Carbon capture and storage (CCS) is a pivotal technology for mitigating carbon dioxide (CO2) emissions and reaching the net-zero targets. As pressure ramps up to meet net-zero targets, there’s a growing push to scale up CCS at an unprecedented pace. According to the International Energy Agency (IEA), global CCS capacity is set to increase dramatically by 2030.

The IEA notes that if all announced CCS projects come to fruition, the world’s CO2 capture capacity would expand from roughly 45 mtpa to nearly 400 mtpa in 2030 (IEA, 2023). The IEA also notes that, according to the current project pipeline, dedicated CO₂ storage capacity may reach up to 615 mtpa by 2030, exceeding the presently planned capture capacity.

Hence, it is vital to ensure that CO₂ can be injected and contained safely over long timescales. Reservoir management in CCS encompasses the technical and geological aspects of selecting a suitable site, thoroughly characterizing the subsurface, modeling and planning injection operations, monitoring the CO₂ plume, and ensuring long-term containment.

For CO₂ to be stored at industrial rates, the injection site must demonstrate a capacity to accept this CO₂ at high rates within the project timelines. This is called the reservoir injectivity and it is determined by the reservoir’s intrinsic permeability and connectivity, often verified through well tests and core analyses (Alcalde et al., 2021).

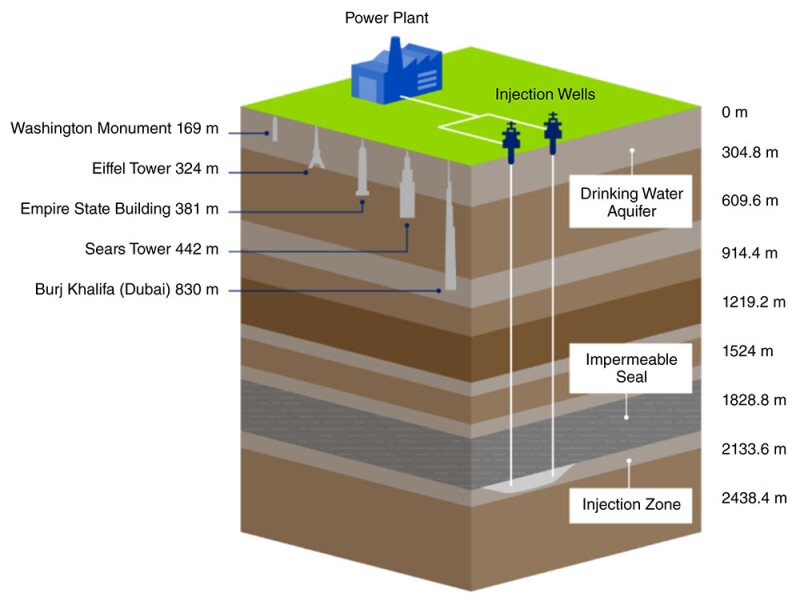

Moreover, for CO₂ to remain in a supercritical state (which dramatically increases storage capacity as it occupies smaller volume of the rock), reservoirs are generally required to be deeper than 800 m (Fig. 1). The high pressure and temperature at these depths ensure that CO₂ acts more like a fluid than a gas, which is critical for maximizing storage efficiency (IEAGHG, 2010).

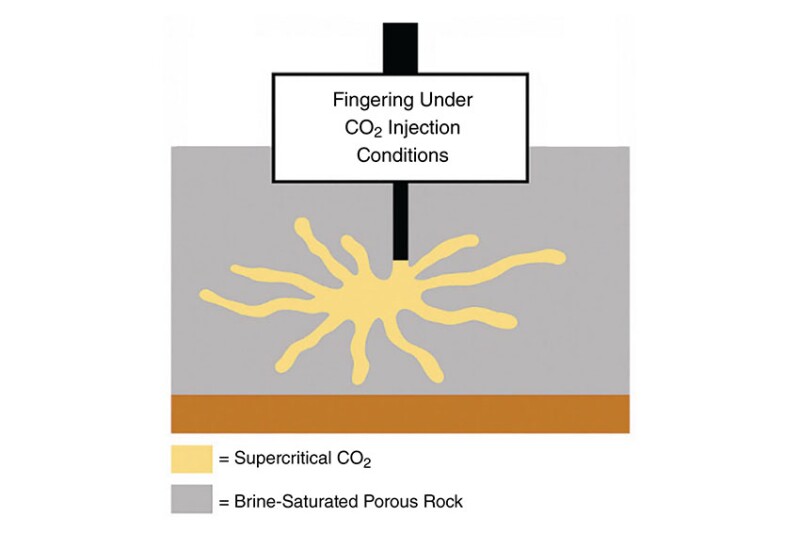

On the other hand, supercritical CO₂ is much less viscous than the resident brine, and it is also buoyant (i.e., lower density) relative to brine. This combination (i.e., low viscosity and buoyancy) means the CO₂ tends to race through the most permeable pathways and override toward the top of the reservoir under gravity, instead of uniformly sweeping the whole rock volume. The result can be fingering and channeling of CO₂, leaving significant pockets of the reservoir untouched by the CO₂ plume (Fig. 2).

