Fracturing/pressure pumping

Major increases in hydrocarbon production require both incremental and revolutionary technologies, industry leaders said during the SPE Hydraulic Fracturing Technology Conference.

Technology developers expect the tight-oil industry to give lightweight proppants another look after the Permian Basin’s biggest operator becomes an adopter.

In this third work in a series, the authors conduct transfer-learning validation with a robust real-field data set for hydraulic fracturing design.

-

Companies are deploying a variety of technologies to reduce the water needs of hydraulic fracturing. Where are these new facilities with these new technologies, and how will they help operators solve the problem of finding water to use?

-

Over the next few years, water treatment technologies are expected to continue to be deployed in the basin, as drought drives aquifer levels to new lows.

-

Hydraulically fracturing and stimulating multiple horizontal wells in sequence has been rapidly adopted by operators because of the potential for production without introducing unwanted risks.

-

While storage and logistics are critical elements of the viability of water reuse, if the water chemistry is not fit for gel fracturing formulations, it will not matter how much is stored in centrally located impoundments.

-

Evenly fracturing all clusters in heterogeneous zones is challenging in long horizontal sections penetrating heterogeneous reservoirs, as is often the case in the Eagle Ford shale.

-

This paper attempts to describe some of the common problems and to help prevent some common errors often observed in diagnostic fracture injection tests (DFITs) execution and analysis.

-

Refracturing older unconventional wells is likely to reward those willing to investigate the reasons why production declines and what can be done to restore it, according to George King, distinguished engineering adviser at Apache Corp.

-

This paper describes a modeling technique by which hydraulic fractures are represented as part of the well model rather than as any form of refinement in the simulation grid.

-

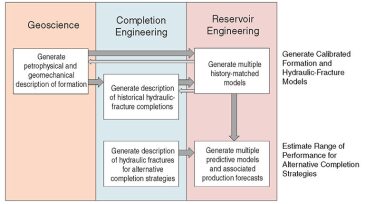

This paper presents a pragmatic integrated work flow used to optimize development and guide critical development decisions in the Black Hawk field.

-

This paper discusses fracture stimulation in the first joint-venture shale-gas project with foreign companies in China.