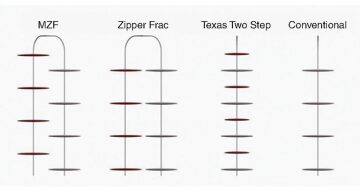

A horizontal well completion method known as zipper fracturing has been rapidly adopted over the last couple of years by companies in the Eagle Ford shale of south Texas. Instead of drilling and hydraulically fracturing one well at a time, the zipper method involves drilling multiple wells from a pad site and then hydraulically fracturing a stage in one well, while getting ready for the next, as wireline and perforation operations take place in another. The multiwell completion method earns its name from the zipper-like configuration of the fracture stages from wells drilled with relatively tight spacing.

This shaves days off the time it takes to complete a multiwell pad. Many companies in south Texas are now using the completion method on almost every new pad site they drill into, saving tens of millions of dollars per year while accelerating the development of their well inventories.

But the big prize may be that zipper fractures are increasing initial production and estimated ultimate recovery rates when designed so that the fractures stimulate the most reservoir volume possible. Tulsa-based WPX Energy, an independent operator of 160,000 acres in the San Juan Basin of New Mexico, told investors this summer that when the company switched to zipper fracturing, it averaged 420 B/D of oil production compared with 388 B/D from single-well completions. While not entirely sure if zipper fracturing is the direct cause of improved production, WPX said it expects that is the case.

Mukul Sharma, a professor and chair in the petroleum department at the University of Texas at Austin (UT), said field data from Eagle Ford wells make it clear to him that zipper fractures are indeed improving initial production rates and the estimated ultimate recovery. Sharma said operators in south Texas have reported improved initial production rates ranging from 20% to 40% using the zipper method. “I would say that this is definitely the way people are going to be doing a lot of their fractures in the future,” he said. “What I think we need to do is understand better how it works—why it works. Once we understand that, we can apply it much more efficiently.”

Marathon Oil first tested the zipper method in the Eagle Ford shale 2 years ago. Today, at least 95% of the company’s pad wells are being completed with zipper fractures. This is saving Marathon an average of 4 days in completion time per pad. “Anything with two or more wells, we will zipper frac,” said Richie Catlett, completions engineering supervisor at Marathon. “From a completions standpoint, for us the main thing is efficiency. It cuts days off our operations, and that is the big reason we went to zipper fracs.”

The Eagle Ford is also where Schlumberger is doing its highest share of zipper fractures, but the company said there is significant momentum behind its adoption outside south Texas, including in the Permian Basin of west Texas and Williston basin in North Dakota. “Nearly half of the completions that we do today in North America are completed with what we call the zipper-fracturing method,” said Alejandro Peña, global chemistry and materials portfolio manager at Schlumberger.

As the use of this method spreads, the Eagle Ford shale remains the uncontested zipper-fracturing capital of the world. Two-and-a-half years ago, less than 25% of Halliburton’s completion operations in the Eagle Ford were zipper fractures. Since then, that share has grown to 85%. Bill Melton, a completions sales manager at Halliburton, said operators have been inspired to adopt the method more for its completion efficiencies than for its potential production benefits.

“By doing zipper fracs,” he said, “a customer can do six to eight frac stages a day. Whereas if they did each well for the entire length, and then switched over to the next well, they could only do three-and-a-half to four stages a day.”

Halliburton has even taken the zipper method south of the US border into Mexico for Petróleos Mexicanos, more commonly known as Pemex, where unconventional shale exploration remains in its infancy. The company believes that this could help develop Mexican shale fields, and those elsewhere, relatively quickly compared with the Texas experience, which took years of trial and error to achieve the near-record production levels seen today. “It takes advantage of all the learning that has already been done, and it accelerates their development cycle time,” Melton said. “Where it may have taken a year for a US operator to get to a 50-well volume, if they are doing pad drilling and pad completions,” non-US operators could be there in a third of the time.

Changes and Challenges

Companies using the zipper method have had to make a few operational considerations that do not apply to single-well completions. When completing horizontal wells one at a time, once the fracturing job in an individual stage is finished, the wireline operation to set plugs and perforate the next stage in the wellbore normally takes 2 to 3 hours, though it can last for as long as 5 hours between stages.

Clifford Phillips, an advanced drilling engineer at Marathon, said when doing zipper fracturing the break in stimulation operations may only last 15 minutes as workers switch from one well to another. “It is a big change operationally for the frac crew,” he said. “They go from having a huge amount of dead time in between fracs to almost no time at all.”