In practical terms, inefficient sweep implies lower storage utilization—a smaller fraction of the pore space gets filled with CO₂—and, in enhanced oil recovery (EOR) settings, poorer oil displacement (Nazarian et al., 2013; Flett et al., 2007; Hassanzadeh et al., 2009).

Techniques for Better Sweep Performance

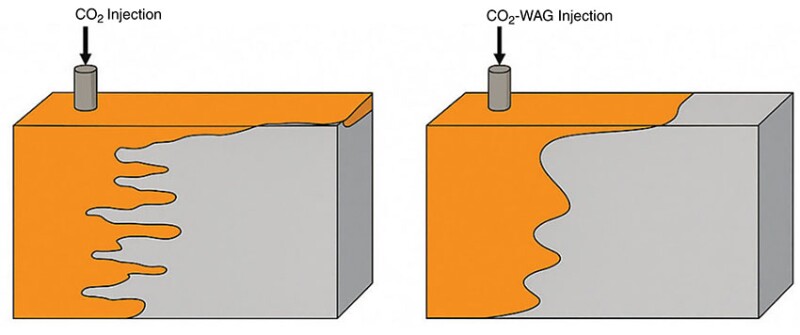

To improve sweep, reservoir engineers look to techniques developed in EOR. One common method is water-alternating-gas (WAG) injection, where water and CO₂ are injected in alternating slugs. The water increases the overall fluid viscosity and helps control the CO₂ mobility, forcing CO₂ into zones it would otherwise bypass (Christensen et al., 2001). WAG has been shown to reduce viscous fingering and yield more uniform CO₂ distribution in EOR projects, and conceptually the same approach can improve CO₂ coverage in a storage formation (Fig. 3).

Another approach is simply to use more injection wells spread across the reservoir to inject CO₂ at multiple points—this can increase areal sweep, though at a higher cost. Heterogeneity in rock permeability, porosity, and capillary pressure are all major factors as well (Darraj, et al., 2024). If the formation has layers, or baffles, the CO₂ may get held up in high-permeability streaks. In such cases, adjusting injection rates or patterns between wells may help coax the CO₂ into lower-permeability regions.

Overall, maximizing sweep efficiency is important for both effective use of the storage capacity and for ensuring the CO₂ plume does not concentrate in one place (which could increase local pressure). Reservoir modeling and monitoring (e.g., observing plume movement via seismic surveys) are used to understand the plume distribution and adjust the injection strategy if needed.

Another strategy is composition swing injection (CSI). CSI is an innovative strategy that involves alternately injecting CO₂ streams with slightly different compositions, resulting in periodic changes in fluid density and viscosity. This composition tuning helps manage plume mobility, reduce gravity-driven override to prevent rapid segregation, and improve sweep efficiency.

By limiting the rapid upward migration of CO₂ and promoting more uniform lateral spread, CSI enhances the storage efficiency and security of the reservoir. Additionally, the modified injection scheme can increase the extent of residual and solubility trapping, both of which are essential mechanisms for long-term containment of CO₂ in subsurface formations (Nazarian, et al., 2014).

However, the approach demands careful design and operational oversight, particularly in terms of injection scheduling and reservoir characterization, to ensure that the altered plume behavior aligns with the geomechanical and geochemical constraints of the storage site (Kulkarni, et al., 2006; Nazarian, et al., 2014). It is important to point out that this technique mirrors established principles from petroleum engineering, where compositional flooding has been shown to increase sweep efficiency in miscible gas injections (Lake et al., 2014).

Other techniques include temperature swing injection (TSI) and pressure swing injection (PSI).

TSI involves varying the temperature of injected CO₂ to influence its interaction with the reservoir. Injecting cooler CO₂ into a warmer reservoir can induce thermal stresses, potentially enhancing fracture propagation and improving injectivity. However, this approach requires careful management to prevent unintended fracturing that could compromise storage integrity.

Recent studies have explored the optimization of TSI by balancing injection temperatures to maximize storage while minimizing risks. For instance, injecting CO₂ at temperatures significantly lower than the reservoir's can lead to increased fracture lengths but may also reduce the overall storage capacity if not properly managed.

