The plunge in well completions has exceeded the drop in the number of active drilling rigs, and operators are rethinking how they fracture wells now that oil is selling for half of what it did 6 months ago.

For Mike Vincent, an independent consultant who teaches fracturing courses, it led to a change in his lesson plans. “One class I am teaching this summer is titled, ‘How should we complete a well in a low-cost environment?’” he said. “We need to do things differently. There should be a different optimal design if a well is drilled when oil is USD 50/bbl versus USD 100/bbl.”

Financially the goal is simple: find a way to earn an acceptable profit on each dollar invested.

“When oil is worth more than USD 100, we can spend more to squeeze those incremental barrels out. When it is USD 50 a barrel, you should spend less money going after incremental opportunities,” Vincent said.

The alternative is to not complete the well after it has been drilled, and there has been a surge in companies making that choice. “The pullback has been a lot more severe than anticipated,” said Brad Baker, vice president of production enhancement for Baker Hughes. “The completion side is even bleaker than the drilling side.”

“We anticipated a decline in completions in 2015, but we have already seen a more rapid drop than anticipated in the first quarter,” he said. There has been a growing backlog of wells drilled but not completed. The reasons for continued drilling include contracts committing operators to pay, even if drilling stops, and lease terms requiring drilling to maintain the lease.

Anadarko reported in early March it had a backlog of 125 uncompleted wells. The company’s chief executive officer, Al Walker, said the company did not “see value in chasing growth” in this environment. He added during the call for investors that the company could stop doing completions and seek concessions from service companies that “will give us I think an opportunity to realize more savings. But we will have to see how the market responds.”

For consultants, advising companies on how to revise completion methods remains a steady source of work at a time when companies are laying off thousands of their workers. While lower oil prices reduced completion budgets, customer expectations have not gone down.

“When I am doing an optimization for a gas well in England gas is selling for USD 10/Mcf, in Canada it is USD 2/Mcf, or USD 3 in the US. It is still the same exercise,” said Tim Leshchyshyn, president of FracKnowledge, which sells data and advice on completion designs.

Doing more with less requires better decisions. “You can be 80% right when there is USD 100 oil,” he said. “They are having to go about actually trying to get the 100% answer.”

In recent days, company earnings calls regularly include executives reporting that completion costs are down and production is up. For example, Marathon recently reported reducing its cost per well in the Eagle Ford by 17%, and increasing its production over the first 180 days by 25%.

A common theme from operators is “back to the basics,” said Brandon Mikael, Lower 48 upstream oil and gas analyst for Wood Mackenzie. “We are seeing standardized methods for completions. They have found the right mix and lock in on it. Standardization is easy to manage from the cost side,” he said. “It is less on how to optimize and more about fixing a program across a broad area.”

The changes come in many forms, with companies following different paths. In shale basins where gelled fluids were a given for fracturing, particularly the Bakken, operators are looking at reducing or dropping the linear or cross-linked gels, and using more slickwater, which is 99% water plus friction reducer and some other additives, such as one to prevent scale buildup.

Sales of ceramic proppant are off, losing market share to lower-cost sand. Some economic evaluations space wells further apart or reduce stage counts as prices fall. And suppliers are hungry for business, allowing users to obtain better quality materials for less. Companies are driving hard bargains with service providers—Marathon reported “securing to date a minimum of USD 225 million in savings.”

While the economics has changed, it has not made unconventional formations any simpler. These extremely tight reservoir rocks vary in unpredictable ways. What has been learned from years of fracturing has led to more tightly spaced wells and fracturing designs pumping increasing amounts of proppant from tightly spaced clusters of perforations. Changing development plans have increased interest in the impact of stress, and inter-well connections, both good and bad, are drawing increasing attention.

