Companies would not normally view abandoned and orphaned oil and gas wells as assets. Historically, this nonproductive and potentially hazardous infrastructure has been labeled a liability without a uniform set of regulations to address its future—and many times without an identifiable owner to hold responsible for it.

California-based Geo2Watts sees these wells differently. The company wants to repurpose these old producers into thermal energy storage systems capable of electricity generation using two chief ingredients: solar power and sand.

The team is led by co-founder and CEO Phil Cruver, who had previously worked in aquaculture and wind energy generation. Bill Bartling is a co‑founder and director of regulatory affairs. He has worked in the tech and oil space, including a stint at Chevron. Ken Murray is co-founder and director of engineering and innovation. He has had a multidimensional career in engineering, research, development, management, and law.

The technology, which the company dubbed the borehole battery, would require new legislation and some permitting, but the company remains bullish on its prospects.

In this Q&A Cruver, Bartling, and Murray share their insights on the technology and their vision for the future.

JPT: Can you walk us through the technology that allows Geo2Watts to utilize idle and orphaned oil wells for grid installations for thermal storage and electricity production?

Geo2Watts: This technology is being developed to transform idle oil well assets into long-duration, on-demand, dispatchable zero-emissions electricity generation to be deployed during low-generation/high-demand energy cycles inherent to renewable generation systems.

For oil well conversions we must first distinguish the differences among the wells targeted for our venture: An abandoned oil well has been permanently taken out of production. The well is permanently sealed, plugged, and buried per state, local, and/or federal regulations to prevent the release of oil, gas, or other substances into subsurface water reservoirs and the environment.

An orphaned oil well is one that has not been plugged and sealed and where the last known well operator is no longer in business, deceased, or cannot be located.

Our company is interested in idle wells which in California are defined as a well that has not been used for production, injection, or subsurface data collection for 2 years or more and has not yet been properly plugged and abandoned. Other states and federal definitions for idle wells include wells producing less than 15 BOED. The concept of repurposing, while concurrently plugging these idle and low-producing wells for generating clean electricity, offers the owners a strategic and lucrative opportunity in preparing for their “end of life.”

After the producing zones of the idle oil well are plugged and the remaining casing is demonstrated to be mechanically and structurally sound, it is filled with a thermal storage/harvesting substance such as phase-change materials along with a novel and proprietary heat exchanger to add and extract heat from the converted well. This effectively converts the well into a thermal energy storage (TES) system.

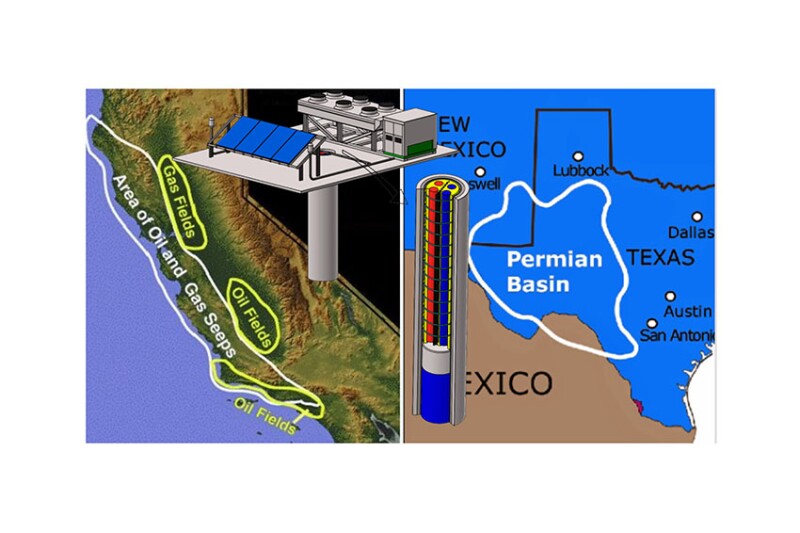

Solar thermal collectors are the source of renewable heat, although heat pumps and resistance heaters may also be used, for heating pressurized water up to 175°C. This heated water is pumped into the TES within a closed-loop heat exchanger to charge the TES. During electricity production, the pressurized water flows through the same heat exchanger of the TES, but this part of the cycle harvests heat and delivers it to the evaporator/boiler of an organic Rankine cycle (ORC) power plant. This heat drives the power cycle to produce electricity.

The optimized design of the TES and its heat exchanger, coupled to the ORC power plant and solar collector field, are the critical components of the closed-loop system called the “borehole battery” which is a patent-pending technology. Research and design are underway to evaluate the best thermal storage substances, heat exchanger design, and optimization of the process for this system.

JPT: You estimate that 37,000 wells in California have the potential to produce electricity with this technology. What are some of the parameters idle wells must meet to be deemed electricity-ready?