On the other hand, PSI involves alternating the injection pressure of CO₂ to enhance storage efficiency. By varying pressures, PSI can improve the distribution of CO₂ within the reservoir, promoting better contact with the rock matrix and enhancing trapping mechanisms. This method can also help in managing reservoir pressures to avoid exceeding fracture gradients, thereby maintaining caprock integrity. While PSI offers potential benefits, its implementation requires precise control and monitoring. Fluctuating pressures can lead to complex reservoir behaviors, and without careful management, there's a risk of inducing fractures or compromising the seal integrity.

Impact of Well Construction and Design

While active plume control techniques focus on the fluid behavior, another equally critical aspect is the physical delivery system. This is why it is fair to say that well architecture can become either a bottleneck or a breakthrough.

In heterogeneous reservoirs, a single vertical injection well can lead to uneven CO₂ distribution and rapid pressure buildup. The injected CO₂ preferentially enters the most-permeable layers while bypassing lower-permeability strata. As buoyant CO₂ rises within the formation, flow concentrates in the upper high-transmissivity zones, underutilizing large portions of the reservoir. This behavior reduces storage efficiency and can hasten the upward spread of the plume (analogous to an early breakthrough toward the caprock or boundaries).

Consequently, vertical injectors may encounter rising wellbore pressures. At the Snøhvit CCS project in Norway, for example, injection into the fluvial Tubåen Formation had to be suspended (after only about 3 years and almost 1.1 Mt of CO₂ injected) because reservoir pressure approached the caprock fracture threshold.

This prompted a well workover in 2011 to recomplete the injector in a higher-permeability formation, relieving the excessive pressure. Notably, the Sleipner field’s CO₂ is not injected via a truly vertical well as sometimes assumed. Instead, Sleipner utilizes a long-reach near-horizontal well, which has achieved stable injection with minimal pressure buildup for more than 2 decades.

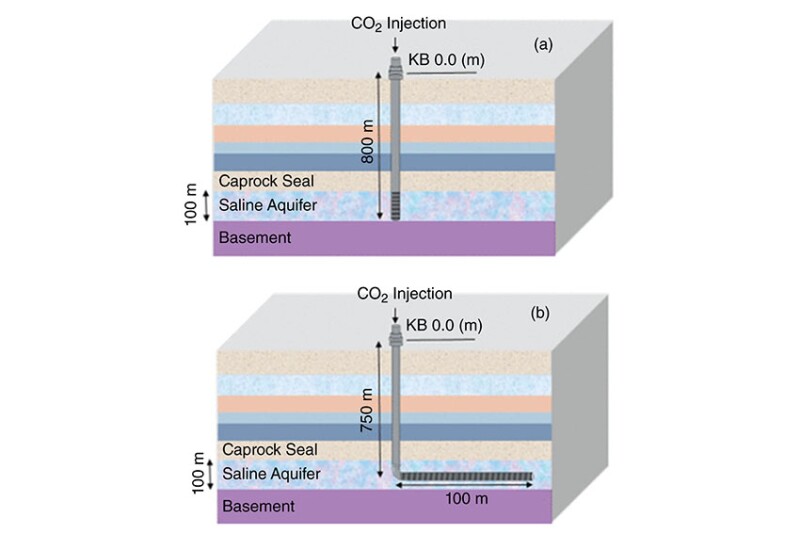

Horizontal and multilateral wells, commonplace in oil and gas operations (Fig. 4), offer significant advantages for CO₂ storage. A deviated or horizontal well greatly increases the well-reservoir contact area, which boosts injectivity and allows the same injection rate to be achieved at lower pressure drawdown. Simulation studies have shown that CO₂ injected through a horizontal well will spread more broadly through the formation, in contrast to the localized, gravity-dominated plume from a vertical well. The horizontal injection yields a larger swept volume and promotes more uniform saturation, thereby engaging more of the reservoir’s pore space.

Importantly, a wider spread of CO₂ leads to more CO₂ being trapped as immobile residual phase and dissolved in brine, enhancing the storage security and efficiency (Machado, et al.). Furthermore, advanced completion technologies like outflow control devices (OCDs) can be deployed in horizontal or multibranched injection wells to refine the injection profile. These downhole flow-control devices (analogous to inflow-control devices in production wells) help distribute CO₂ evenly along the wellbore even in the presence of variable permeability and thief zones. By choking flow into the higher-perm sections, OCDs force CO₂ into lower-perm regions, which enhances sweep efficiency and prevents one zone from taking all the injection.

This balanced outflow limits local pressure hot spots and effectively lowers the bottomhole pressure needed for a given injection rate.

In summary, the literature and field experience (i.e., Sleipner, Snøhvit) indicate that moving from simple vertical wells to horizontal or multilateral wells, ideally equipped with modern flow control, can markedly improve CO₂ injectivity, distribute the CO₂ plume more uniformly, and avoid early pressure limits in geological storage.

