Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

The complete paper discusses a geophone array, including four, three-component geophones deployed by wireline, that provides a solution for this problem by creating a 3D map of the acoustic environment.

-

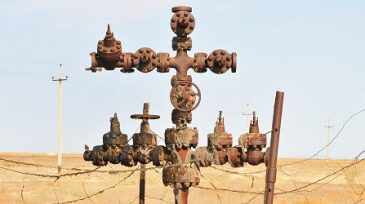

Integrity (noun): the condition of having no part or element wanting; unbroken state; material wholeness, completeness, entirety. While reviewing the abstracts, I was struck by the huge range of challenges to maintaining “material wholeness” beyond the routine testing of tree and safety valves.

-

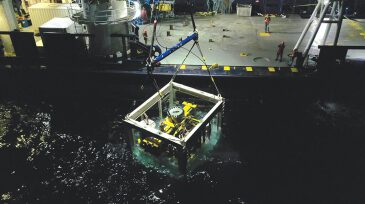

In 2013, a technology-development project began that digitized, automated, and applied analytics to blowout preventer pressure testing. As a result of the deployment of automated BOP testing, significant improvements have been achieved in process safety, personal safety, and rig-time savings.

-

This paper discusses a new, comprehensive cuttings-transport model designed to enable safe and improved hole-cleaning operations.

-

Traditionally, a wellhead system requires a drilling lockdown sleeve (LDS) during drilling operations to ensure that the seal assembly is rigid and prevents dynamic movement. By eliminating the LDS, however, the operator will save multiple trips into the well.

-

An analysis of existing wells in the Martin Linge field, conducted by Equinor when it took over as operator from Total, revealed that several did not have sufficient barriers, leading the company to plan new wells to ensure safe operation.

-

The Alberta government has announced a new liability management framework aimed at expediting the cleanup of orphan and inactive well sites, signaling a more active approach to reclamation and management of those sites.

-

Weatherford will embed INT’s IVAAP framework into the Weatherford Centro digital well delivery software, advancing its data-visualization capabilities.

-

A lot about the blowout preventers used for offshore drilling has changed since Macondo in 2010, but the essentials remain. This evolution serves as a case study on why some oilfield technology is hard to change.

-

The US Chemical Safety Board will investigate the blowout that killed three workers at a Chesapeake Energy well in central Texas.