HP/HT

-

The Bureau of Safety and Environmental Enforcement is proposing regulations that would improve operational safety, human health, and environmental protections offshore, while providing clarity to industry regarding the bureau's review of projects proposing to use new or unusual technology, including equipment used in high-pressure/high-temperature environments.

-

What a difference a year can make. Oil and gas prices have reached and stabilized at levels that have not been seen for over half a decade, demonstrating that the adage “low oil prices are the remedy of low oil prices” is still true.

-

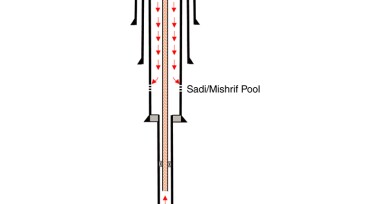

The authors discuss a production strategy in which high-gas/oil-ratio crude can be injected into the upper oil reservoirs with partial pressure depletion to achieve production enhancement and synergy among reservoirs.

-

The paper presents the challenges faced and overcome while drilling and testing a high-pressure/high-temperature sour-gas well offshore in an environmentally sensitive environment.

-

This paper presents a well-integrity-management system developed for a high-pressure/high-temperature gas field in southwest China.

-

Fluid identification, a critical process in fluid sampling, continues to be a challenge in temperatures above 350°F. At temperatures up to 450°F, fluid identification is currently achieved by bubblepoint and compressibility measurements, which cannot quantitatively measure contamination levels of the sample fluid. A possible solution involves using pyroelectric detect…

-

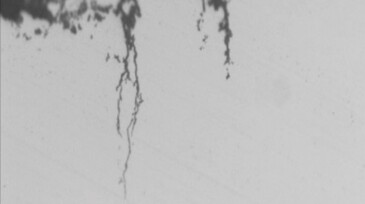

S13Cr tubing specimens experienced stress corrosion cracking with phosphate-based completion fluids contaminated with mud and oxygen, whereas formate-based completion fluid is compatible with the tubing.

-

The paper outlines specific issues, mitigation steps, and lessons learned during the development phase of a corrosion-resistant alloy pipeline.

-

High-strength, sour-service-grade carbon steel has been developed with outer diameter up to 23 in. and wall thickness up to 2.5 in. using a robust manufacturing process.

-

The two companies have collaborated since 2015 on various projects, but COVID-19 brought Velentium and Oasis Testing together for a unique purpose—to quickly ramp up the manufacturing capacity for critical, life-saving ventilators.