Offshore/subsea systems

The company has installed an autonomous drone system on Aker BP’s Edvard Grieg platform in the North Sea, enabling frequent, remote inspections from shore.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

This paper describes the first riserless coiled tubing services operation performed in a live subsea well and the associated improvements in efficiency, cost savings, and safety.

-

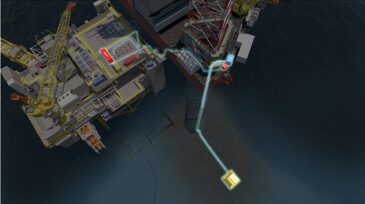

This paper identifies potentially significant hidden value of subsea multiphase boosting technology, or aspects of it that have not received adequate attention during the field-development decision-making process.

-

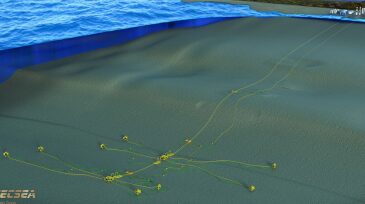

The Dalmatian project is a brownfield development and represents the world’s longest multiphase tieback by boosting at some 35 km; the boosting system is installed at approximately 6,000 ft water depth.

-

The motto of the Olympic Games is “Citius, Altius, Fortius,” Latin for “faster, higher, stronger,” which emphasizes the concept of pushing the limits. As an engineer, that approach really speaks to me—and offshore installations, and especially offshore tiebacks, illustrate that concept very well.

-

Eni conducted a research project to explore the maturity of new technologies to enable economical development of deepwater prospects with tieback distances longer than 50 km and 150 km, respectively, for oil and gas fields.

-

This case study describes how gas condensates within a subsea tieback system behave very differently to condensed water from a wet-gas system and therefore a pseudo dry-gas system needs to be configured differently for gas-condensate developments.

-

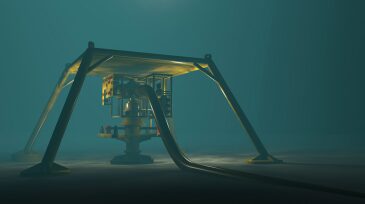

A subsea water-treatment system designed to leverage space availability, steady temperatures, lower bacteria levels, and other natural benefits of the seabed environment was successfully installed during pilot testing at the Ekofisk field offshore Norway.

-

Aimed at streamlining manufacturing processes and significantly reducing costs, the practice provides standardized operator requirements that DNV GL says will ensure consistency in the fabrication of subsea pressure retaining equipment such as wellheads, manifolds, and jumpers.

-

Bloomberg reports that Saipem is seeking to bulk up and weather an industry downturn. A potential deal could create an oilfield service giant with more than $12.4 billion in revenue.

-

Before the dream of a “subsea factory” can come true, a group of North Sea companies will need to see if the required technology is economically feasible to build.

-

Technip Energies will work on a backlog comprising more than 50% in LNG-related business. Retaining the TechnipFMC name, RemainCo will generate nearly 90% of its revenue outside the US and Canada.