HP/HT

-

When confronted by extremely hot wells drilled into hard rock, engineers start looking for new tools and then ask, is there a cheaper option?

-

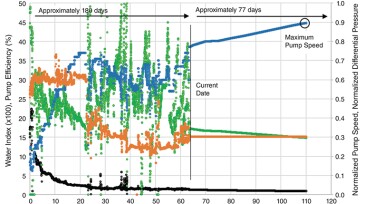

This paper presents a proposed condition indicator that estimates the wear experienced by an all-metal progressing cavity pump at any point in operation and takes into consideration the effects of downhole operating conditions.

-

The array of papers received for review this year covers a wide spectrum, both in applications and research, which indicates that the exploration and production industry is actively working to monetize high-pressure/high-temperature reservoirs.

-

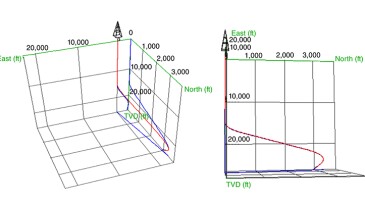

This paper describes an openhole wireline-logging operation in a deepwater Gulf of Mexico well in a high-pressure/high-temperature slimhole environment using water-based reservoir drilling fluid.

-

The paper presents predicted vs. measured wear for six wells in the Culzean field, a high-pressure/high-temperature gas condensate field in the central North Sea.

-

This paper reviews the successful application of a mud-cooling and managed-pressure-drilling system in a high-pressure/high-temperature well to explore the potential of a Mesozoic carbonate platform in the Nile Delta of Egypt.

-

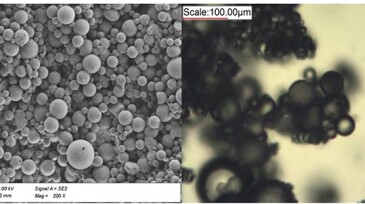

In this paper, β-cyclodextrin polymer microspheres, generally used for drug release and wastewater treatment, are evaluated as an environmentally friendly ultrahigh-temperature filtration reducer.

-

This paper describes the qualification and first deepwater drilling application of a novel aqueous reservoir drilling fluid at temperatures greater than 320°F.

-

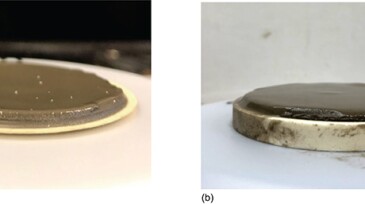

This paper describes a high-density high-pressure/high-temperature brine-based drilling fluid that provides long-term stability and solids-suspension properties for extended periods of time.

-

The authors describe the applicability of 110,000-psi yield-strength quench-and-tempered coiled tubing strings in high-pressure sour environments through implementation of a custom-fit coiled tubing integrity and risk-mitigation program.