Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

Against a backdrop of global uncertainty and challenging economics, well integrity subject-matter experts have continued to prioritize human and environmental safety in production while pivoting their skills toward areas of growing importance such as carbon capture and sequestration. New technologies and simulation methods have allowed the authors of the three SPE pap…

-

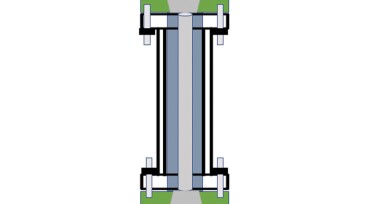

This paper examines current practices and developing trends in well construction and describes an alternative cementless approach to the discipline.

-

SponsoredShell needed an easy-to-use, simple well monitoring solution. Could an IoT wireless solution measure up to a classic wired approach?

-

Hiber, an industrial Internet-of-Things startup, announced that it has signed an agreement with Shell to provide well-integrity monitoring solutions globally.

-

SponsoredWellbore deformation can occur at any stage in the life of a well. Whether a result of changes in temperature, pressure or tectonic forces, wellbore deformation may result in serious downhole issues such as restricted access for interventions or the loss of well integrity that may ultimately lead to premature well abandonment and significantly reduced economic perform…

-

A wellbore repair tool was successfully deployed to rectify collapsed tubing in a remote well off the coast of Papua New Guinea.

-

This paper’s authors describe the development of a coiled tubing (CT) nitrogen-lift design in which CT and geothermal reservoir simulations were combined to overcome modeling limitations.

-

SponsoredWell monitoring hasn’t been easy. But it’s something that has to be done. Remote oil and gas wells are notoriously difficult to monitor. But new technology may make them some of the most advanced sites out there.

-

Contractor renews incident-response partnership for 2 additional years.

-

The average geothermal gradient in the subject deepwater field in Nigeria is 4.37°C/100 m, nearly twice the gradient in most fields. As a result, the magnitude of the expected annular pressure buildup (APB) during steady-state production is large enough to threaten well integrity.