADD well placed in the middle but without excessively draining the same reservoir area.

The Hess authors said this potential likely represents the model’s best effort to balance fracture conductivity, treatment design, and well spacing.

All of this points to another pressing issue: whether an ADD well truly enhances a pad’s recovery factor or merely accelerates production.

Hess remains uncertain on this point as well.

The earliest models and history-matched reservoir simulations indicated that ADD wells are accelerators only and do not offer a recovery boost.

On the other hand, decline curve analysis and rate transient analysis performed by Hess suggest there is an opportunity for incremental recovery gains.

Cipolla mentioned that newer models, calibrated with its most accurate fracture conductivity data, have been developed to help settle the matter.

Catching Frac Hits

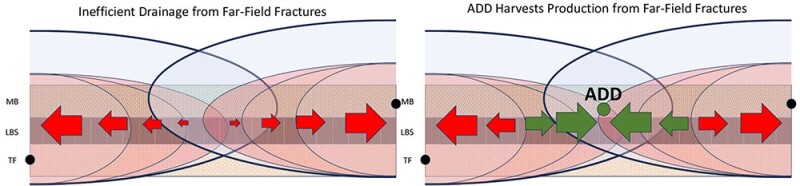

As Cipolla alluded, to skeptics, the idea of using the hydraulic fracturing treatment of one well to adequately stimulate another would seem improbable, if not outright impractical.

But to him and some others on the completions team, the ADD concept made sense for a few reasons. Among the most important involves something operators have consistently observed for the past several years on nearly every multiwell pad in the Bakken—and in all other unconventional plays as well.

That is the well-to-well phenomenon known as frac hits, or fracture-driven interactions, which occur when stimulation fluid and proppant originating from one well breaks through reservoir rock and crosses over another wellbore.

Frac hits behave differently depending on geology and factors such as completion intensity but in general they’ve earned a bad reputation in the shale sector. This is due to their tendency to reduce—or even kill—the productivity of older wells on a pad.

However, this is not so much the case in the Bakken where frac hits have demonstrated a different pattern. Many of the play’s operators, including Hess, have observed that more often than not fracture interactions result in a production uplift from the impacted wells.

At the conference, Rob Fast, chief technology officer for Hess, highlighted that the widespread nature of frac hits and their generally positive outcomes led to a pivotal question being asked within the company about 5 years ago:

“What if we position a well in between the offset wells and we don’t even stimulate it—we just see what’s there by running a slotted liner and try to drain the fractures that exist there?”

With the answer in hand, completions experts at Hess are suggesting that “harvesting” the distant fractures of standard wells with slotted liners may be the key to unlocking even more exotic methods of extracting tight oil.

Merging Emerging Technologies

Beyond integrating ADD wells into typical multiwell pads, as demonstrated in the pilots, Hess is exploring the potential of combining them with multilateral wells.

According to Fast, this approach could reduce drilling costs by utilizing a single vertical wellbore. One lateral could be designed as a standard frac well, while an additional lateral could be placed above or below to capture the offset fractures.

Fast also introduced a different hybrid approach for the 3- and 4-mile laterals that operators have recently begun drilling. He encouraged conference attendees to envision the mutually supporting stimulation strategy where “you have a frac well with an uncemented slotted liner at the end of it, then drill another one back to the other with the opposite configuration.”

Another possibility mentioned in the Hess paper is to merge the ADD concept with the U-shaped well approach introduced by Shell a few years ago. Hess is not actively pursuing this “combo well” design just yet, but modeling work done independently of the oil company has supported the general concept.

In this design, the heel-side of a U-shaped well is completed using a standard hydraulic fracturing treatment, while the opposing toe-side would be completed with the slotted liner.

According to Fast, this could be executed within the same geological bench or designed so that the toe section lands in a lower bench. He said this would offer a cost-effective way to harvest fractures that extend downward into lower layers.

Looking even further ahead, Hess sees the potential for drainage wells to also play a role in enhanced oil recovery efforts in tight rock formations.

The driver behind all this creativity is necessity.

Cost efficiency was not the primary focus during the pilot tests, but Hess has acknowledged that drilling standalone ADD wells presents “challenging economics.”

The company has not revealed any financial figures to give us an idea of what those economics might look like. But it did emphasize in its paper that scaling the concept “will likely require significant cost reductions combined with optimized well placement.”

Testing the Limits

The results from the first ADD well were promising enough to convince Hess management to allow the completions team to follow up with a two-well pilot program dubbed ADD 2.0.

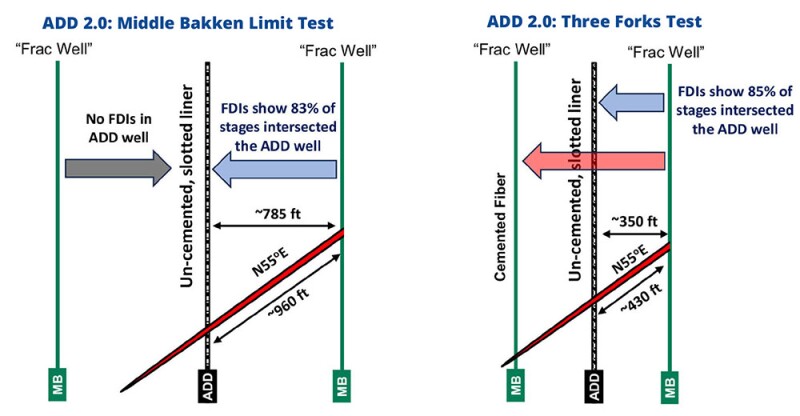

One of these subsequent tests aimed to determine how far a slotted wellbore could be placed from actively stimulated wells and still produce oil.

