When the pump breaks down and the oil stops flowing, it’s mostly likely due to a failed sucker rod.

“The statistics are pretty strong. While you would think the rod pump or the progressing cavity pump is the component with the most problems, it is the rod string” that is most often to blame, said Lonnie Dunn, vice president for technology at Lifting Solutions.

That’s a critical fact for Dunn who works for the biggest maker of what are known as continuous sucker rods. Rather than connecting individual rods into a string long enough to run from the surface to the pump, a single long rod is run into the well like coiled tubing.

While he was talking up coiled sucker rods at the SPE Artificial Lift Conference and Exhibition, a competitor at the conference, ChampionX, was announcing a first: a protective anodic coating for its continuous sucker rods that prevents corrosion and reduces the drag when a rod rubs against the surrounding tubing (SPE 209751).

Unlike competitors that have relied on coatings that provide a physical barrier, ChampionX’s defense relies on a powdered metal coating that short-circuits electrochemical reactions that can cause rapid corrosion.

This is an emerging technology where the key components are long-proven. Continuous rod was patented nearly 50 years ago, and methods using anodic corrosion protection methods have been around even longer with uses ranging from protecting subsea risers to galvanized nails.

Still both ideas are new in this slow-changing service sector, where there has been little change in the dimensions of the rods, and key design elements are usually based on API specifications.

These companies are among a handful of innovators working to convince operators that a continuous rod is a better choice at a time when wells present more challenges, from wellbores that curve by design or by accident to reservoirs producing increasingly corrosive fluids.

It has been a slow change because “sucker rods have been around a long time and the product and servicing practices are well established whereas continuous rod, especially on the servicing side, represents a significant change,” Dunn said.

While there are advantages, from faster running times to reduced failures, when it comes to this long-established oilfield commodity, he suspects some customers assume “everything that can be done is done.”

Continuous rods eliminate the time required to make the hundreds of connections needed to make up a rod string. The risk of connection failures is reduced by replacing multiple rods with a long rod requiring connections only at the pumping unit on the surface and the pump downhole.

To back up the promise of more-durable rods, the companies in this sector are adding corrosion-resistant coatings. “The general consensus is that the wells are going to get more and more corrosive, and the industry will be going after oil and gas in harsher conditions,” said Alex Perri, product line director for ChampionX.

Making It Stick

ChampionX is trying to leapfrog competitors who have been selling continuous rod with protective barrier coatings.

Lifting Solutions covers the surface with a barrier layer of high-density polyethylene, while Weatherford uses its own proprietary nonmetallic coating, Dunn said.

Rod coating is a tricky engineering challenge on multiple levels.

Anything applied to the surface of a rod must endure rough handling from the time it is run through the grippers during installation to the constantly moving rod rubbing against the tubing, which is increasingly likely to happen in curving wellbores.

When Perri explained the thinking behind ChampionX’s coating development, it amounted to a critique of the competition whose coatings are designed to serve as barriers to protect the steel rods from the corrosive fluid found in many wells.

When ChampionX surveyed customers using those rods with barrier coatings, he said they responded that they worked well initially, but wore off over time, reducing the protection over time.

Dunn responded that they have run over 3,000 coated, continuous rod strings in corrosive directional well applications, extending run times from as low as a few months with bare rod to several years or more with their coated rod.

Based on ChampionX’s paper, its coating can reduce the friction by 25% when in contact with metal and can continue protecting areas where it is has been rubbed off.

ChampionX’s methods draws on scientific explanations that have been around for a long time on how chemical reactions can create an electric current and lead to corrosion and on recent advances in material sciences that were used to create a tough coating that tightly adheres to the rod.

