Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

The unique properties of deepwater formations pose significant challenges to the capabilities of conventional drilling rigs. Using automated drilling equipment, including MPD, efficiency and cost savings can accompany safety.

-

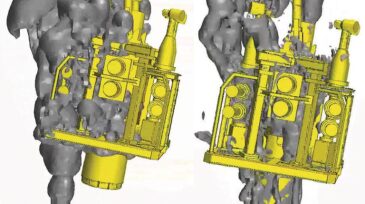

Developing a well-specific subsea-capping contingency plan involves assessing the feasibility of deploying a capping stack from a floating vessel, determining the weight and stability, and performing dynamic-flow simulations of closing the capping stack outlets.

-

One of the more important aspects of well integrity during drilling operations is early kick detection. Recently, new technologies and re-search have been applied or developed to improve the kick-detection systems and to overcome some of the difficulties.

-

A study using a dynamic multiphase-flow software simulated a rapid-unloading event and determined the gas fraction in the riser annulus and the effect on riser fluid levels.

-

An influx-detection-at-pumps-stop (IDAPS) software was developed to provide early warning of abnormal flowback conditions during connections.

-

This paper presents a new technology and methods that can detect leak locations in a well and illustrate the flow profile of the leak.

-

The engineering and operational planning to ensure that no uncontrolled hydrocarbon releases occur during the execution of subsea big-bore gas wells are described.

-

Well control is built around huge steel machines, but the future of the business is digital. Data have become a critical asset as operators and service companies work to increase the safety and reliability of their products and operations.

-

A new blowout preventer design shows potential for delivering much greater shearing power than current BOPs. The design is simpler and more efficient than current BOPs.

-

Precise casing-wear prediction is important for improving well integrity and longevity, while simultaneously making casing designs more cost-effective. There are no industry guidelines for casing-wear prediction. This article presents a validated predictive model.