Drilling

Malampaya East discovery is estimated to hold 98 Bcf of gas and may help offset declines at the country’s only producing gas field.

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

-

This paper presents an evaluation of geopolymer cementing for use in oil and gas wells, specifically in the primary cementing of liner strings in the Permian Basin.

-

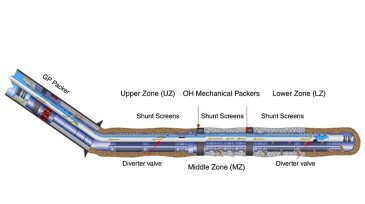

This paper presents the completion strategy implemented in an intelligent well completed in Malaysian deepwater Block K.

-

Private explorer Rhino Resources has tapped the oil services giant for upcoming Orange Basin campaign.

-

The latest signs that momentum is building in the geothermal space include military bases.

-

As the biggest US companies grow bigger, the advantage of scale becomes clearer.

-

The national oil company credits lean operating practices and AI for making the three-well, 45,000 B/D project economically viable.

-

SponsoredExpanding its portfolio of high-tier technologies, TAQA develops a high-performance perforation-plugging patented product.

-

Enhancement to the drillship comes ahead of work commitment on Shell's Sparta development in the US Gulf of Mexico, its first in the Gulf to produce from 20K reservoirs.

-

Derived from the principles of radial jet drilling, a new technology called micro-turbine drilling is developed to allow for drilling of micro-sidetracks from cased boreholes in very hard reservoir rock.

-

This paper details a gravel packing operation in the Martin Linge field in the North Sea that marks the highest density carrier fluid openhole gravel pack completed successfully worldwide, setting a new standard for well completions in challenging high-pressure environments.