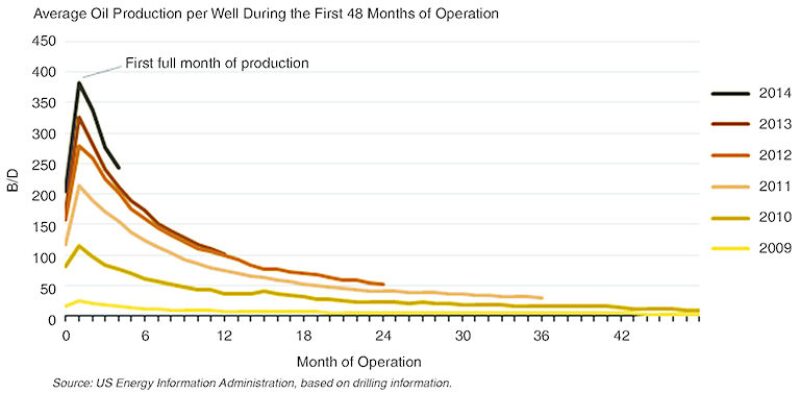

Average initial production rates continue rising, but the decline curve remains as steep. For those championing new technologies, oil selling for half of what it did is reason to totally reconsider how things are done to get more out of fewer wells.

“Because of changes in the market they (producers) cannot afford lower cost and lower production. They want the most effective combination of technology and dollars,” said Matthew Lahman, global product champion for production enhancement at Halliburton. What he is selling is aimed at focusing development on more productive rock and stimulating the tight rock more effectively. “The current market is rapidly driving a transition from factory mode designs to more customized and efficient ones that are delivering higher recoveries and better economics,” he said.

Perceived Value

While service companies see demands for price concessions as a given, there are differing approaches to evaluating completions. “You are going to get some companies that are willing to spend USD 1 to get a USD 4 return in the sweet spots,” Baker said. “And others will spend 50 cents and live with what return they get.”

He breaks the completions market into three segments:

- Large technically sophisticated producers that have pulled back to their prime acreage. This group uses data analysis to better understand their reservoir, and choose development options seeking to maximize the output of the remaining completions. They will also continue to adopt some new methods where they can improve results, including ones aimed at older wells.

- A middle group which is open to using new completion methods, if the added production offers a quick payback on any added costs. Some are using more data analysis to better understand what spending is most cost-effective.

- The most cost-conscious group is taking the hardest line on cost reductions, even if it means substitutions that reduce the ultimate output. This includes some driven by cash flow needs.

For completion engineers the challenge can be summarized in two questions: “How to maximize production” and “How much will that cost?”

Vincent said customers who once asked him to maximize the net present value of wells are now setting price targets. “Some say we need to cut the cost 23%; others will say they want to spend less than USD 7.5 million,” he said.

In this environment spending decisions are made based on tradeoffs between costs and production. Predicting future output is an inexact science, making it harder to accurately predict the revenue impact of any completion option. The effectiveness of a plan is the sum total of the materials, methods, geology, and how well it is executed. “Nothing goes exactly according to plan and the computer program you simulated it on,” Leshchy said.

When production diverges from expectations, experts regularly disagree on the cause. It can be the fracturing fluid, the wellbore, reservoir quality, or some other issue, Vincent said. “In evaluations people can justify decisions pretty often, unless they are looking at large data sets and lots of wells.”

Wave of Change

In the past there were more discussions around using data to drive decisions than there were actual applications, Baker said, adding that he sees more of such numbers-driven thinking as part of a wave of change offering companies opportunities for significant gains in their return on completions investments.

There are companies that are creating those sorts of data sets. Southwestern Energy reported at the recent SPE Hydraulic Fracturing Technology Conference in the Woodlands, Texas, it has created an economic model which takes production predictions and offers objective guidance on issues such as well spacing, which gets wider as natural gas prices fall.

But industrywide, decision makers differ on the effectiveness and cost of various completion options such as slickwater. Clearly, there is growing interest in switching to it in formations where it has been little used before, going by Leshchyshyn’s comment “Every time you look it up, slickwater rises.” He has heard of some Bakken operators switching to all slickwater, while others are using more of it as hybrid jobs where it is pumped first followed by gelled fluid to maximize proppant transport.

At the fracturing conference, speakers from Statoil and Noble Energy said they are looking at moving toward slickwater. Noble has experimented with slickwater at its underground laboratory—wells in a heavily instrumented section of the company’s holdings in the Denver-Julesburg basin in Colorado.

Switch to Slickwater

Switching to all slickwater would mark a significant break from the norm so the companies are moving cautiously. In Noble’s initial test, it only fractured three of the well’s stages with slickwater, said Dave Koskella, exploration and reservoir systems manager for Noble Energy. The results were encouraging—the most productive fracture was slickwater—but production from those stages varied more from stage to stage than the gelled stages, leading to further studies.

