Flow assurance

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

-

This paper analyzes the risk of hydrate formation and blockage, aiming at various gas/liquid flow patterns and considering the phase distribution and interface distribution characteristics of different flow patterns.

-

Wood is Shell’s exclusive partner for Shell’s Smart Choke technology, which suppresses riser-induced slugging.

-

The complete paper describes the generation of additional fundamental solubility data under HP/HT conditions and comparison of the obtained values with several existing models.

-

Approved in October, the Flow Measurement Technical Section will help engage the greater SPE technical community in flow-measurement-related issues and technologies. It will cover the full spectrum of flow measurement, including single-phase and multiphase flow.

-

A newly developed superhydrophobic coating keeps offshore drilling pipes from being clogged by various substances. R&D Magazine recently recognized the coating and the unique process to apply it to pipes as one of the 100 most significant innovations of 2019.

-

The papers presented here, including the additional reading papers on the potential novel applications of subsea tieback technology, focus on developing new analytical tools and new materials while providing safe, cost-effective, and reliable operations for flow assurance.

-

This paper describes a smart management system used for retrieving and evaluating all flow-assurance-related data for more than 700 of the operator’s onshore and offshore wells.

-

This paper describes a material designed to interact specifically with highly corroded and weathered pipe to enable in-place application and refurbishment.

-

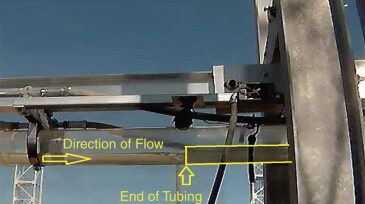

This paper presents the results of an experimental and modeling study that demonstrates the existence of severe slugging in systems with upward-inclined lateral flow paths, such as a toe-down well.

-

Internal corrosion has caused ADNOC to suffer loss of containment in oil flowlines in a giant onshore field. This paper describes the successful 5-year field trial program and confirmation that HDPE liner application in carbon steel pipe can be a cost-efficient way to mitigate internal corrosion.