Drilling

The Granat prospect on the Norwegian Continental Shelf may be developed with a subsea tieback to existing infrastructure.

Eni reports its latest deepwater exploration well offshore Côte d'Ivoire found gas and condensate in high-quality Cenomanian sands in the Calao channel complex.

Autonomous drilling through managed pressure drilling (MPD) at the Atlantis field has given the operator confidence to scale the method.

-

The laboratory will be used primarily to test the sulfide stress cracking resistance of carbon steel alloys for oil wells and offshore drilling applications.

-

This paper discusses the successful application of managed-pressure drilling (MPD) in the basin with reduction in risks and well costs.

-

This paper describes the drilling of high-pressure/high-temperature (HP/HT) deepwater wells through an ultranarrow pore-pressure fracture gradient (PPFG) window by means of technology application and strict procedural control.

-

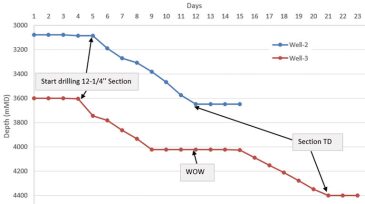

This paper discusses how managed-pressure-drilling (MPD) technology led to cost savings in two wells drilled in the Hai Thach gas field offshore southern Vietnam.

-

Noble’s first row of wells in its massive Mustang project is helping increase the operator’s DJ Basin output, and similar results are soon expected in the Delaware Basin.

-

The contract is helping to solidify Europe’s offshore sector as the focal point for the rise of automated drilling technology.

-

Examples of evolution in well construction during the past several years include new horizontal-well applications, breakthroughs in bit and directional-drilling technology, synthetic fluids, fracture-stimulation advancements, managed-pressure drilling, and the digital revolution.

-

Time spent on bottom drilling is only approximately 10% of the time consumed by drilling operations, but this still provides a significant opportunity for savings if it can be reduced.

-

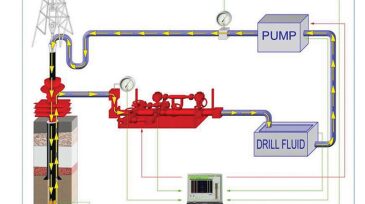

Drilling systems automation requires a digital backbone. One segment of that backbone is the interval between the drill bit and the surface. Wired pipe removes both the bandwidth and latency barriers of the available measurement-while-drilling telemetry systems.

-

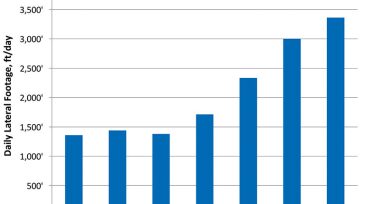

A drilling team has focused on increasing lateral lengths in the Marcellus Shale. The team determined which operational practices would need to be revised in order to drill and case laterals in excess of 18,000 ft.