Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

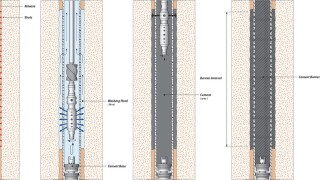

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

This paper describes a new approach to evaluating the effectiveness of the rotary-steerable-system (RSS) steering mechanism on wellbore tortuosity in horizontal wells.

-

The shift toward lower prices in the industry has resulted in the necessity for more wells to be drilled at lower cost. Numerous other industries have shown that they are able to constantly reduce cost per unit. Where do we stand today and what will the future possibly look like?

-

With the arrival and development of rotary steerable systems in the late 1990s, the industry thought that drilling a perfectly smooth and controlled trajectory would not be an issue. Two decades later, we’re still talking about wellbore quality, especially with long and complex horizontal wells.

-

The use of organophilic clays as additives to provide proper rheological and filtration properties in nonaqueous drilling fluids (NADFs) has long been a topic of study. This paper introduced a modified rectorite designed for biodiesel-based drilling fluid (BBDF).

-

The reservoir section of a gas field offshore Sarawak, Malaysia, consists of two massive pinnacle carbonate structures with heterogeneous porosity and permeability and many vugs and faults.

-

Organophilic clays mixed in oil-based drilling fluids (OBDFs) do not exhibit the same viscosity or suspension characteristics as they do in water-based drilling fluids. A new mineral-oil-based drilling fluid (MOBDF) was created by replacing the conventional organophilic clay with a novel polymer.

-

It is no secret that drilling fluid is crucial in drilling operations. The main function of drilling fluids is to transport drill cuttings from the bottom of the hole up to the surface. Drill cuttings then will be separated on the surface before being recycled back for further drilling.

-

With drilling on the rise, US oil production is expected to continue to increase. However, many industry professionals are concerned that the “brute force” model, which has seen a massive influx of capital flow into completion and hydraulic fracturing operations, is not economically sustainable.

-

The union marks the first time an international company has taken a direct equity stake in one of ADNOC’s service companies. BHGE will expand its presence in UAE, while ADNOC will gain access to BHGE technological expertise and proprietary equipment.

-

A new detection and alerting methodology, validated on more than 100 North America onshore wells, blends well information and real-time data to determine a probabilistic belief system. An operator used the system to detect, predict, and alert rig crews to washouts and pump failures.