Authors: Gaurav Dixit, Ali Habibi, Renato Rios, and Lavish Garg are members of the TWA Editorial Committee.

The term digital oil field (DOF) has become a buzzword in the oil and gas industry these days, with the mention of it bringing up pictures of computers, flashy screens, and programming to mind. In reality, the concept of DOF goes beyond these. It is the “change” in the way the oil and gas industry works. The concept of DOF is the next evolutionary step for the oil and gas industry.

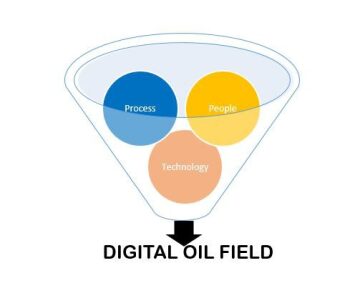

DOF is the integration of technology, process, and people for value creation. This combination was always present in the oil and gas industry but the recent developments in processing speeds, storage capacity, sensors, and the cost of computing have heavily tilted the equation toward the technological aspect.

Technology

Technological innovation has been the main driver for DOF. The building blocks of the DOF are the sensors that stream data and provide digital representations of mechanical systems, for monitoring of oil rigs, refineries, vehicles, and power systems. By introducing technological innovation, we take the humans out of regular tasks and allow them to use his or her knowledge on more creative and analytical work.

Digitization has affected many areas of the oil and gas industry:

Real-time monitoring and control facility. Systems such as SCADA (systems control and data analysis) enable data capturing from on-field sites and send them to the company network. They enable unmanipulated, real-time data to be collected and stored.

Real-time drilling and production surveillance sensors. The collection and integration of real-time drilling data such as drilling rates, pump rates, nonproductive time, and pressure reading can help in quick decision-making. Similarly, using advanced alarm systems to trigger analysis of important production integrity parameters from the wells can reduce response time for well intervention.

4D visualization and modeling. Oil and gas industry generates huge quantity of seismic data. Processing these data takes many man-hours. With the advent of supercomputing processing, it has become easy to process these. Seismic data can be converted swiftly to field models allowing insight into production enhancement, leading to quicker decision-making and field plans.

Process

The DOF is a process of continuous improvement and requires a collaborative environment. The workflow is iterative that gets refined with time and specific requirement. Although there are no fixed workflows for DOF, the essential elements of the process include

- Defining the problem

- Collection of data

- Generating solutions

- Communicating the decisions

- Execution

The process of digitization has to be propagated to the entire value chain to create maximum value.

People

The people involved in DOF are the most important and the most challenging part. The biggest barrier standing in the way of its adoption is the fact that it requires an unprecedented level of collaboration and change across organizational silos. The new digitization era involves upgrading of skill sets and change in the working style. Such a disruption is difficult to handle in an organizational chain. Hence, handling the manpower requires a well thought of strategy.

Companies are encouraging their staff to go for more and more for online data courses as well as hiring professionals from the IT industry. There is a huge demand for data scientists and people with data analytics capability with a background in the oil and gas industry, and this demand is expected to grow exponentially. One of the primary reasons for this deficiency is that not many universities are offering data analytics courses in oil and gas now. As a result, the closest-fit option is being pursued by the companies. It will take some years before this demand and supply gap is bridged.

The Benefits of Adapting to DOF

Improving oil and gas exploration. The areas in which technologies are most potent in increasing access to oil and gas reserves include seismic exploration, enhanced recovery, and wells. Seismic analysis is already benefitting from the use of supercomputers to analyze results quickly and provide highly detailed pictures of oil and gas reservoirs. It is anticipated that further advances in seismic imaging and the processing and interpretation of the vast volumes of data acquired will further improve the speed of decision-making. The BP research team estimates that enhanced oil recovery processes could deliver around 500 billion additional barrels of oil, or a 10% aggregate increase in total remaining recoverable resources, by 2050. The DOF has potential to increase the volume of oil and gas through stimulation, completions, and intervention.

Lowering production costs. According to studies reported in the BP Technological Outlook 2018, by 2050, technology has the potential to reduce average lifecycle costs by around 30% per barrel of oil equivalent across all oil and gas resource classes. The areas with the greatest scope for cost reduction are the most capital intensive, such as deep- and ultradeepwater, and those requiring large numbers of wells, such as tight and shale oil. Deepwater resources can benefit from improved rig and platform design as well as subsea and flowline development.

Improving health, safety, and environment (HSE) performance. Increased digitization will also mitigate risk and prevent HSE incidents, especially in remote or inhospitable operating environments, by reducing the number of workers required to carry out the most dangerous aspects of fieldwork. This will lead to efficiency and precision, and enhance safety, while maintaining production levels at a fraction of the current cost.

Although a tough task, few oil and gas companies have been able to implement DOF. BP has installed a web of sensors and fibre-optic networks across its North Sea, Gulf of Mexico, and other assets to collect and interpret immense amounts of data in over three dozen advanced collaborative environments around the world. Among the benefits, it estimates it has added 3,000 B/D to the Schiehallion Field in the North Sea. Shell says implementation of Smart Fields can increase the total amount of oil recovered from a field by 10% and gas by 5%, as well as boost the rate of production. Petrobras has been successfully implementing digitization in their Carapeba and Campos fields. ExxonMobil has also implemented the DOF approach in many of its fields.

Oil and gas companies stand at a very critical juncture, where at one hand there is a growing demand for energy and on the other hand there is depleting manpower, environmental concerns, and decreasing reserves. The question is whether companies will take advantage of the new DOF nuts and bolts to their success.

References and Further Reading

- An IOC Experience in Implementation of Digital Oil Field Technology, Hacker. M. J., SPE 117837.

- Unleashing Productivity: The Digital Oil Field Advantage. Report by Booz & Co.

- Achieving Digital Oilfield Competency. Pickering, J. G., and Sengupta, S. SPE 167432.

- BP Technological Outlook 2018.