Drilling

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

-

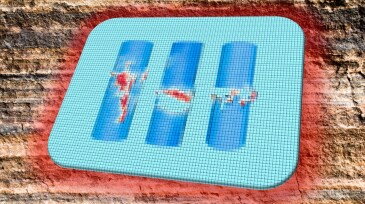

Offline cementing was used to develop a marginal field in Malaysia. The development was made possible through distinctive wellhead technology and good operational planning.

-

Whether considering the customization of drilling approaches in Middle Eastern carbonate reservoirs, implementing a collaborative work flow in tackling high-tortuosity wells offshore Western Australia, or researching the ability of a fibrous material to effect hole cleaning as opposed to polymeric sweeps, the authors of these papers understand that technical expertise…

-

Effective use of downhole dynamics and mechanical specific energy data played a critical role in delivering a well that was the longest in the Middle East, and the fourth-longest globally, at the time of writing.

-

This paper describes the path to implementation of full casing rotation during primary cementing jobs.

-

A specialized fibrous material was examined and was found to be effective for hole-cleaning applications.

-

This paper describes the path to implementation of full casing rotation during primary cementing jobs.

-

Fluid identification, a critical process in fluid sampling, continues to be a challenge in temperatures above 350°F. At temperatures up to 450°F, fluid identification is currently achieved by bubblepoint and compressibility measurements, which cannot quantitatively measure contamination levels of the sample fluid. A possible solution involves using pyroelectric detect…

-

The operator drilled a pair of complex, ultraextended-reach-drilling (ERD) wells a mature offshore Western Australia field despite shallow reservoir depth, extreme ERD profile, and high tortuosity requirements.

-

This year, in the presence of enormous challenges, the selected papers demonstrate step changes both in efficiency and in the results of cementing operations.

-

Shale producers have learned in recent years that their fracture plugs may not be holding up as well as they thought. One of the first operators to realize the true scope of the issue is now sharing the pathway it took to solving it.