Drilled into the Middle Bakken formation, the ADD 2.0 well was positioned in between standard frac wells spaced 1,570 ft apart, or about 785 ft from each well.

The 1-year cumulative production of this second Middle Bakken ADD well reached only 11% of the average output of the offset wells. Hess believes that because fractures grow off-azimuth relative to the wellbores, those that ultimately reached this ADD well had to have half‑lengths approaching at least 1,000 ft.

A key difference from the initial Middle Bakken pilot was that the ADD 2.0 well began producing 60 days after the standard wells. This was because Hess said the well needed to be fitted with artificial lift, presumably due to low flowing pressure.

Hess suspects that the delay “suppressed” oil production by allowing the other wells to preemptively deplete or otherwise alter the zone from which the ADD well was also trying to drain.

This aside, Hess considered the limited test a win. It provided valuable data for the modeling effort by showing the degree to which ADD well productivity is a function of standard well spacing.

This was clearly needed given the test contradicts the early models that predicted an ADD well would not produce a drop of oil if standard wells were spaced more than 1,400 ft apart.

The other ADD 2.0 test performed in the underlying Three Forks Shale was less successful due to a stuck packer at the wellhead.

This required the well to be killed with heavy brine. And while attempts were made to remediate the likely formation damage this caused, these took more than a year to accomplish which has made the pilot’s learnings less reliable. By the time the well was brought online it managed to produce only about 8% of the standard wells’ output in its first 2 months.

The Models Were Useful

Like many shale producers, Hess has spent the past several years diagnosing the ins and outs of frac hits across its acreage in North Dakota.

One of the most valuable yet seldom-used tools in this industrywide, due to its high cost, is the observation lateral well. This tool allows operators to directly measure how fractures propagate between wells and how they lose pressure and proppant conductivity while draining the reservoir over time.

Hess drilled one of these observation wells on a highly instrumented research pad in 2019 and in doing so paved the way to the ADD concept.

Fast said the observation lateral equipped with fiber optics and pressure gauges revealed that “we had relatively low conductivity—but some conductivity” within fractures that were about 450 ft feet away from the stimulated wellbore.

This was the key.

When the company put its data on fracture conductivity into the models, they suggested that a passive wellbore could be used to rescue those low-conductivity fractures which remain propped but would be otherwise disconnected from their mother wellbore as closure pressure and multiphase flow effects took over.

Cipolla said the model showed such wells could produce oil, “it just depended on how close they were to the offset frac wells and how big the jobs were.”

One of those early modeling runs indicated that a 4½-in. uncemented slotted liner could produce up to 60% of the output of the standard wells on the pad. This scenario, which involved placing the ADD well 300 ft between two standard wells spaced 600 ft apart, became the template for the first ADD pilot.

The model also earned points here for being reasonably on target given that the first ADD well achieved a cumulative output equal to over 40% of the standard wells on the same pad.

What’s Old Is New Again

Another critical aspect of the ADD concept is its minimalist completion design which was no accident. Once again, the decision to use an uncemented slotted liner stems directly from observations on frac hits.

Recent research suggests that the production uplift seen after frac hits in the Bakken is often due to the understimulation of older, so-called parent wells, compared with modern child wells that are defined by much larger injection volumes of water and sand. When these modern completions are applied, the effect of a frac hit on the parent well can be similar to that of a refrac or restimulation.

However, Hess has identified an additional factor at play.

The company emphasizes the unique impact frac hits have on openhole, or uncemented, completions. These openhole wells—among the most basic and vintage designs from the early days of the tight oil era in the Bakken—have shown the highest production increases after frac hits.

The rationale is that, without barriers to the formation, openhole wells benefit the most because they are more exposed to the crisscrossing fractures from offsetting wells.

Where Hess can and will take its ADD concept from here on is uncertain as the company is in the midst of a $53-billion acquisition by US supermajor Chevron. The deal is currently on hold due to regulatory scrutiny and arbitration claims filed by ExxonMobil and the China National Offshore Oil Company (CNOOC) concerning Chevron’s attempt to acquire Hess and its 30% stake in their Guyana consortium.

Additionally, Hess has not confirmed whether it plans to pursue additional ADD pilots or any of the advanced well designs proposed at the conference. The company has also not sought patent protection for the ADD well, and it remains unclear whether any other shale producers have attempted to replicate the approach.

For Further Reading

URTeC 4044110 Novel Well Design for Unconventionals: Augmented Drainage Development (ADD) by Craig Cipolla, Aicha Kechemir, Michael McKimmy, Khalid Shaarawi, and Robert Fast, Hess Corp.