Fracturing/pressure pumping

Major increases in hydrocarbon production require both incremental and revolutionary technologies, industry leaders said during the SPE Hydraulic Fracturing Technology Conference.

Technology developers expect the tight-oil industry to give lightweight proppants another look after the Permian Basin’s biggest operator becomes an adopter.

In this third work in a series, the authors conduct transfer-learning validation with a robust real-field data set for hydraulic fracturing design.

-

Recent studies have found that the viscosities of borate gels at actual downhole pressure conditions may be 80% less than those from standard high-pressure/high-temperature rheometer measurement (which uses 400-psi top pressure).

-

This paper examines the chemistry of developing seawater-based fracturing fluids using two types of polymers as gelling agents and compares results to existing fresh-water-based-fracturing-fluid data under different conditions.

-

This paper presents the results of a comprehensive multiphase-flow study that investigated the relationship between the principal stresses and lateral direction in hydraulically fractured horizontal wells.

-

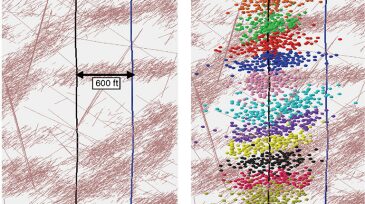

The objective of this study is to validate the concept of using a seismically derived discrete fracture network (DFN) calibrated with borehole measurements, for complex-hydraulic-fracture modeling.

-

Always recorded but almost never used, the water hammer signal could offer completions engineers another set of insightful data if petroleum engineers can crack its code.

-

PDC’s president and CEO describes the company’s management strategy for its hydraulic fracturing operations in the Wattenberg Field and the Delaware Basin.

-

Permian Basin producer Callon Petroleum is attributing its data-driven approach to a routine completions practice to improved proppant placement and higher oil production.

-

Battlecat Oil & Gas ratcheted up on data, analysis, and technology to successfully develop unproven shale acreage.

-

Although Saudi Arabia has plenty of sand, it took some ingenuity by Saudi Aramco and Schlumberger to figure out how to use it effectively as proppant.

-

In the keynote speech at the SPE Hydraulic Fracturing Technology Conference, author and founder of the Center for Industrial Progress Alex Epstein explained the moral case for fossil fuels.