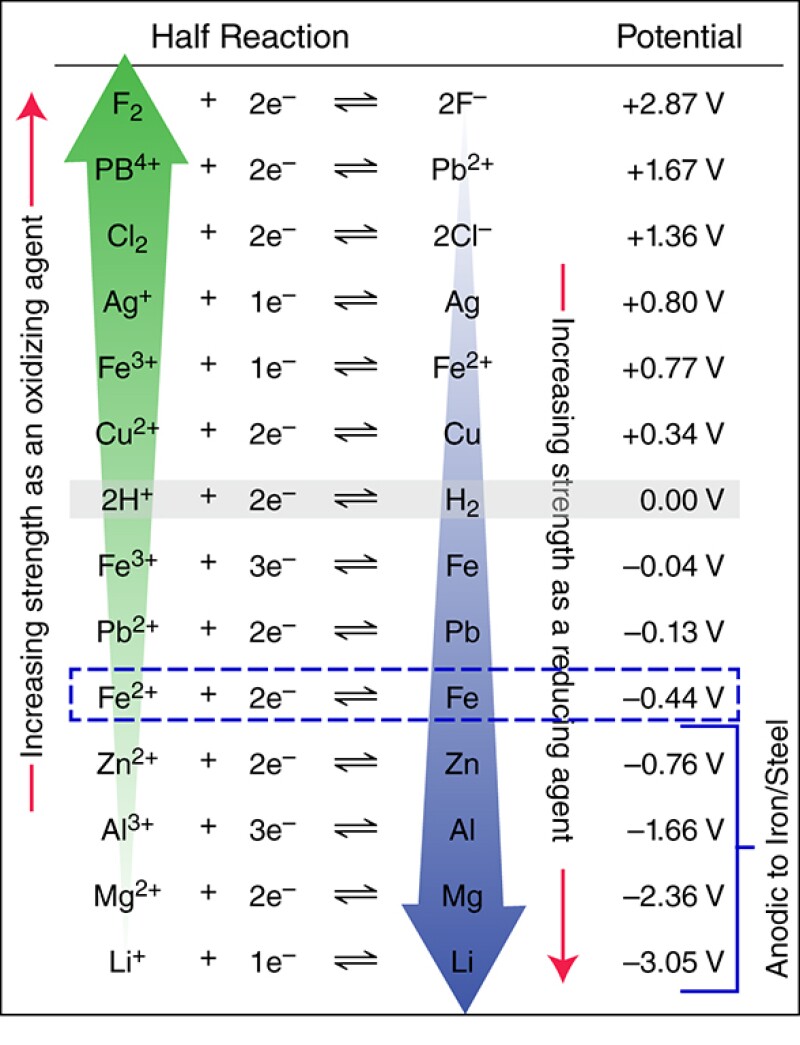

Anodic protection methods limit corrosion by adding a coating made from a metal that is sacrificed to protect the steel rods from corrosion.

With no protection, the acidic environment in a well—ChampionX’s test fluid contained hydrogen sulfide (H2S) and carbon dioxide (CO2)—will interact directly with the steel rod. Electrons from the steel travel through the well fluid causing the steel to rapidly corrode.

It basically works like a battery. “The iron is both the anode and cathode, and the fluid containing H2S and CO2 acts as the electrolyte. The complicated interactions between these components results in an oxidation reaction due to the loss of electrons on the steel surface, leading to pitting and more-extensive damage if left untreated,” said Angela Sultanian, a senior material engineer for ChampionX.

The coating short-circuits that process by adding a metal whose charge, relative to the iron, makes it the anode as its electrons flow to the steel, disrupting that destructive reaction. This protection continues even if some of the anodic coating has been rubbed off or scratched because it does not depend on creating a physical barrier.

Still, ChampionX worked to minimize those gaps by developing a method to strongly bond the anodic coating to the flexible surface of the coiled tubing using a continuous application method that lowered the cost of applying the coating to thousands of feet of rod.

This protection does not last forever. It is limited by the volume of the metal in the anodic protection coating. Rod-coating engineering requires balancing the need to maximize the life span for rods, which is ultimately limited by metal fatigue, with the price buyers are willing to pay for an oilfield commodity item.

