Texas A&M University-Qatar in collaboration with the SPE Qatar Section and its affiliated bodies organized and conducted a 2-day workshop titled "Current Advancements and Future Challenges in Flow Assurance, Carbon Reduction, and Digitalization.” The event was held virtually with the participation of more than 200 professionals associated with academia, research institutes, and industry from 23 countries.

Key Highlights

Over 2 days of intensive discussions, the participants exchanged knowledge and experience on the challenges confronting oil and gas industry in light of stakeholder concerns about the impact of fossil fuels on the global warming, the rapid evolution of alternative energy resources, and the impact of the COVID-19 pandemic on both energy demand and field operations. The participants agreed that demand for hydrocarbons will not disappear anytime soon, but concluded that the oil and gas industry needs substantial transformation from within and needs to embrace changes to maintain its position as the vital energy source worldwide.

Demand for energy, including oil and gas, is increasing globally. It is only the percentage of oil as a fraction of the total supply that is decreasing (Fig. 1).

The long-term growth of renewables and other forms of sustainable energy appears strong. However, it might have a trend very much like nuclear or hydro and plateau after making a significant penetration into the industry.

Not shown in this plot are other forms of incremental energy supply that draw on oil and gas expertise, including waste- and geothermal heat recovery, utilization, and conversion; high-efficiency hybrid gas and solar thermal systems for enhanced oil recovery; and thermo-mechanical energy storage. Oil and gas companies are likely to include increasing levels of renewables in their portfolio either for their own use as power supply or to offer power as part of their product stream.

The participants emphasized on the need for

- A reality check on the probable rate of the energy transition.

- Engaging the public on the growth of global energy demand.

- Rebranding our function more broadly, maybe as ‘we are GeoEnergy’, an industry with an ongoing need for technological innovations.

Considering all of the above, the focus of the workshop was to brainstorm on the envisaged role of Production and Facilities in the upcoming transformation and the prospect that carbon capture and storage sequestration (CCS) would become an integral and critical component of ongoing fossil fuel usage. The changing roles and responsibilities must also reflect the pace of technical advancements, especially the impact of the digital transformation.

Innovations in Production and Facilities

Production operations and Facilities play a pivotal role to ensure a problems-free journey of produced fluids from pore to port. For example, flow assurance engineers need to continuously acquire more knowledge on production system optimization techniques, new materials, chemicals, and emerging technologies, especially nanotechnologies, in order to develop the most optimum operability strategies.

