Oilfield chemistry

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

The authors of this paper aim to design, optimize, and evaluate a scalable and energy-efficient plasma-driven advanced-oxidative-process system for produced-water remediation, emphasizing regulatory compliance for safe discharge or reuse.

-

The featured papers and suggested further reading summarize the current SPE literature state of the art for H2S scavenger research and development and have been selected to give readers a broad indication from both academia and industry around the world.

-

This paper describes studies that confirm that enzyme-based, environmentally preferable chemistries can be used to break polymers and mitigate H2S in various systems.

-

The source of gummy, damaging polymer gunk that has flowed from Oklahoma oil wells is becoming clear, and one of the lessons learned is that shale plays require petroleum engineers to learn more about chemistry.

-

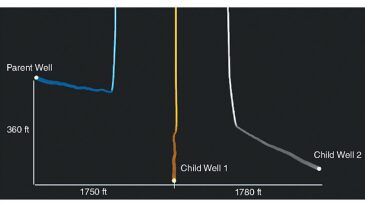

In an era where capital markets are hitting the brakes on funding the US shale sector, operators have increasingly pivoted from production growth to maximizing the rates of return via lower-cost wells.

-

The complete paper highlights examples of nonmetallic materials selection and qualification for upstream water-injection and producer and hydrocarbon wells and presents suggestions for future progress.

-

The complete paper discusses the importance of adequate preparation and the approaches used to overcome challenges of EOR operations, including handling back-produced polymer.

-

Researchers use novel methodology to measure the thermo-electric properties of native crude.

-

Approved in October, the Flow Measurement Technical Section will help engage the greater SPE technical community in flow-measurement-related issues and technologies. It will cover the full spectrum of flow measurement, including single-phase and multiphase flow.

-

DuPont Microbial Control research scientist and “microbial detective” Geert van der Kraan shares the clues that microbial life leaves behind to help make the extraction process cleaner in a recent TED Talk.

-

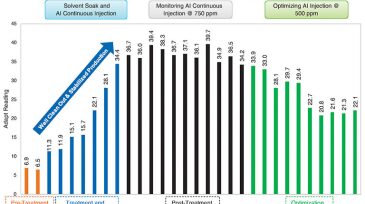

Scaling buildup inside wellbores is a serious production problem that dramatically reduces the well productivity index. This issue has a significant cost across the industry, mostly associated with loss of production or additional operations such as well intervention.