While ultrahigh-performance protective coatings have been developed by the US National Aeronautics and Space Administration (NASA), they cost more than anyone is willing to pay to protect a sucker rod, Dunn said.

Downhole Comparisons

ChampionX tested its coating by inserting a 2,620-ft-long rod into a well where the fluid was corrosive (2.3% H2S and 15.7% CO2). The upper 820 ft of the steel rod (AISI 4120M) was uncoated while the lower 1,800 ft were treated with its anodic coating.

After 22 weeks, they pulled the sucker rod and observed corrosion damage on the untreated section, with pitting and as much as a 5% reduction in the diameter in spots. The paper reported “no significant wear” in the coated lower section.

At 38 weeks, the uncoated section of the string broke at a point a few feet below ground level where there was “considerable corrosion damage,” the paper’s authors wrote.

They replaced the uncoated section and moved it to the lower part of the rod below the coated section. Since then, the combination has been running for 158 weeks without incident, which Sultanian said is a “dramatic increase in run time.”

The test fits the pattern of longer reported run times for continuous rods with corrosion protection. But comparisons are tricky because the run time for sucker rods varies widely depending on the chemistry of the well, the rod specifications, the quality of the wellbore, and how well the pumping system is maintained, among other factors.

Makers of continuous rods are making investments in coatings presuming greater protection will be required in the future, Perri said.

Stalled in the USA

The toughest competition faced by the companies selling continuous rod is traditional sucker rods.

Coiled rod is widely used in Canada, where it was born, and has spread to Oman, Colombia, and a few other smaller oil-producing countries. In the US, demand for continuous is relatively strong in California, and there are users in North Dakota, Texas, New Mexico, and Colorado, including some testing or potential customers, Dunn said.

Reasons for the slow uptake in the US range from a lack of equipment and crews to run continuous rod—which is getting better—to the time-consuming task of convincing sucker rod users that there is a better sucker rod.

Change requires considering the tradeoffs, Dunn said.

On one hand, eliminating connections removes the cylindrical collars that stand out from the rod. These 4-in.-long connectors create a point of contact every 25 ft that can wear through the tubing as it spins or oscillates. Dunn said guides are often added to jointed sucker rods to distribute the contact more evenly, but this introduces flow restrictions, turbulence in the tubing, and adds to the cost.

Continuous rod can also come in contact with the tubing, but its uniform surface means the force is more widely distributed than with a collar. However, continuous rod is at a disadvantage in wells that produce wax due to the absence of connections or guides that serve to prevent wax buildup in the tubing, he said.

It is not as if the problems associated with the hundreds of connections needed for an average Permian well are unknown. A paper from Occidental Petroleum presented at the lift conference offered a detailed analysis of the high rate of failures in an operation using fiberglass sucker rods.

Based on the analysis and feedback from those in the field, the connectors were the weak link causing a high percentage of the rod breaks. Occidental responded by making changes, including a program to ensure the connections were made properly (SPE 209731).

Dunn acknowledged that attention to detail could significantly reduce the failure rate, but going to continuous rod would eliminate the source of the issue entirely.

Selling continuous sucker rods in the Permian will require adapting the product to the enormous size of the pumping units and the depth of the prolific wells. To do so, Dunn said, “will require adapting to the deep, highly loaded wells and the tortuosity associated with their wellbore profiles, which represent a step up in difficulty from the current continuous rod application base.”

Proving the value of continuous sucker rods requires convincing potential customers that they really do last a lot longer, “which means the testing process takes time,” Dunn said.

For Further Reading

SPE 209751 Anodic Coiled Rod Mitigates Corrosion Damage in Well With Aggressive CO2, H2S Conditions by Alexander Claudio Perri and Angela Sultanian, ChampionX.

SPE 209731 Fiberglass Sucker Rod Cost-Effectiveness: A Case Study From the Permian Basin by Melanie Brewer and Chaohui Su, Occidental; Steve Gault, Occidental (Retired)