Casing/cementing/zonal isolation

This paper expands the understanding of geopolymer/microsphere interactions and presents design considerations for alternative cementing materials under low-temperature regimes.

This paper describes an alternative lower-completion concept for developing Lower Wilcox reservoirs referred to as high-angle multifractured well design.

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

-

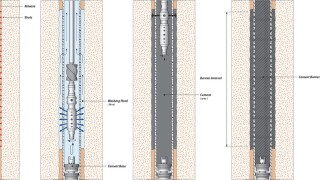

The operator of an offshore jackup rig in the North Sea required safe and efficient deployment of the completion string without killing the well during tripping.

-

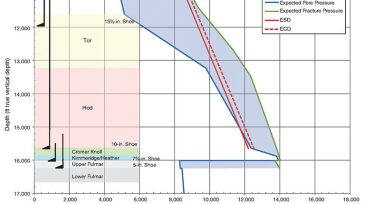

The Shearwater field is a deep, high-pressure/high-temperature (HP/HT) reservoir located in the UK Central Graben of the North Sea.

-

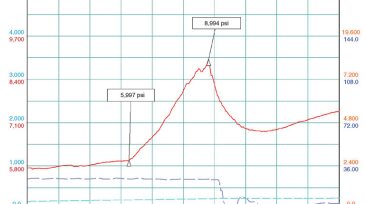

What is observed when an unconventional well is fractured is often at odds with what was expected by those who planned the job.

-

There are headlines every day that discuss the ethics and safety behind oil and gas operations, particularly hydraulic fracturing.

-

This study examines the effects of drilling, completion, and production operations and their associated cyclic stresses on a cement sheath.

-

One approach to refracturing involves the use of mechanical diverters such as perforation balls and rock salts, which may be useful for one stage; however, cessation of pumping operations results in these diverters falling out of the perforations or dissolving.

-

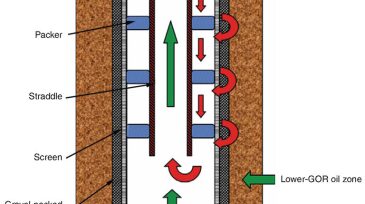

An operator successfully executed two wireline through-tubing gas-shutoff (GSO) workovers in high-angle openhole-gravel-pack (OHGP) completions to isolate high-gas/oil-ratio (HGOR) zones, resulting in significantly increased oil production.

-

Our industry’s demonstrated ability to innovate and continually improve well-construction technology will be all the more valuable to all plays if low oil prices persist, but especially so for shale and other high-cost-per-barrel plays.

-

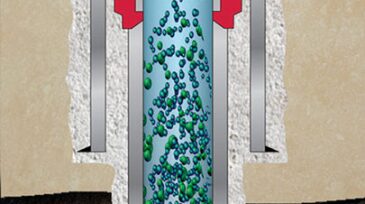

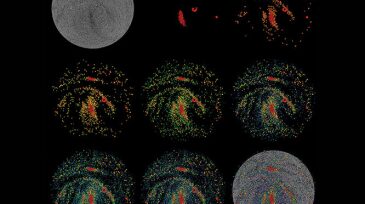

An ongoing research project started nearly 3 years ago by the US Department of Energy’s National Energy Technology Laboratory (NETL) is shedding new light on what really happens to foamed cement as it is pumped deep down offshore wells during completions.

-

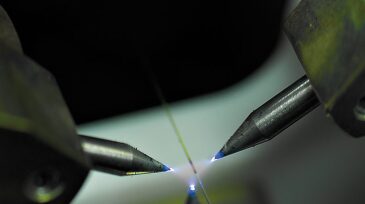

It has been an impressive comeback for a technology that once stood on the brink of failure. The upstream oil and gas industry has largely resolved crippling technical challenges that shortened the life of fiber-optic cables in downhole applications and is now working on a big encore.