Fracturing/pressure pumping

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

Oman is embarking on a renewed effort to deploy the latest hydraulic fracturing technologies and techniques, tailored to its unique reservoirs and challenges.

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

-

This article addresses a means to improve hydraulic fracturing operations by measuring the perforation effectiveness on a stage-by-stage basis before the hydraulic fracturing process begins.

-

Unconventional producers around the world have been hamstrung by expensive and cumbersome options when it comes to obtaining reservoir data. Among the latest ways to break past these barriers is a new method developed by Canadian researchers and field tested in Australia’s unconventional frontier.

-

Schlumberger is getting rid of its struggling OneStim business unit 2 years after an acquisition that doubled its size. It will get 37% of the shares of Liberty Oilfield Services, which said it will be the second-largest player in that sector.

-

ExxonMobil is reluctant to join other big oil companies writing down the value of their reserves. It could chop its reserves by 20%, but it has not made a final decision.

-

The forces of low oil prices and new efficiency trends are converging to remake the US pressure-pumping business into one that can complete more wells with less horsepower than ever. However, that might also mean service provider margins remain low for much of this new decade.

-

The investment group Wilks Brothers, now owners of Carbo Ceramics, has sought stakes in other OFS companies this year.

-

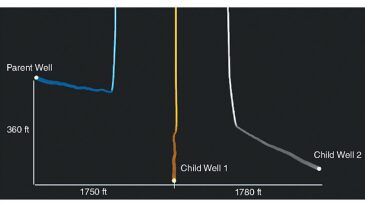

Why stimulate horizontal wells one by one when they can be done two at a time? The largest pressure-pumping company in the business says it might even be possible to complete three wells at once.

-

The contraction of the shale sector and its operations such as drilling and completions due to COVID-19 and the drop in oil price has sifted down to the frac sand suppliers.

-

In an era where capital markets are hitting the brakes on funding the US shale sector, operators have increasingly pivoted from production growth to maximizing the rates of return via lower-cost wells.

-

Carbon dioxide (CO2) waterless fracturing uses liquid CO2 to replace water as the fracturing fluid in reservoir stimulation. The continuity and reliability of the blender are key factors determining performance of the operation.