Inspection/maintenance

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

Using autonomous systems creates efficiencies, but, even more critically, it also allows engineers to be engineers.

-

The Saudi Arabian major is finding new ways of using drones to help improve the safety, efficiency, and environmental performance of its operations.

-

The partnership aims to use artificial intelligence and advanced robotics to accelerate the adoption of technologies for predictive maintenance.

-

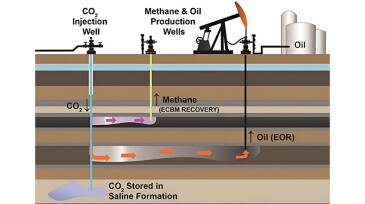

The long, successful history of various metallurgies in EOR wells has been cited as sufficient to allow the same completions for CCS injection wells. The lack of actual data on the long-term performance of these alloys in EOR wells in combination with the more-stringent requirements for Class VI wells suggests otherwise.

-

Specialty forgers manufacture custom, seamless rolled rings in a variety of materials and finishes in as little as 8 weeks.

-

Suncor Energy brought the Terra Nova FPSO back into production as part of an extensive field life extension project offshore Newfoundland and Labrador.

-

The job will increase the Heerema vessel’s second main hoist capacity by 1200 mt.

-

The Haewene Brim FPSO will need repairs to a pair of mooring connections before it can restart operations.

-

The two newest crew members of the Pazflor floating production, storage, and offloading unit are a pair of robots capable of inspecting 1,700 different points of interest.

-

The USV will be equipped with a remotely operated vehicle that is capable of operating in water up to 1500 m deep and tools to perform subsea operations.