Fracturing/pressure pumping

Major increases in hydrocarbon production require both incremental and revolutionary technologies, industry leaders said during the SPE Hydraulic Fracturing Technology Conference.

Technology developers expect the tight-oil industry to give lightweight proppants another look after the Permian Basin’s biggest operator becomes an adopter.

In this third work in a series, the authors conduct transfer-learning validation with a robust real-field data set for hydraulic fracturing design.

-

Used extensively by the food, chemical, and pharmaceutical industries, the mechanical-vapor-recompression (MVR) process is viewed as a reliable method for recovering demineralized water from concentrated brines. This paper reports on performance of an advanced MVR system in north-central Texas.

-

A growing chorus of suppliers, researchers, and service companies is persuading US operators to re-examine their use of slickwater in shale plays and consider displacing it with carbon dioxide and nitrogen.

-

Pumping fracturing jobs is an equipment killer. The job requires running enormous quantities of water and sand through a pump, which is an abrasive mix that damages pumps in ways that cannot be fixed. Adding to the pressure is the trend toward clustering wells on pad sites that extend run time.

-

Hydraulic fracturing solutions use a gelling agent known as guar gum to transport proppant. Flowback water can have guar gum concentrations has high as 1% by volume creating treatment challenges prior to reuse or disposal.

-

For those in shale exploration, “fracability” is a real word, a critical property, and a point of contention.

-

With inconsistent inlet water quality being the rule rather than the exception, sizing and operational considerations of the treatment system components must vary accordingly to make the most economic sense.

-

While shale unproved technically recoverable resources have been identified around the world, development has been limited to North America.

-

Some operators are returning to their North American mature unconventional shale wells to refracture, or restimulate, the rock to accelerate production and enhance ultimate recoveries.

-

At the 2014 SPE Hydraulic Fracturing Technology Conference in February, former Texas A&M Department of Petroleum Engineering head Stephen A. Holditch received a well-deserved lifetime achievement recognition, the Legends of Hydraulic Fracturing Award.

-

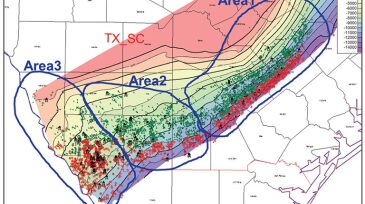

The purpose of this paper is to apply multivariate statistical modeling in conjunction with geographic-information-systems (GIS) pattern-recognition work to the Eagle Ford.