predictive maintenance

-

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

-

Real-time location systems have emerged as invaluable tools for enhancing safety and efficiency in the operations of oil and gas organizations. This paper investigates the various applications of the technology within the industry, highlighting its transformative effect on safety protocols and operational efficiency.

-

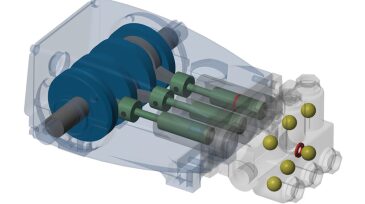

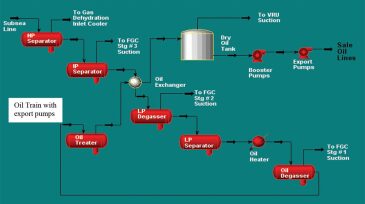

This study examines the implementation of a predictive maintenance method using artificial intelligence and machine learning for offshore rotating production-critical equipment. Conducted over 2 years at Murphy Oil’s deepwater platforms in the Gulf of Mexico, the project aimed to detect equipment issues early, reduce downtime, and streamline maintenance processes.

-

Oil and gas operators such as Shell and Oxy are now employing AI together with a vast network of sensors and other machine-learning software to stamp out problems before they happen.

-

Peter Bernard, CEO of Datagration, discusses how oil and gas industry predictive maintenance doesn’t just provide an economic value, it also boosts safety by anticipating unpredicted failures among aging infrastructure.

-

C3 AI reported that the oil major has hit the milestone of 10,000 pieces of equipment being monitored by its predictive-maintenance artificial intelligence.

-

The Abu Dhabi National Oil Company announced that it has completed the first phase of its large-scale multiyear predictive maintenance project, which aims to maximize asset efficiency and integrity across its upstream and downstream operations.

-

Often it is too difficult to create the fault conditions necessary for training a predictive maintenance algorithm on the actual machine. A digital twin generates simulated failure data, which can then be used to design a fault-detection algorithm.

-

This paper describes an automated work flow that uses sensor data and machine-learning (ML) algorithms to predict and identify root causes of impending and unplanned shutdown events and provide actionable insights.

-

ADNOC will utilize Honeywell’s asset monitoring and predictive analytics platform to improve asset efficiency and integrity across the operator’s upstream and downstream businesses.

Page 1 of 2