Hydraulic Fracturing Content Feed

-

Oil and gas extraction using water has opened up new hydrocarbon resources. However they can produce four times more salty water byproduct than oil. Desalination in shale gas and polymer-flood EOR remain niche markets for lowering cost and improving production.

-

As completions activity slows down in the US, the second service company in a week’s time has said it is exiting the business of hydraulic fracturing.

-

The company said it will avoid the pumping business's “structurally disadvantaged position” and instead focus on well servicing and water logistics.

-

ConocoPhillips’ one-of-a-kind test site in the Eagle Ford studied core, image logs, proppant tracer, distributed temperature sensing, distributed acoustic sensing, and pressure, which shows that not all hydraulic fractures are created equal.

-

For the past 20 years, the diagnostic fracture injection test has been used across the frontlines of the shale revolution to paint a picture of what cannot be seen. However, that picture has not always been so clear in the eyes of subsurface engineers.

-

With 2020 on the horizon, JPT editors put together our Top 10 list of technologies and ideas to keep an eye on in the coming year.

-

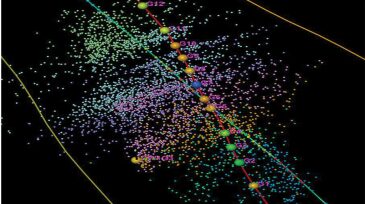

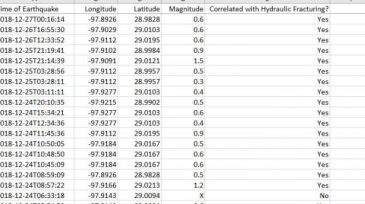

Earthquakes caused by hydraulic fracturing are more common in the Eagle Ford Shale of South Texas than previously thought, a new study reveals.

-

California Gov. Gavin Newsom is cracking down on oil producers by halting the approval of hundreds of hydraulic fracturing permits until independent scientists can review them.

-

New research links a rise in seismic activity in West Texas with increased oil and gas development over the past 20 years and, in particular, the past decade.

-

Fluid saturation isn't what it used to be when it comes to unconventional reservoirs. Our guest is among those sharing new research to discuss the shale sector’s changing perspectives on the importance of mobile hydrocarbons vs. immobile hydrocarbons.