Electrical-submersible-pump (ESP) technology is a proven artificial-lift method for shallow, low-pressure reservoirs such as those found in the West Sak viscous oil field in Alaska. However, the unconsolidated nature of the West Sak sands challenges the long-term lifting performance and reliability of conventional ESP systems. The case study in this paper includes the analysis of the two generations of rigless ESP systems, quantifying the success rate in varying conditions in more than 300 rigless ESP replacements in a high-sand, high-deviation environment on Alaska’s North Slope.

Through-Tubing (Rigless) ESP Technology: Generation 1 and Generation 2

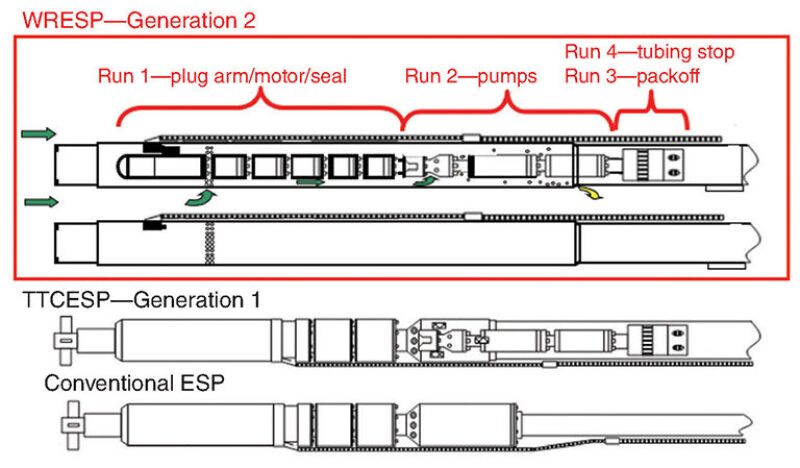

In 1998, the operator developed through-tubing-conveyed (TTC) ESP (TTCESP)/TTC progressive-cavity-pump (PCP) (TTCPCP) technology to allow failed pumps (ESP or PCP) to be replaced quickly and economically using conventional equipment without a rig. In this first-generation rigless ESP system, a rig deploys conventionally, on tubing, the electric cable, motor, and seal sections, with a special latching device that allows the pump (only the pump, not the motor or seal) to be pulled and replaced by use of slickline (SL) or coiled tubing (CT), without a rig.

In 2014, a second-generation rigless ESP system was introduced that added the ability to deploy and retrieve the motor and seal using conventional SL equipment, leaving full-bore access to the lower completion and producing zone.