The constant rate of high-horsepower pumping has a downside for service companies; their pumping trucks are lasting about half as long when working on zipper fractures. Catlett also said zipper fracturing allows service companies fewer opportunities to perform maintenance on in-between jobs. “They have to either provide more pumps, which is getting to be a problem with the industry right now, or they are going to have to provide more efficient pumps that can last longer,” he said. “It is a challenge.”

With a lot of the extra workload shouldered by the service companies, one challenge for the operator is to make sure that a steady stream of sand or proppant is arriving to the pad site to keep up with the continuous fracturing. Marathon engineers said they like to keep enough proppant on site for at least four or five stages so that if there is an interruption in deliveries, the fracturing crew can keep moving, which increases truck traffic into and out of the pad site substantially.

There are some limitations to deploying the zipper method. On a five-well pad Marathon will only zipper fracture three wells at a time, and then the next two. This is because the crane it uses for the wireline operations only has a radius of 90 ft while the wells are spaced out at approximately 25 ft to 30 ft.

In terms of extra equipment, the only added system requirement is what is called a zipper manifold, which Dennis Donovan, completions engineer at Marathon, described as a “frac stack” turned on its side that redirects the fracturing fluids into different wells. “That way we are going down the line from one well to the next,” he said. And the cost of the manifold is easily offset by the money saved in rig time and other rental equipment.

Time Delay Critical

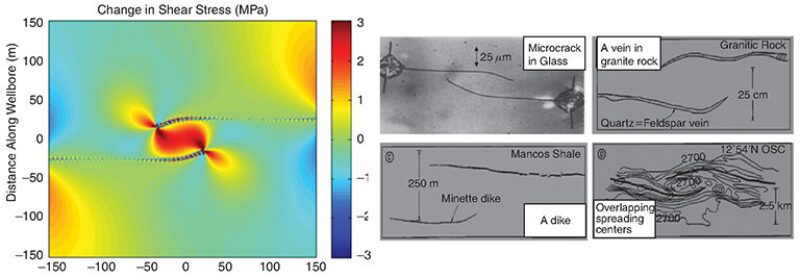

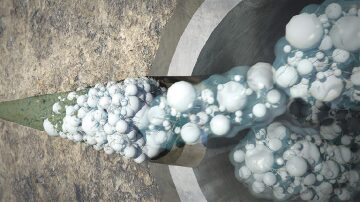

When hydraulic fractures propagate into a formation, a stress shadow is created inside the rock that acts like a force field, hindering the fracturing of another stage. As the fracture closes, the spatial extent and the magnitude of the stress shadow is reduced.

Sharma has been studying the role that induced unpropped fractures play in unconventional development for years and has found evidence suggesting that they not only exist, which has been a subject of debate, but they also penetrate into the rock farther than the propped fractures do. He said production history matching, tracer technology, and microseismic monitoring all indicate that induced unpropped fractures tend to form around the propped fractures and then close in a relatively short period of time.

This is important because Sharma believes it is the reason why zipper fractures work. “The stress shadow you see right after you frac the well can have a fairly large spatial extent, but over time this stress shadow will become confined to a region around the main fracture as the induced unpropped fractures close,” he said.

Allowing the stress shadow to shrink is believed to make fracturing the subsequent stage in a horizontal well more effective because there will be far less stress interference in the rock from the previous fracture blocking the new fractures.

When hydraulic fractures are closely spaced, the stress shadow effect can lead the fractures to grow away from one another and towards areas of lower stress, which may mean less rock is stimulated. To reduce the effect of the stress shadow, Sharma said some operators are doing four-well zipper fracturing instead of two-well.

“You can do Well 1, then 4, come back and do 2, and then do Well 3,” he said. “People have tried that and it seems to work.” By applying the method to four wells instead of just two, Sharma said the time delay between two adjacent fractures in the wellbore can be extended by a factor of five or six.

One way operators can plan and design for this is by using modeling software that includes the stress shadow effect from adjacent wells. In the past, most commercially available fracturing software modeled one well at a time. Over the past 2 years, Sharma said companies have realized that modeling horizontal well fractures in isolation is insufficient when planning for a zipper-fracturing program. As a result, UT now offers operators software that is able to model more than 100 fracturing stages in a multiwell pad.

