Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

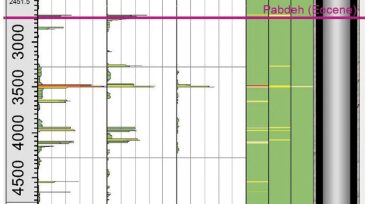

This case study discusses the methodology that underlies the successful determination of the depths and the radial locations in the outer casing strings of multiple leaks in an offshore well.

-

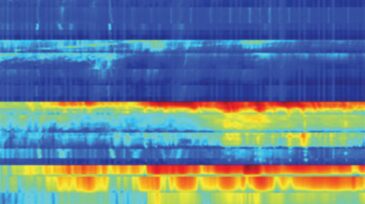

Fiber-optic technologies—distributed temperature sensing and distributed acoustic sensing—have been experiencing an ever-increasing number of applications in the oil and gas industry as monitoring systems.

-

This paper focuses on the preparation for, and implementation of, well-control training, while highlighting the integration of people skills into curricula and what advantages operators and drilling contractors have obtained.

-

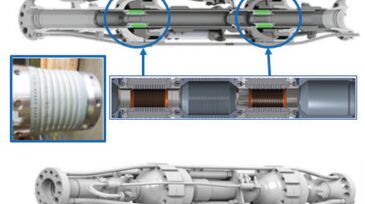

This paper describes the mobilization of a snubbing unit and blowout preventer (BOP) stack in the Middle East that enabled a well with an underground blowout and surface broaching to be brought under control within a short time.

-

Regulators say the blowout that killed five workers on a Patterson-UTI rig in Oklahoma was the product of a slow-moving series of missed signals, misleading testing, and miscalculations that failed to control a natural gas influx.

-

The new well control rule is evidence that memories of the Macondo blowout remain a powerful force for caution. Despite the rhetoric on both sides of this hot-button issue suggesting big changes, the final changes were incremental.

-

Three onshore fields in the Emirate of Sharjah, United Arab Emirates, have more than 30 years of production history from more than 50 gas-condensate wells.

-

This paper describes how a technique known as applied-surface-backpressure managed-pressure drilling (ASBP-MPD) can alleviate the limitations of conventional deepwater well control.

-

Nonaqueous drilling fluids, such as synthetic-based and oil-based mud (SBM and OBM, respectively), are used frequently to drill one or more sections of a well to reduce drilling problems such as shale sloughing, wellbore stability, and stuck pipe.

-

Since the 1980s, many technical works have focused on improving the ability to detect hydrocarbons inside the riser and safely remove them from the system. This trend gained extra momentum with the advent of systems such as riser-gas handlers and managed-pressure drilling.