Fracturing/pressure pumping

Major increases in hydrocarbon production require both incremental and revolutionary technologies, industry leaders said during the SPE Hydraulic Fracturing Technology Conference.

Technology developers expect the tight-oil industry to give lightweight proppants another look after the Permian Basin’s biggest operator becomes an adopter.

In this third work in a series, the authors conduct transfer-learning validation with a robust real-field data set for hydraulic fracturing design.

-

US drilling and completion companies that were slashing workforces and cannibalizing pumping trucks for parts 6 months ago are now hiring crews and repairing equipment to meet rising demand.

-

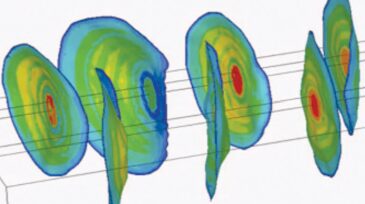

Around the top of the list of ways to make hydraulic fracturing more efficient is by expanding the area that is effectively fractured. There is growing evidence of the need for methods to do this that are cost-effective, reliable, and repeatable in wells that vary widely.

-

The successes and challenges of producers in the United States’ most active oil play received a wide-ranging discussion by three panelists recently at an SPE Gulf Coast Section meeting in Houston on the state of the Permian Basin.

-

One of the oldest names in geomechanical modeling has learned some new tricks, and like so many recent advances in the oil and gas industry, it has everything to do with the North American shale revolution.

-

A new diagnostic technology that exclusively uses surface pressure data to map hydraulic fracturing in unconventional reservoirs has helped an operator to improve well completion designs in its Oklahoma field activities.

-

The US EPA’s 2016 New Source Performance Standards updated the 2012 standards by adding requirements for the industry to reduce greenhouse gas emissions, specifically methane. The 2016 NSPS also covers hydraulically fractured oil wells and production, processing, transmission and storage activities.

-

Geophysicists from Stanford University have compiled a map of new maximum horizontal stress orientations in Texas and surrounding areas, potentially giving operators new information for avoiding seismic activity in their hydraulic fracturing operations.

-

The Wyoming Department of Environmental Quality recently concluded that hydraulic fracturing operations were not the likely cause of well water contamination in a small town.

-

Sourcing water for large multifracture stimulations in west Texas is a well-known constraint on oil and gas activities in the area. A 6-month pilot operation demonstrated that produced-water reuse is technically feasible and can be a cost-effective solution.

-

This paper summarizes the benefits of using a bipolymer crosslinking system in environments where water quality cannot be guaranteed. It also demonstrates the yielded cost savings per well that are achievable when reusing 100% produced or flowback water for hydraulic fracturing.