The cost comparison between slickwater and gelled fracturing depends on the cost of obtaining and disposing of water. Based on the cost per gallon of fluid, slickwater has an edge. But slickwater fracturing requires pumping two to three times more water than a gelled fluid, because it can transport far less proppant per gallon, which can more than offset any savings on chemical purchases.

A study by IHS PacWest found that slickwater costs, on average, 10% more than a gelled fracture, due to water-related expenses, said Alex Yang, IHS consultant. The higher cost includes the expense of obtaining, transporting, and disposing of the additional water; the additional pumping capacity required to inject it into the well; and the added wear caused by the abrasive sand or ceramic in slickwater, which lacks the lubricating benefit of gel.

According to Leshchyshyn, slickwater costs less. The right answer for any operator will depend on the completion design, what it is now paying for production chemicals, and how it manages the large volumes of water needed for fracturing. Water transport costs far less by pipeline than by truck.

Produced Water

Reuse may also offer a cost advantage. “Slickwater fracturing is changing our strategy on produced water,” said Darren Schmidt, a completions engineer for Statoil. In a presentation at the fracturing conference, he said Statoil’s goal this year is to use 10% produced water in the Bakken. It took 3 years to create the system to efficiently gather, treat, and store produced water, and to do the tests needed to ensure that using produced water for fracturing did not reduce production.

Changes now are bringing the Bakken more in line with other basins where slickwater and sand play a larger role. For example, in places where hybrid fracturing is used, the proportion of gelled to slickwater varies from place to place. In the Eagle Ford, the majority of the fluid injected comes during the slickwater stage, Yang said, which is the reverse of the Bakken where the gelled stage is significantly larger.

Slickwater has always been the norm for formations producing only gas, and in the SCOOP (the acronym used for south-central Oklahoma oil province), “it has been slickwater from the get go,” led by Continental, said Mikael of Wood Mackenzie.

At the same time, Halliburton is commercializing a method for marrying new diversion materials with reduced fluid volumes using high-density slurries of proppant in gelled fluids. It uses a biodegradable material in a way that it blocks off all but the perforation offering access to targeted reservoir zones. The approach, called AccessFrac, promises greater control over where fracturing fluids are injected, with greater design flexibility at a lower cost than the mechanical methods for managing hydraulic fracturing.

“When you distribute material and fluid more evenly in each zone you get a more effective fracture area and conductivity,” Lahman said, adding “you can create added complexity and put added fracture energy into the reservoir.”

Halliburton is now working on documenting the benefits of AccessFrac and other methods to better plan and hold proppant in place after a fracture. It is competing with Baker Hughes and Schlumberger to sell the new diversion methods.

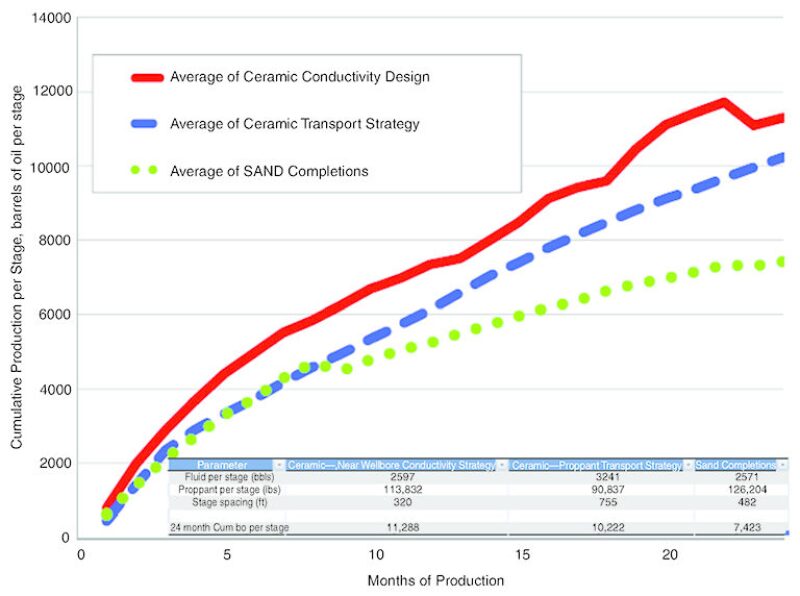

While the big-three service companies work to build a body of evidence for a relatively new approach, an established one, ceramic proppant, is losing ground.

