Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

This paper describes experiences, challenges, and approaches to solving the problems related to creating an advanced early kick-detection system suitable for floating mobile offshore drilling units.

-

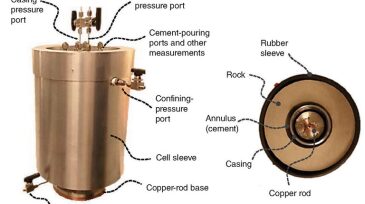

Operators in the North Sea have been concerned about the ability of the cement sheath to maintain sealing integrity because of the increasing number of reported failures in mature wells. This paper presents results from a new laboratory setup to visualize the source of issues.

-

The tragic blowout of Macondo has triggered many technical and managerial developments in the field of well integrity.

-

The North field offshore Qatar was observed to have a chance of inner annuli becoming charged with shallow-gas pressure with possible communication to other annuli, which was thought to be a well integrity concern.

-

Despite multitier safeguards, blowouts occur. When such accidents happen, rate estimation is an important and daunting task.

-

Australian technology developer MezurX is touting its newly introduced flow, density, and mud monitoring system as a significantly better alternative to the widely used Coriolis meter.

-

On the basis of safety performance results achieved through automation downstream, an operator set out to achieve the same advances in its upstream business.

-

As deeper and more complex well designs proliferate throughout oil and gas fields, well completion methods are challenged and new technologies are emerging to ensure safe, cost-efficient, and optimized completions.

-

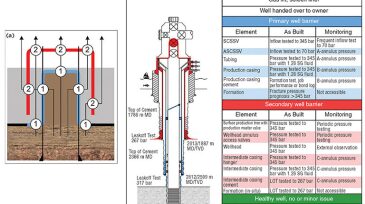

Well integrity and well barriers have been part of the exploitation for oil and gas for nearly a century, with the introduction of the blowout preventer (BOP) in the 1920s.

-

Well control training programs for deepwater drillers and key rig personnel are undergoing a major overhaul that has been years in the making.