Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

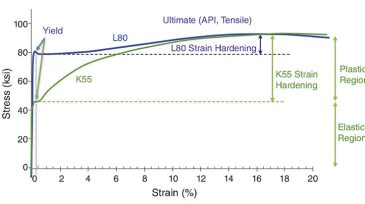

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

A single-well polymer-injection and back-production test has been performed in an oil and gas field offshore Norway. The objective of the test was to verify at field conditions the properties measured in the laboratory for the biopolymer schizophyllan.

-

Wells often end up producing oil and gas far longer than expected. But that often requires the operator to commit to building and maintaining facilities for the long haul.

-

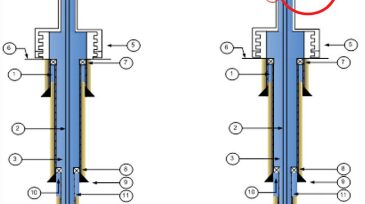

Nonaqueous drilling fluids have been used extensively by the industry, particularly in complex drilling scenarios. They carry some concerns, however, with implications for well integrity.

-

Managed-pressure drilling (MPD) challenges the conventional drilling paradigm, along with drilling-contractor and operator policies and standards. Conventional drilling practices for connections, flow checks, tripping, and well control have been long understood and standardized.

-

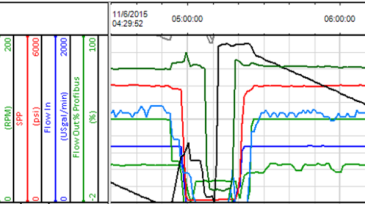

In this study, pressure-while-drilling technologies are combined with software simulations to differentiate drilling-fluid thermal expansion, wellbore ballooning, and formation influx during riserless drilling operations.

-

Thermal-well operations come with significant additional complexity in regard to maintaining wellbore integrity and hydraulic isolation from other formations.

-

Exception-based monitoring of real-time data by remote operators can increase operational awareness of drilling crews, which can significantly minimize well-control risks by taking proactive and precise actions.

-

This 1-day interactive workshop will examine completion/workover/intervention well-control incidents and explore closely a number of key aspects, including what human factors played a part in the well-control incident.

-

Many of the worst oilfield incidents have been attributable to human factors. Consequently, a corporate well-control manual was refreshed to include human factors in the management of well-control incidents.

-

New long-term contracts between offshore drillers and equipment makers reduce downtime and risks associated with key components, from blowout preventers to risers.