Drilling

The Granat prospect on the Norwegian Continental Shelf may be developed with a subsea tieback to existing infrastructure.

Eni reports its latest deepwater exploration well offshore Côte d'Ivoire found gas and condensate in high-quality Cenomanian sands in the Calao channel complex.

Autonomous drilling through managed pressure drilling (MPD) at the Atlantis field has given the operator confidence to scale the method.

-

Fluid identification, a critical process in fluid sampling, continues to be a challenge in temperatures above 350°F. At temperatures up to 450°F, fluid identification is currently achieved by bubblepoint and compressibility measurements, which cannot quantitatively measure contamination levels of the sample fluid. A possible solution involves using pyroelectric detect…

-

The operator drilled a pair of complex, ultraextended-reach-drilling (ERD) wells a mature offshore Western Australia field despite shallow reservoir depth, extreme ERD profile, and high tortuosity requirements.

-

This year, in the presence of enormous challenges, the selected papers demonstrate step changes both in efficiency and in the results of cementing operations.

-

Shale producers have learned in recent years that their fracture plugs may not be holding up as well as they thought. One of the first operators to realize the true scope of the issue is now sharing the pathway it took to solving it.

-

Anomalies in heart function can be diagnosed in real time by measuring an electrical signal. Petroleum engineers have adapted the concept to diagnose anomalous drilling conditions in real time using a shock signature recorded downhole.

-

Schlumberger has won a $480-million contract to drill 96 oil wells in southern Iraq for the country’s Basra Oil Company and for ExxonMobil, which operates the giant West Qurna-1 field with partners from Iraq, Japan, Indonesia, and China. West Qurna-1 is one of the world’s largest oil fields.

-

As the saying goes, the future is now. This is certainly the case offshore Norway, which represents one of the industry’s most influential test beds for impactful innovation.

-

Another technology developer is trying to convince oil companies that they really do need more power and downhole data while drilling.

-

The rig will drill an extended-reach well in the P9 Horizon field.

-

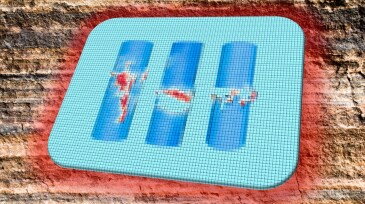

Laboratory formation damage testing is often used to help select optimal drilling and completion fluids, but predicting the overall effect of formation damage on well performance requires further interpretation. Paper SPE 199268 presents a case for use of CFD to upscale laboratory data to quantify that effect.