In conclusion, as geological carbon storage scales up, the need for more advanced ways to manage CO₂ underground increases. The highlighted techniques for reservoir management via composition, temperature, and pressure swing injection—offers operators tools to steer CO₂ behavior in the reservoir, increase sweep efficiency, and reduce gravitational segregation. While advanced well design, especially horizontal and multilateral wells with flow control, enables more-even injection, higher storage capacity, and reduced risk of overpressurization.

These strategies show the real value of applying oil and gas experience to CCS. But to move from theory to large-scale impact, more field trials are needed. As we aim to store billions of tonnes of CO₂, smart, flexible, and data-driven reservoir management will be just as important as CO₂ capture.

For Further Reading

A Criteria-Driven Approach to the CO₂ Storage Site Selection of East Mey for the Acorn Project in the North Sea by J. Alcalde, N. Heinemann, A. James, C.E. Bond, and S. Ghanbari, et al., Marine and Petroleum Geology (2021).

SPE 171798 Composition Swing Injection for CO₂ Storage and EOR by B. Nazarian, A. Cavanagh, P. S. Ringrose, and B. Paasch.

Reservoir Management of CO₂ Injection: Pressure Control and Capacity Enhancement by B. Nazarian, R. Held, L. Høier, and P. Ringrose, Energy Procedia (2013).

Dissolving Nonionic Surfactants in CO₂ To Improve Oil Recovery in Unconventional Reservoirs via Wettability Alteration by L.C. Burrows, F. Haeri, D. Tapriyal, S. Sanguinito, P.G. Shah, P. Lemaire, D. Crandall, R.M. Enick, and A. Goodman, Energy & Fuels (2022).

Review of WAG Field Experience by J.R. Christensen, E.H. Stenby, and A. Skauge, SPE Reservoir Evaluation & Engineering. (2001).

Pore-Scale Dynamics in Carbonate Reservoirs: The Influence of Heterogeneity on CO₂ Storage in Indiana Limestone by N. Darraj, C. Spurin, S. Manoorkar, S. Berg, M.J. Blunt, R. Pini, V. Cunsolo, and S.C. Krevor, Proceedings of Greenhouse Gas Control Technologies Conference (2024).

Heterogeneous Saline Formations for Carbon Dioxide Disposal: Impact of Varying Heterogeneity on Containment and Trapping by M. Flett, R. Gurton, and G. Weir, Journal of Petroleum Science and Engineering (2007).

Horizontal Wells for Enhanced CO₂ Storage in Saline Aquifers by H. Firoozmand and Y. Leonenko, Energy & Fuels (2024).

Accelerating CO₂ Dissolution in Saline Aquifers for Geological Storage–Mechanistic and Sensitivity Studies by H. Hassanzadeh, M. Pooladi-Darvish, and D.W. Keith, Energy & Fuels (2009).

Net Zero Roadmap: A Global Pathway to Keep the 1.5°C Goal in Reach (2023 Update) by International Energy Agency, Paris: IEA (2023).

Injection Strategies for CO₂ Storage Sites by International Energy Agency (IEA) Greenhouse Gas Research and Development Program (2010).

Experimental Investigation of Miscible and Immiscible Water-Alternating-Gas (WAG) Process Performance by M.M. Kulkarni and D.N. Rao, Journal of Petroleum Science and Engineering (2006).

Potential Benefits of Horizontal Wells for CO₂ Injection To Enhance Storage Security and Reduce Leakage Risks by M.V.B. Machado, M. Delshad, and K. Sepehrnoori, Applied Sciences (2023).

A Review of Recent Developments in CO₂ Mobility Control in Enhanced Oil Recovery by O. Massarweh and A.S. Abushaikha, Petroleum (2022).

The Defining Series: Multilateral Wells by Schlumberger, Oilfield Review (2017).

Fundamentals of Enhanced Oil Recovery by L. Lake, R.T. Johns, W.R. Rossen, and G.A. Pope, SPE, (2014).

Nihal Darraj, SPE, is a carbon capture and storage (CCS) researcher at Imperial College London and CO₂ storage lead at the Global CCS Institute. With more than 8 years of experience in the oil and gas industry, she brings expertise in reservoir engineering, CO₂ storage, and subsurface solutions. Darraj previously served as CCUS development manager at Heidelberg Materials and as a senior reservoir geomechanics engineer, focusing on CO₂ storage, produced-water reinjection, and waste management. Darraj is a committed industry leader, having cofounded and chaired the SPE Diversity and Inclusion Committee and led the SPE International Young Member Engagement Committee. She has also contributed to the UN Economic Commission for Europe Group of Experts on Carbon Neutrality. She is in the final year of her PhD at Imperial, researching CO₂ storage in heterogeneous formations, and holds degrees from Imperial College London and Alexandria University.