Safety Considerations

From the service company’s perspective, Halliburton said that the technical hurdles to move from a single-well completion to a multiwell completion, such as in zipper fracturing, are not all that high. Although, the fast-paced operations, extra equipment, and personnel do increase the level of planning needed for a zipper fracturing. “It is really a tremendous exercise in collaboration and optimization to pull some of these very massive jobs off at a very intense rate,” Bill Melton, a completions sales manager at Halliburton, said.

Regarding safety, there are other considerations to make as well. One involves preventing a radio signal from errantly inducing an electrical current that might prematurely fire one of the perforating guns used to punch through the casing and into the formation using an explosive shape charge. Halliburton developed its own radio-safe detonators and perforation guns to minimize the risk of an accidental detonation. In a zipper fracture, there are multiple guns that might go off because of an errant radio signal.

Clifford Phillips, an advanced drilling engineer at Marathon, said the company has also implemented its own safety practices at its pad sites to protect workers. After testing the zipper method, the company realized that it could be done safely but it wanted workers to pay even closer attention to the increased number of high-pressure lines to ensure that they are not near people while they are working. “You have to make sure that the wireline guys who are working together with the frac guys are never around each other when there is pressure in the lines,” he said.

Zipper Mechanics

Neal Nagel, chief engineer and principal at Houston-based OilField Geomechanics, started studying zipper fractures several years ago when operators needed help in figuring out why the completion method has increased production for some, but not for others. He said the big question that operators want to know is why does the interaction between two wells potentially increase production?

“There is a strong link between a hydraulic fracture and the natural fractures, and from a geomechanical perspective, we were looking at that,” he said. Using a series of numerical tools, called discrete element models, Nagel simulated and evaluated the interaction of hydraulic fracturing with natural fractures. Instead of doing this with a single horizontal well, the simulation was run with a dual-well configuration. What Nagel concluded from his geomechanical evaluations is that there are three primary factors that dictate how well a zipper fracture may perform. They are:

- Existence and conductivity of the natural fractures

- The impact the stress shadow may have on hydraulic fracturing between two wells

- Ability to change the pressure within the natural fractures between two wells

“It is those three issues combined that we think are the foundational and important issues when zipper fracs work,” he said. “When they do not work, one of those three things is essentially missing.”

Without natural fractures, Nagel believes that zipper fractures will have zero impact on production. He said one of the reasons that the zipper-fracturing method has taken off in the Eagle Ford shale more than in other areas is because of the prevalence of natural fractures. Unlike in the Barnett, Bakken, Marcellus, and Haynesville shales, operators in the Eagle Ford have reported more pressure communication between adjacent wells. This suggests that natural fractures in the Eagle Ford tend to exhibit greater communication over a longer range than in many other shale plays.

“For those situations like the Marcellus and Haynesville, where it is very uncommon to see operators report pressure communication between wells—that tells you the natural fracture system is not as pervasive or not as connected,” Nagel said. “That would mean that you are not going to be able to change the pressure between two wells. And without that pressure change, a zipper frac is unlikely to show much benefit.”

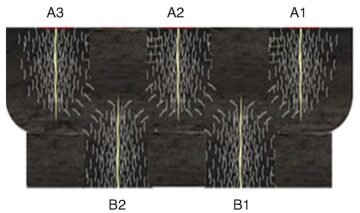

Also, to achieve a positive production outcome, the wells must be properly spaced, and the fractures need to be long enough so that they touch and overlap with one another, thus ensuring there is communication between adjacent wells.

An SPE paper published by Halliburton this year, which evaluated the benefit of zipper fractures in unconventional reservoirs ran simulations that showed when zipper fractures overlap the incremental recovery factor was in the range of 15% to 20%, compared with zipper fractures that do not overlap.

Based on the field data and case study work he has done, Nagel is convinced that pore pressure is the most important factor leading to a zipper fracture that nets higher stimulated reservoir volume and thus production. “When I create a hydraulic fracture, I am injecting at a pressure higher than the minimum in-situ stress, which, by definition, has to be greater than my pore pressure,” he said.

The effect of the increased pore pressure is that the natural fractures are induced to slip more, thereby increasing the permeability and flow capacity of the source rock, as Nagel’s research suggests, and is responsible for the higher productivity in zipper-fractured wells. He said these subsurface events can be detected and observed using microseismic technology.

“When zipper fracs work, we have a configuration where the pressure increase from the first well increases the pressure in the region of the second well,” Nagel said. “When we frac that second well, what it (increased pressure) does is make it easier for the natural fractures and weakness planes to slip; we see greater microseismicity, we see increase in flow capacity, and we see an increase in production.”

