Directional/complex wells

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper presents a study of trapped-torque incidents during drillpipe connection, highlighting contributing factors and root causes and proposing prevention and mitigation measures for these transient events.

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

-

The Peregrino project, located in the post-salt zone of the Campos Basin, presents immense challenges for drilling extended-reach wells. This paper shares challenges imposed by the well profile and downhole environment on the design and execution phases.

-

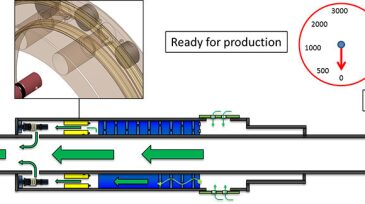

This paper presents a concept that enables simultaneous drilling and completion, with an aim to extend well reach substantially and with an ultimate objective of constructing 30-km-long production wells.

-

Advancements in extended-reach drilling continue from the ExxonMobil-operated Sakhalin-1 project. The latest “super complex” horizontal well stretches 15,000 m, which partner Rosneft says is a “world record.”

-

new drilling method provides a solution for challenges encountered in drilling of long horizontal wells, incorporating a dual drillstring with a separate channel for the return fluid from the well.

-

If it has been proved in the past that innovative technology is excellent for bringing more-efficient solutions to reduce costs, will digital technology be the panacea for the whole industry?

-

The purpose of this paper is to demonstrate how inaccuracy in standard directional-surveying methods affects wellbore position and to recommend practices to improve surveying accuracy for greater confidence in lateral spacing.

-

The complete paper discusses the advancements in mud-displacement simulation that overcome the limitations of the previous-generation simulator and provide a more-realistic simulation in highly deviated and horizontal wells.

-

The boom in organic shale plays has revealed the critical need to size hydraulic-facture treatments correctly to achieve commercial success.

-

This paper discusses the first deployment of an ICD system combined with an OBC system for a workover operation in a mature producer well in the Kingdom of Saudi Arabia.

-

Software that offers turn-by-turn directions for drilling a horizontal well could drastically reduce the number of directional drillers.