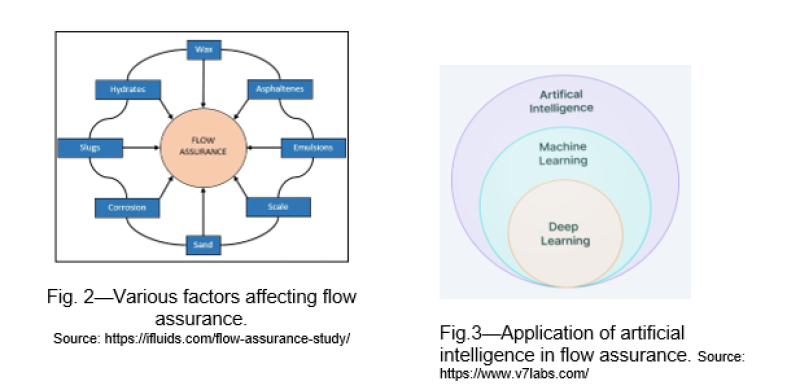

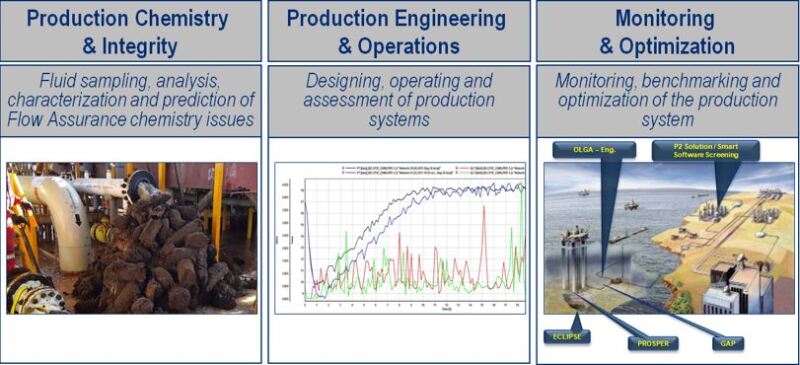

There are currently three main domains of flow assurance engineering:

- Production chemistry

- Production system optimization and corrosion control

- System monitoring and surveillance

Technical advancement in any of the related aspects will strengthen the contribution of this discipline to better understand and address emerging challenges proactively. For example, revolutionary innovations in the field of nanotechnology, nanoparticles, and nanofluids have created a drastic improvement in risk abatement. Additional strategies to combat common solid deposition issues allow for greater production uptime and more flexibility in Capex and Opex management.

Similarly, digitalization plays a vital role for production efficiency and risk reduction. In this respect, data analytics, artificial intelligence, and machine learning expertise is of utmost importance for the future energy industry. The energy footprint should be compared for various packaged production technology solutions such as actively heated pipe and passive insulation, subsea multiphase pumping vs. subsea processing vs. above-surface separation, etc. Energy footprint analysis may span from reservoir management to delivering product to customers or to refinery. Production assurance is funadamental and crucial for the proper design and operation of multiphase production systems (Fig. 4).

Energy Diversification

Flow assurance and operability assessments will be a key input to assessing the feasibility and reliability of the emerging sources of energy supply like blue hydrogen. One of the potential advantages and uncertainties in converting to use blue hydrogen as a fuel is the ability to utilize the existing facilities and transportation infrastructure. Screening studies suggest most can be used for blends of natural gas and hydrogen, but that pure hydrogen may be more of a challenge for some existing piping due to the risks of hydrogen-induced cracking. It will be the responsibility of flow assurance teams to define usage limits, verify the reliability, and optimize performance of the facilities for the changing fluid properties via thorough technical-economic analyses.

Emissions Reduction

On the global greenhouse gas emissions issue, the participants agreed that the challenge is enormous and urgent. There is a close link between climate policy and the potential for litigation and the energy sector. Increasing awareness about carbon intensity and reduction options is one of the keys to making progress towards net-zero emission targets. CCS is one of the options that is gaining momentum and wide-scale deployment of such projects. With appropriate government incentives, CCS could add significant value for the proponents and accelerate progress towards achieving the stakeholder’s carbon-neutral objectives.

Elucidating the fact that about 57% of global emissions come from methane, of which oil and gas contribute 25–33%, the participants developed a consensus on the importance of tackling and abating our methane emissions. In comparison with CO2, methane has a shorter period of life but a far more significant impact on global warming (as one molecule of methane captures 80–86 times more radiation than that captured by a molecule of CO2). Therefore, it is considered inevitable that most companies will move to implement action on this as soon as possible.

Unlocking innovation is the key to accelerating decarbonization. Service companies, regulators, and other concerned parties (like NGOs) need to move quickly to develop more precise technologies to pinpoint intermittent methane venting, leaks, and to detect the impact of weather conditions on flare efficiency.

Digital Transformation

Digital transformation is considered the most significant change in today’s life even though digitization started several decades ago. It has been integrated with the strategic plans of different industries and the oil and gas industry should not be an exception.

Precise data is like a new currency, and its collection and analysis is a new path to value creation. Digitization is now moving from distributed big data collection, transmission, storage, and analysis to local data processing and immediate actuation of system control devices. This requires shifting from traditional organizations with rigid structures and hierarchy towards new operating practices and systems based on partnerships, domain experts, cross-functional teams, ad hoc project management or response teams, etc.

