Drilling

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

-

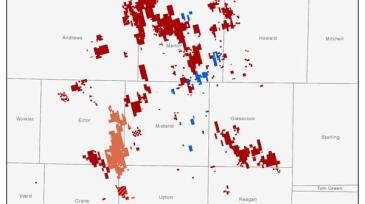

The Permian Basin operator said the purchase ‘checks all the boxes’ it looks for in an acquisition.

-

Seven facilities design and public engagement principles are identified as key elements for the future oil and natural gas production facilities for the DJ Basin, and maybe even as a guide for other North American onshore shale basins.

-

The deal upon closing at year-end would expand Marathon’s position in the south Texas shale play by 130,000 net acres.

-

Remote operations and automation have reshaped the drilling landscape in recent years, but this may be just the beginning. Find out here which big milestones may be coming up next for the drilling sector.

-

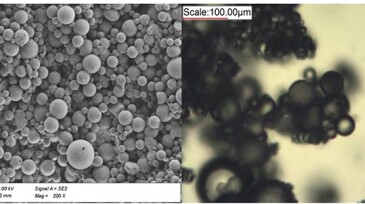

In this paper, β-cyclodextrin polymer microspheres, generally used for drug release and wastewater treatment, are evaluated as an environmentally friendly ultrahigh-temperature filtration reducer.

-

This paper describes the qualification and first deepwater drilling application of a novel aqueous reservoir drilling fluid at temperatures greater than 320°F.

-

Significant reserves additions may be realized if the risks associated with drilling in such harsh conditions can be managed effectively. Design and development of a new generation of drilling fluids able to fulfill all of the attributed functions under extreme pressure and temperature conditions is one of the key requirements for unlocking these resources.

-

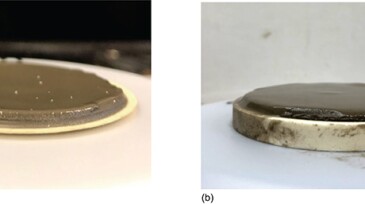

This paper describes a high-density high-pressure/high-temperature brine-based drilling fluid that provides long-term stability and solids-suspension properties for extended periods of time.

-

A leaner and wiser Weatherford seeks new Middle East contracts while growing margins and market share on existing business.

-

ADNOC is hiring more jackup drilling rigs to boost offshore production of its more carbon-friendly brand of crude.