Fracturing/pressure pumping

This work proposes a method to interpret far-field strain-change and pressure data to quantify fracture connectivity and properties at the cluster level.

Modern completions often are equipped with downhole measurement devices that provide critical real-time data not only during the hydraulic fracturing treatment but also during the ensuing production phase.

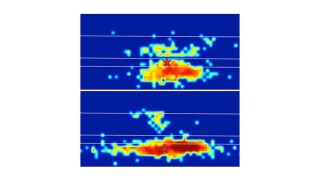

In this work, microseismic observations are integrated with strain and other observations to investigate the microseismic response in relation to the underlying hydraulic fracture geometry for different rock types.

-

Expected to close 31 October, the deal will create one of the largest pressure pumpers in the US.

-

In 2016, the EPA published the findings of a multiyear study, “Hydraulic Fracturing for Oil and Gas: Impacts From the Hydraulic Fracturing Water Cycle on Drinking Water Resources in the United States.” This paper provides a summary of the study’s processes and highlights key finding and limitations.

-

The types of advancements made in real-time drilling data acquisition and processing are now on the doorstep of the North American completions sector. Technology developers are banding together under the umbrella of “coopetition” in a bid to change the way producers fracture tight reservoirs.

-

Not all friction reducers are created equal. With dozens of varieties on the market, industry research suggests that oil and gas companies be choosy.

-

Average production from Bakken wells completed more than 3 years after they were drilled was approximately equal to wells drilled a year before they were put into service, according to a study by the US Energy Information Administration.

-

If you can see it, then maybe you can control it. This sums up the latest quest that the unconventional engineering community embarked upon to get a better understanding of proper well spacing and how fractures really interact.

-

This paper presents a data set involving the pumping of multiple, unique chemical tracers into a single Wolfcamp B fracture stage.

-

The shale sector is studying the results of a 23-well experiment in the southeastern corner of New Mexico to learn what the wider implications might be.

-

A fracturing test site in West Virginia has quietly made a data trove available on the website of the Marcellus Shale Energy and Environment Lab.

-

Pressure pumping equipment has been one of the most neglected areas of technological advancement. This has started to change as innovative developers push out new technologies that are slowly modernizing fracturing fleets, delivering major fuel savings, and creating other tangible efficiencies.