Geo2Watts: Our current design assumes 7-in. casing for installing the borehole battery. Some wells, especially shallow wells, may have smaller casing which would require a modification of the borehole battery design. Well depth may play a role in well selection. Our ongoing research will define those limits which will be foundational to parsing out those wells best suited for conversion from the huge current inventory of idle and soon-to-be decommissioned active wells.

The surface footprint of the heat and power generation system that charges and harvests heat from the borehole battery is less than what is required for typical operations that have easements for workover rig access.

Ideally, we want to work with fiscally sound responsible operators for idle oil well conversions. Orphan wells that are not in operation and have no owners of record, can have expensive remediation issues that come with the abandonment. While these wells can potentially be converted, the cost and effort of doing so make them a future opportunity rather than a near-term priority.

There is much written about the projected cost of full Asset Retirement Obligations (ARO) for California’s orphan, idle, and active wells and the reality for this being currently underfunded. Most operators carry a full or partial reserve on their books for paying for end-of-life events for their wells and associated assets. The Investment Tax Credit (ITC) allowance in the Inflation Reduction Act (IRA) provides for up to 50% recovery of capital (see question 6 below) used to convert oil wells to zero-emissions energy systems, such as our technology. Therefore, for companies with ARO reserves insufficient to abandon all their wells, converting the well into a borehole battery may allow fully meeting mandatory ARO.

In parallel, new statutes and regulations are being enacted in California every year that in many cases dramatically shorten the productive life of wells. This may create a situation that affects even those operators who have diligently taken accumulated reserves from production revenues for the eventual abandonment where the shortened producing life of the well may leave their reserve with a shortfall. This conversion program can help these operators meet their abandonment requirements while complying with the new statutes and regulations and contributing to the creation of clean, long-duration, and dispatchable electricity revenue streams.

JPT: How much, if any, leakage is expected from any single well used to store electricity? What about general efficiency expectations such as life-of-well post-conversion and maintenance schedule?

Geo2Watts: As far as gas and fluid leakage out of the well into the atmosphere or underground reservoirs, the hydrocarbon-bearing zones of the wells will be sealed, plugged, and abandoned per state and federal regulations.

Regarding leakage of working fluids in the borehole battery heat exchanger system, we expect none as the downhole heat exchanger is a closed-loop system. In addition, the borehole battery will be installed inside the borehole casing strings, most of which are cemented to the surface. We also plan to install fiber-optic (DAS/DTS) monitoring systems to provide measurements of temperature distribution and changes in the borehole battery and acoustics to detect leaks in the closed-loop heat exchanger. We are modeling the use of water as the working fluid which would not pollute underground reservoirs in the event there was a leak in the heat exchanger.

Water is the preferred vector for transporting heat as it has excellent thermophysical properties including specific heat and heat transfer coefficients. The repurposing of an underground oil well as a TES system provides inherent benefits to the overall efficiency. The multiple thick layers of concrete casing and the geology that the well was drilled into act as potent heat insulators, and the fact that it is buried rather than being exposed to the ambient air (and especially wind) significantly reduces heat losses. Initial estimates of heat losses, over the span of 10 hours, is just 1% of the thermal energy stored. Though more detailed analysis about surrounding soil and downhole geology temperatures is required for higher accuracy, such low values of heat loss make the technology an ideal candidate for long-duration energy storage.

The life of the well post-conversion in large part is dependent upon the state of the well pre-conversion. The conversion of the well and installation of the borehole battery is an industry standard and local regulatory-defined abandonment except for the portion of the well converted to the TES system. The well casing will be tested and confirmed to have structural integrity before converting it to a TES system, and as previously stated, fiber-optic monitoring will be installed to monitor the performance of the TES and provide early warning of any leaks in the heat exchanger. The expected life of the well is not changed from what would be expected if the conversion had not been done.

We expect very little maintenance required as there are no moving parts downhole in the borehole battery. It is possible that the heat exchanger closed-loop system may develop a leak over time which would require pulling the heat exchanger and thermal exchange materials and replacing them. The DAS/DTS will provide both a detailed measurement of temperature distribution and time variant changes throughout the borehole battery volume for optimization of its performance, and the acoustic monitor will provide early detection of any fluid leakage from the heat exchanger. Therefore, maintenance is not expected to be on a scheduled basis but rather as needed to remedy any system failures. As stated previously, the working fluid in the heat exchanger will be water that is contained inside of cemented casing, so the impact of a leak is only to the performance of the borehole battery and will not present any risk to the environment.

Drilling and completion technologies and regulations differ in each state but all hydrocarbon wells in the US are built with industry engineering standard fluid, pressure, and drinking water protection control systems that include cemented steel casing in the wells. Thus, all wells constructed in this manner are candidates for conversion into our technology.

JPT: What additional infrastructure would be needed to move electricity generated by these wells into the market?

Geo2Watts: We will initially target “other-side-of-the-meter” customers in California where the commercial and industrial rates are more than 20¢/kWh and select the ideal wells having existing infrastructure.