The Bakken formation has been the biggest market for ceramic proppant, because of tests showing it stood up better to the heavy pressures found in the deep wells there. Its share of the market was declining even before the overall market for proppant shrunk, according to a study by IHS PacWest.

“Much less ceramic is being used in general terms and a lot more sand,” Yang said, adding that the trend predates the price collapse. The peak for ceramic sales was in the second quarter of 2014, at a time when the growing number of wells drilled masked the reduced average use per well.

Proppant makers at the fracturing conference talked about the decline. “It is a short-term, cost-driven drop. Most who use ceramic understand the value of ceramic,” said Don Conkle, vice president marketing and sales for Carbo Ceramics, the largest ceramic proppant maker. He said to remain competitive, “We are adjusting our pricing. We believe in feeling the pain.”

Falling demand for all sorts of proppants is also increasing the focus on material quality. Vincent said the strength and size of the sand or ceramic affect the productivity of a well. But when drilling was booming, the choices were limited. Companies used what they could find. “Now there is a surplus of sand and ceramic proppant in the world. There is the potential to be more selective,” he said.

Proppant testing is one of the busiest operations now at Stim-Lab, which is moving employees into that department to reduce the backlog, said Gene Parker, a senior laboratory technician for the division of Core Lab Reservoir Optimization.

Better Execution

The difference between a good completion design and a bad one may be a couple of years. That would be the difference in the period of economically meaningful production for shale wells. When Ibrahim Abou-Sayed, president of i-Stimulation Solutions, describes what he can offer clients, he focuses on slowing the rapid production decline.

“What I am proposing is to have a longer life for a well before we refracture,” he said. “Now, 4 or 5 years into shale development we have to refracture. We can make it 6 years.”

While refracturing is not a new idea, it has been little used in oil-rich unconventional basins, which are just now reaching an age when the production declines could make refracturing an attractive option.

In some places, limiting early production may help slow the narrowing of the production pathways. As the well is produced, the drawdown combined with the load on the well cause rock creep—the slow compression of rock with a relatively high clay content, Abou-Sayed said. As production pathways close, hard proppant can become imbedded in the rock and the well produces less even though the reservoir pressure remains high.

Stronger proppant can stand up to the pressure longer, but Abou-Sayed said the value of the higher-cost proppant varies depending on the mineralogy of the reservoir rock.

The value of a completion design also depends on the quality of the execution. When it comes to oil plays, Vincent said, “Data I’ve reviewed suggests that superior results can be achieved in many oil reservoirs with hybrid or cross-linked fluids in properly designed treatments.”

The qualifiers in that statement include:

- A relatively high concentration of proppant per gallon. Some companies are unwilling to specify those amounts.

- Careful control of the water used to flush out proppant in the wellbore after a stage is done. Too much can lead to overflushing, which can push proppant into fractures away from the wellbore, reducing flows near the wellbore.

Those concerns are not as great with slickwater. “Given the choice of a poorly executed gelled treatment, or a poorly executed slickwater job, often the slickwater treatment will outperform, Vincent said.

For Further Reading

SPE 168744 Declining Frac Effectiveness—Evidence that Propped Fractures Lose Conductivity, Surface Area, and Hydraulic Continuity by M.C. Vincent, M.R. Besler, consultants.

SPE 173343 The Third Dimension: Productivity Effects From Spatial Placement and Well Architecture in Eagle Ford Shale Horizontal Wells by David Holcomb, Randy F Lafollette, Ming Zhong, Baker Hughes.

SPE 173348 Challenging Assumptions About Fracture Stimulation Placement Effectiveness Using Fiber Optic Distributed Sensing Diagnostics: Diversion, Stage Isolation and Overflushing by Gustavo Antonio Ugueto, Paul Thomas Huckabee,Mathieu M. Molenaar, Shell.

SPE 173328 In-Situ Formation of Proppant and Highly Permeable Blocks for Hydraulic Fracturing by Frank F. Chang, Saudi Aramco, Paul D. Berger, Christie H. Lee, Oil Chem Technologies.

SPE 170640 Chemically Enhanced Proppant Transport by Jeffrey Scott Boyer, Darren M. Maley, et al. Trican Well Services.

SPE 173390 Acid Fracturing Shales: Effect of Dilute Acid on Properties and Pore Structure of Shale by Weiwei Wu, Mukul M. Sharma, University of Texas at Austin.