Flow assurance

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

-

A common hydrate-management strategy involves the use of large volumes of thermodynamic inhibitors (THIs) to operate outside the hydrate-stability region.

-

The complete paper investigates gas-hydrate inhibition in a simulated offshore environment using a plant extract (PE) as a local inhibitor.

-

This paper summarizes historical advancements in low-dosage hydrate inhibitors (LDHIs) over the past 2 decades, discusses their advantages and limitations, and their selection criteria.

-

A new enabling technology known as electrically heat-traced flowline (EHTF) will be used to enable system startup and shutdown and to maintain production fluids outside of the hydrate envelope during steady-state operation.

-

SponsoredParaffins present in crude oil can gel or precipitate, which can cause pipeline and production system blockages. Dow’s ACCENT wax inhibitors are high-active, aqueous-based chemistry, that efficiently control paraffin deposition in pipelines.

-

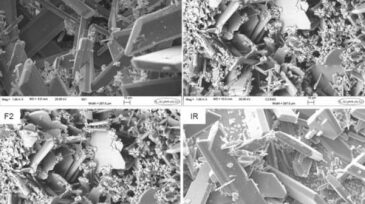

The chemical reactions creating buildups of scale that can clog a well can be replicated in a chemical lab, but researchers are finding many more variables on the surfaces of pipes that need to be considered.

-

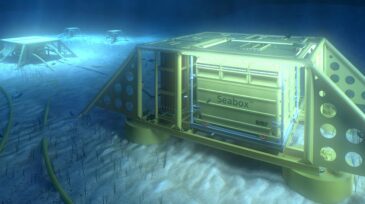

Operators are looking for ways to better handle water coming from subsea wells, which is typically treated at topside facilities. Subsea separation systems are not equipped to discharge water back into the reservoir, so how do companies close the gaps?

-

High-fidelity 3D engineering simulations are valuable in making decisions, but they can be cost-prohibitive and require significant amounts of time to execute. The integration of deep-learning neural networks with computational fluid dynamics may help accelerate the simulation process.

-

SponsoredFlow assurance provides value throughout the entire oil and gas production value chain. Ensuring an uninterrupted flow of hydrocarbon fluids from the reservoir to delivery is key for your operation and profitability.

-

Offshore production assurance continues to drive new production technology applications and approaches. The three papers highlighted here focus on developing analytical tools and performing root-cause analyses while providing safe, cost-effective, and reliable operations.