Inspection/maintenance

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

The venture will deploy Eni's real-time, pipeline-integrity monitoring system.

-

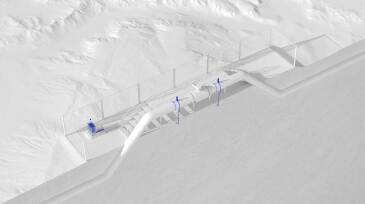

Norway’s USV joint venture will launch its first unmanned offshore surface vessel in 2025 to support subsea inspection, maintenance, and repairs.

-

A new ASTM International standard will help to control microbial contamination that can degrade turbine oils and turbine oil systems. ASTM’s committee on petroleum products, liquid fuels, and lubricants (D02) developed the standard, which will soon be published as D8506.

-

The Swiss-based company Hydromea announced advances in underwater optical modem technology and development of an underwater monitoring system capable of daily data sweeps remotely.

-

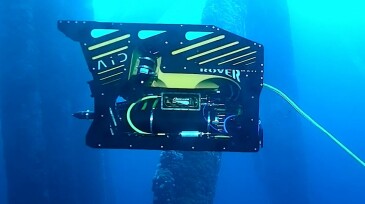

Ocean services provider DeepOcean has mobilized its first autonomous inspection drone and plans to conduct offshore trials for an operator on the Norwegian continental shelf.

-

Paraffin deposition on the meters measuring produced water volumes causes inaccurate readings. New technology solutions enable lasting accuracy in the place of routine maintenance that provides a temporary solution.

-

A high-resolution acoustic downhole evaluation system nabs top award for 2023.

-

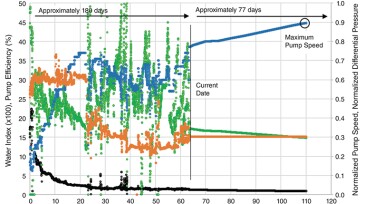

This paper presents a proposed condition indicator that estimates the wear experienced by an all-metal progressing cavity pump at any point in operation and takes into consideration the effects of downhole operating conditions.

-

The company used an uncrewed surface vessel and an electric remotely operated vehicle to conduct a survey for TAQA in the North Sea.

-

The North Sea's largest producing field has shut in about a quarter of its total production capacity as repairs are made to faulty equipment.