Flow assurance

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

-

A computational fluid dynamics model is proposed to analyze the effect of hydrate flow in pipelines using multiphase-flow-modeling techniques. The results will identify the cause of pipeline failure, regions of maximum stress in the pipeline, and plastic deformation of the pipeline.

-

The 9th International Conference on Gas Hydrates featured discussions on key advancements in flow assurance, including the concept of risk management and anti-agglomerates being applicable strategies in transient operations.

-

Mitigation of flow-assurance problems continues to drive new production-technology applications and approaches. The three papers highlighted here focus on minimizing costs while providing safe, effective, and reliable operations.

-

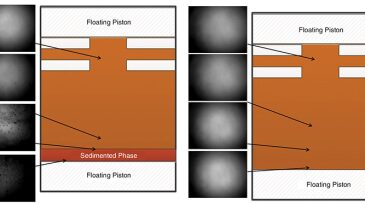

In this study, the effects of the hydrodynamic parameters are decoupled with specially designed flow-loop experiments. The results enhance understanding of the deposition behavior at various hydrodynamic conditions and aid in scaling up from laboratory to field conditions.

-

In this study, two coatings were produced and evaluated to determine their effect on hydrate adhesion onto carbon-steel surfaces.

-

This paper presents the traditional methods of hydrate mitigation used in the NKJ fields and the way in which a transient model was initially built and continuously improved.

-

A BP flow assurance manager explains a methodology for determining and mitigating flow assurance risks.

-

Fluid Efficiency and Rhapsody Venture will partner to refine and launch a new molecular technology to improve the flow in pipelines.

-

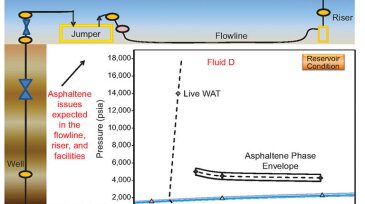

This paper presents an integrated approach to evaluate the key elements of asphaltene risk for deepwater projects, the strategy to manage the issues during production implementation, and aspects to be considered in the mitigation of asphaltene in the field-development plan.

-

This paper presents a methodology that begins by determining the ADE in the laboratory. Moreover, asphaltene-deposition rates for the tubing conditions can be measured using high-pressure/high-temperature coaxial-cylinder technology.