Flow assurance

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

-

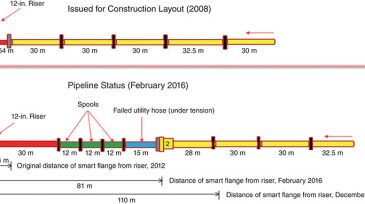

This paper evaluates potential causes of failure for nine pipelines operating in shallow waters (8 to 14 m) in the Gulf of Guinea. The authors develop an analytical method to identify root causes and provide recommendations for pipeline design and placement.

-

Erosion caused by fine solid particles presents one of the greatest threats to oil and gas flow assurance, consequently affecting material selection and wall-thickness design.

-

Comprehension of the mechanisms that influence wax deposition in oil-production systems has not yet been achieved fully. This paper investigates the influence of the Reynolds number on wax deposition.

-

Current logistics and pipeline-infrastructure limitations make transportation and production of waxy crude oil challenging, necessitating a step change in the chemistry required to mitigate crude-oil-composition issues.

-

Banyu Urip crude contains 26% wax, which can lead to flow-assurance challenges in a crude pipeline exposed to lower temperatures. Injection of pour-point-depressant (PPD) chemicals has been considered an effective method to ensure flow of moderate waxy crude.

-

This paper presents a case study that is an example of how reassessing a flow-assurance risk-management strategy for operating assets can identify opportunities for optimization.

-

These balls have the potential to alter how pipeline inspections are done, and a consortium of pipeline operators and industry experts in North Dakota is examining just how well this emerging technology can handle the small-diameter pipelines in the area.

-

Cold finger tests are a standard method for testing paraffin inhibitors, but there is no standard testing protocol, and sometimes different labs can see inconsistent results. Shell and BHGE studied the root causes of these issues.

-

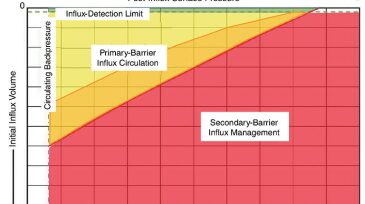

The influx-management-envelope (IME) concept is an advanced, innovative way to assess influx conditions in managed-pressure-drilling (MPD) operations, offering an improved tool for the decision-making process.

-

Offshore project execution enhancement ideas are highlighted for debottlenecking, gas-hydrate-induced pipeline vibration, and the design of subsea systems for efficient startup.