Modified Zipper Fracture

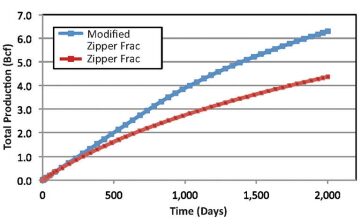

Before Mohamed Soliman became the chair at Texas Tech University’s petroleum engineering department in 2011, he worked for Halliburton for 32 years and holds 26 patents on hydraulic-fracturing technology. One of the patents that Soliman received while at the company was for the alternating fracturing, a precursor to the more efficient modified zipper fracture, which also was designed to breakup as much rock to create more complex fracture networks.

“We came up with alternating fracturing which is done from one well. You create a fracture, then you create another fracture, and then you go in the middle to create another fracture,” he said. “Needless to say, operationally this is not exactly what you would want to do.”

Soliman explained that technology has been created to lessen the complications involved with fracturing stages out of sequence but there are too many operational complexities to work through. “It can be done, but it is a headache,” he said.

When Soliman got to Texas Tech he and his research students took a look back at alternating fracturing and also the emerging zipper-fracture method to see if there was a way to net similar production results from alternating fracturing, but without the operational complexity.

What they ended up inventing was the modified zipper fracture that differs from a normal zipper fracture. Rather than having the fractures of two adjacent wells pointing toward one another, they are staggered so the fractures will overlap with one another. Soliman said that with the modified zipper fracturing operators get the benefits of alternating fracturing without all the extra work.

“You probably will have to have your horizontal wells a little closer than you would have in a regular zipper frac, or you create a fracture that is a little longer,” he said. “Another issue is that it will require more engineering work ahead of the drilling. You need to acquire some data, and do your homework.”

Soliman said he and a graduate student have created a simulation software to further study fracture attraction. The software has not yet been commercialized but Soliman said he expects to present it at future SPE conferences.

One of the most intriguing aspects of the overlapping fractures that Soliman has observed is that as the fractures propagate towards one another, once they are in very close proximity, they begin to show an attraction. Soliman said he has recently completed research work on this phenomenon and will publish the results later this year.

“If you have fractures coming fairly close to one another, they will actually turn around towards each other,” he said. “It is very interesting. It looks almost as if it does not make sense, but when you think about the calculations of how stresses change—it does.”

Diversion Technology Complements Zipper Fractures

A primary driver behind the adoption of zipper fractures has been to reduce the money and time spent completing a series of wells. Service companies such as Schlumberger are now incorporating ancillary technologies, such as diverting agents to boost the efficiency of zipper fractures even more. The fracturing technology is called BroadBand Sequence by Schlumberger, and involves a diverting agent made of biodegradable composite particles and fibers, and is also used in refracturing operations where it is difficult or impossible to re-enter an older well to set and remove plugs.

In most fracturing operations, be they multiwell or single-well, mechanical devices such as bridge plugs are used to isolate each stage so that the hydraulic pressure flows into the targeted interval. The process is continued systematically along the length of a horizontal well. By using a diverting agent operators save several trips in and out of the well with wireline and coiled tubing units to set and then mill out the plugs. Other service companies, including Weatherford, Halliburton, and Baker Hughes have also developed their own diversion fluids for stimulation operations.

In addition to saving on completion time, Schlumberger touts its ability to help improve oil and gas production by increasing the reservoir contact of the stimulation operation. This year Marathon and Schlumberger co-authored an SPE technical paper detailing a case study of a zipper-fracturing operation in the Eagle Ford shale, which showed the incorporation of a diverting agent improved production by about 20% compared with an adjacent well that used the same completion parameters, minus the use of the BroadBand Sequence technique. Alejandro Peña, global chemistry and materials portfolio manager at Schlumberger, said that the net production gain seen in the case study is an average result for horizontal completions.

When using its newly commercialized technology, the company follows a prescribed workflow to assess how much composite material is needed and then the crew pumps it downhole. “We have at the wellsite a dedicated pump, which connects at the discharge of the fracturing fleet before you enter the wellbore,” said Peña. “We inject the (composite material) right at the end of the fracturing treatment to basically provide temporary isolation in the fractures that have just been stimulated.”

The company introduced BroadBand Sequence in February and reported that the proportion of completions that it is used in is already in the “double digits.” It did not provide a figure.