Using field data analytics provides a substantial opportunity for operating cost reduction and energy optimization, because it allows the control system to dynamically respond to operating conditions. Data trend analysis allows the operators to anticipate the changing conditions rather than having to rely on conservative “design case” scenarios. Innovation remains the key to advancing the transformation of the oil and gas industry. We will need to adapt imported processes for integrity inspection, intercompany cooperation, and cross-functional collaboration. Adaptability will shape the future of the industry. Effective collaboration between human and artificial intelligence (AI) will accelerate digitalization and sustainability aspirations. Automated process control will be based on machine learning, AI, human intelligence, and integrated operating systems with local and central control.

Deep-learning-based artificial neural networks are emerging as a key enabler for faster simulation of both subsurface and surface flow behavior and problems. This has resulted in saving both time and costs associated with flow system optimization and management of system upsets. In a heavily regulated industry such as oil and gas, there will always be barriers to managerial and regulatory acceptance of new technology and local control to ensure that process safety protocols are not compromised, regardless of what new technology makes possible in other settings. The aerospace industry is a good model for how to overcome such pushback.

Therefore, it is imperative to prepare “Automation and New Control Process” task forces with strong endorsement, commitment, and involvement of executive leaderships in a top-down role modeling and bottom-up implementation that motivates and mandates acceptance by all parties.

Hence, the industry has to capitalize on its existing manpower through continual professional development and in attracting talented people from other industries and nontraditional disciplines by implementing different strategies. For example, with the implementation of the 4Es (Envision–Enable–Empower–Energize). Universities and research institutes will have a paramount role in preparing the new generation of engineers and both conventional and data scientists to fuel the transformation.

Automating Processes

With the aid of automation, digital twins, data analytics, and other cross-functional technologies (e.g., sensing and imaging), production operations, surface facilities, flow assurance engineering, etc. will be one of the game changers for operators to ensure safer, more reliable, and economically attractive production operations, especially in offshore developments.

Digitalization in combination with production operations reduces downtime and the energy consumed in production operations (termed the energy footprint) very cost-effectively. With a modest investment in endpoint devices and talent deployment, a reduced number of highly skilled flow assurance engineers with experience in data analytics can generate significant savings. For example, trimming unneeded protection cuts down on storage requirements, and substantial revenue increases can enhance production in response to changing weather conditions where production might otherwise be curtailed.

Areas for Further Discussion

The objective of this exercise was to establish a platform for discussions among all stakeholders to probe the most attractive options to ensure sustainability of the oil and gas industry at all levels. Some of the points raised for open discussions were:

1. How can we manage the cultural shift towards balancing the old heritage skills and workflows with the requirements for the new control technologies and anticipated requirements of the energy transition?

2. What is needed in terms of governance and legislation? How can they be coordinated across multiple jurisdictions in order to mitigate greenhouse gases globally?

3. What are the best models to fund the technical developments for cost-effective capture, transport, and permanent storage of CO2?

4. How can we effectively integrate the work of vendors that supply single technology when multiple technologies are needed?

5. How can we scale solutions across global operations when many vendors only operate in one or two regions?

6. How can we balance the utilization of renewable energy sources into the oil and gas industry as a source of own-usage power or as an incremental product line?

7. What is the future of big data and AI in terms of transforming the energy industry?

8. How can we collect, synthesize, and react to emissions and waste heat data measurements from different vendors, regions, and facilities?

9. How can we create vibrant discussions among different disciplines within SPE?

10. What would be the industry’s future strategy to have an autonomous system that will act as a central hub for major decisions?

The SPE Workshop “Current Advancements and Future Challenges in Flow Assurance, Carbon Reduction, and Digitalization” was held virtually on 13–14 October 2021. The corresponding author, Mohammad Azizur Rahman, may be reached at marahman@tamu.edu.