Fracturing/pressure pumping

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

This work demonstrates that a carefully engineered wireline perforation strategy can address the challenges of long-interval high-pressure/high-temperature completions with large intrareservoir-pressure differentials safely and effectively.

This paper describes modeling work performed to design fracturing treatment and spacing for wells in the Project Cape enhanced geothermal system in Utah.

-

Friction reducers play multiple critical roles in fracturing. A challenge in selecting the best one for the job is the growing evidence that performance varies, but objective performance measurements are lacking.

-

Electric-powered fracturing fleets looked impressively resilient in 2020 amid what was otherwise a significant collapse for the hydraulic fracturing sector. Today, the situation is more complicated.

-

Using electricity to run oilfield operations is supposed to make everything better, but just getting the power needed is a challenge.

-

The obsession with better hydraulic fracturing has steadily pushed on shale production in year one, but the decline remains steep. Chemistry could help explain, and perhaps extend, the short productive life of these wells.

-

SponsoredExtended reach wells provide access to otherwise inaccessible areas, improve production and reduce footprint. Advancements in completion technology allow producers to eliminate coiled tubing, perforation guns and milling out operations to lower project risks, costs, and environmental impact.

-

Incremental gains are not always celebrated, but as two of the biggest oil producers in the US show, they nonetheless can net unrealized savings and new efficiencies.

-

The combined company will have a strengthened position in the Permian Basin, and plans to operate 17 hydraulic fracturing fleets in the region.

-

SponsoredAmong the industry’s shortest and most advanced dissolvable frac plugs, Stinger delivered big to this Howard County, TX operator with time and cost savings.

-

SponsoredAmong the industry’s shortest and most advanced dissolvable frac plugs, Stinger delivered big to this Howard County, TX operator with time and cost savings.

-

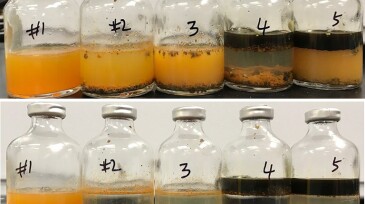

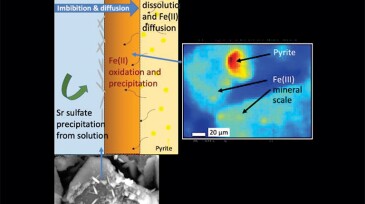

A 2-year study of a formation used for saltwater disposal in the Bakken may hold promise of decreasing the pressurization of the formation and increasing the reuse of the briny produced water.