In the Permian Basin of Texas and New Mexico, an independent analysis estimated that there are more than 100,000 idle wells that we feel have the potential to be converted to clean sources of electricity to replace natural gas and diesel using its infrastructure for power generation.

Regarding cost of infrastructure and the potential 50% recovery of capital, the Inflation Reduction Act (IRA) provides a 30% base Investment Tax Credit (ITC) for qualifying projects that generate zero-emission electricity. Projects can qualify for additional ITC such as the 10% Domestic Content adder, which applies if a significant portion of the project’s components are sourced from within the US. The 10% Energy Community adder is available for projects located in areas that have historically been involved in fossil fuel production. Borehole battery components are manufactured in the US, and Geo2Watts-targeted locations for repurposing and plugging the idle oil wells meet the Energy Community criterion.

JPT: The borehole battery concept sounds a bit like the ROPES system, which looks to repurpose offshore pipelines as energy storage vessels. Both are novel solutions for aging infrastructure. How do you “sell” the concept past the novelty in the eyes of skeptics and into the practical?

Geo2Watts: The offshore ROPES system addresses a different market, but it is akin to our concept repurposing aging infrastructure for novel energy storage. The ROPES system uses idle offshore pipelines as an energy storage vessel for high-pressure seawater, essentially storing energy in the form of mechanical energy in a compressed fluid.

On the other hand, the borehole battery uses terrestrial oil wells as the containment shell of a TES into which heat is deposited, stored, and later extracted and converted into clean and dispatchable electricity through a thermal power plant.

This is a relevant question because we have been challenged to validate the efficacy and economics of the borehole battery concept and technology by skeptics from the oil and gas, renewable energy, and environmental community. We have found that there is an aversion among renewable energy scientists to revitalizing aging hydrocarbon assets; however there is a valid and interesting use case for plugged oil wells as a TES Carnot battery which is a hot topic in renewable energy research.

The large volume of a deep oil well allows the storage of incredible quantities of thermal mass at relatively low costs as the shell of the TES (i.e., the inner casing of the oil well) is already in place. Moreover, the fact that the oil well is underground and has several thick layers of steel and concrete casing reduces the thermal losses of the stored heat in the TES as compared to a hot tank aboveground that must be constructed with several layers of thermal insulation.

JPT: What stage of development is the technology in? Has there been a successful pilot? Has it been commercially deployed?

Geo2Watts: We are continuing to research heat storage and harvesting materials to optimize the efficiency and financials of the system and are modeling the thermodynamics. In parallel, we are calculating the economics and have filed patents for numerous novel designs. Our research continues for developing novel designs for TES focusing on low-cost, easily accessible, thermally stable, and nontoxic substances. The spectrum of thermal storage materials, each with their own unique characteristics, opens doors for innovative designs for generating enhanced efficiencies.

We have proposals for developing a prototype and are in the process of selecting the location for a pilot project. We are also in discussions with renewable energy developers, oil and gas well owners and operators, and tax-equity investors for structuring commercial scaling employing favorable tax benefits.

JPT: Will this new type of well use require new regulations?

Geo2Watts: California is reviewing new legislation on this topic and will likely promulgate new regulations within a few years if the bills pass. In the meantime, as our well conversion solution is essentially an abandonment, the only well permits required would be either workover or partial abandonment which the state has the authority to issue. Since there is no injection of fluids or gas involved, EPA water-quality permits are not required. There may be local land use or air permits required but as the installation decommissions and removes the surface equipment at the wellhead, the permits should not be difficult to acquire.

JPT: Outside of California, the struggles of the Texas power grid in recent years are well‑documented. Could this technology translate into a new electricity source from, say, idle wells in the Permian Basin?

Geo2Watts: The Texas Railroad Commission oil and gas regulatory agency does not have a category of “idle well” in its database. However, there are five categories of wells including no production, observation, partial plug, shut-in, and temporary abandoned. These wells are initial targets for conversion into a borehole battery, and there are 129,583 wells in these categories.

According to MineralAnswers.com, New Mexico currently has 114,385 wells and only 43% are producing. Comparing this to California’s current idle well inventory, the Permian Basin market potential is significantly larger, and the entire region qualifies as an Energy Community for the extra 10% ITC with the IRA.

The Permian Basin is facing a substantial increase in electrical load demand. According to S&P Global, the demand is projected to rise from the current 4.2 GW to 17.2 GW by 2032. More than a third of the forecast growth is coming from oil and gas operators converting operations and if the current rate of load addition continues, only 55% of the demand forecast will be met by 2040.

Implementing our downhole technology on a large scale would significantly reduce the number of idle wells in the Permian by sealing producing zones to prevent methane leakage and repurposing existing infrastructure. This would also add energy storage capacity for oil production operations by providing on-demand, zero-emission dispatchable electricity during peak hours.