Drilling

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

This study evaluates the feasibility of drilling a closed-loop, unconventional geothermal system in the Pannonian Basin basement of Romania.

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

-

ADNOC Drilling and ADNOC Logistics & Services have won the newest round of contracts to develop the mega sour-gas project that will expand the UAE’s production of LNG.

-

It has often been considered risky to use heavy drillships in depths below 2,000 ft. However, a good measure of innovation and market timing has recently proved otherwise.

-

Industry experts from Fugro analyze what the future holds for offshore energy fields and how the industry can embrace and prepare itself for an autonomous and digital future.

-

The drilling of wells in shale and granite shares a common need—faster drilling is required to make it work.

-

A new report shows that the tight offshore rig market is even tighter than most estimates reflect. This offers relief to battered drilling contractors which are now demanding higher dayrates.

-

H&P pumps $33 million into LNG firm Galileo Technologies, supporting technology focused on decarbonization of the energy supply chain.

-

Technology continues to transform every aspect of our lives and its role in modernizing oilfield operations is no different.

-

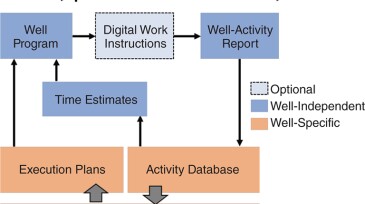

An operator has redefined onsite operations reporting through the development of a standardized set of reporting activity codes as the backbone of a standardized digital well-design and execution process.

-

The authors describe a study analyzing a comprehensive data set recorded in casing-cemented sandwich sections and recovered during the abandonment of a well in the Valhall Field.

-

The paper describes the experience of using a machine-learning model prepared by the ensemble method to prevent stuck-pipe events during well construction in extended-reach wells.