Artificial lift

Field results highlight how rethinking tubing-anchor-catcher design can reduce gas interference and support late-life production.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

Operators are turning to new gas-lift and nanoparticle-fluid technologies to drive up production rates.

-

Industry experts advocate for collaboration to develop and test technology that can reduce emissions without breaking the bank.

-

The industry is balancing brains and bots as it squeezes out barrels of oil production.

-

Machine learning is refining gas lift production optimization with scalable automated workflow.

-

This paper discusses a new type of mechanical gas separator for electrical submersible pump systems that increases operating flow range and separation efficiency while decreasing erosion problems and improving reliability.

-

This paper presents an approach using artificial neural networks to predict the discharge pressure of electrical submersible pumps.

-

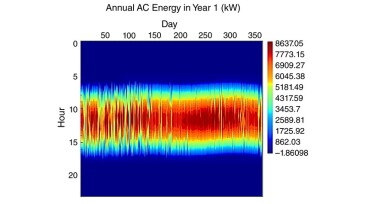

This paper aims to analyze the relevance of wind and solar energy for the supply of artificial lift systems on offshore platforms in the Brazilian equatorial region.

-

Longtime leaders in artificial lift discuss and share their insights on the rapidly evolving segment’s past, present, and future.

-

There will always be a need for good artificial lift engineers. So, what should the next generation of its professionals be trying to pursue?

-

The papers described here focus on novel unconventional horizontal downhole pump card signatures, carbon reduction through alternative energy to pump wells, and predicting downhole-discharge pressure of ESPs.

-

The world of artificial lift has witnessed a remarkable revolution over the past 25 years, with many of the events and technology trends recorded in the Journal of Petroleum Technology.