Extracting maximum value from oil and gas wells has never been more vital. Today’s volatile oil prices are influenced by global geopolitical and increasingly, climate events. Russia’s invasion of Ukraine, the pandemic, and recent natural disasters that degraded US oil production are just a few factors fuelling the latest surge in prices.

Regardless of the price-per-barrel, optimising production is crucial. Keeping operations running and improving efficiency when opportunity strikes is critical, and this is where well monitoring comes into its own.

Ninety percent of the world’s oil and gas wells are classed as unconnected, meaning they are still monitored manually. Yet, we can be certain that a significant number of these wells will encounter a production downtime issue at some point in their life. As a matter of fact, 33% of wells will encounter an integrity issue affecting production uptime at some point in their life. With statistics like these, it’s clear that well monitoring should be a strategic priority for every operator, particularly as oil prices rise. Any downtime or leak can be a disaster for safety, the environment, and for business.

Whether a well is producing 10 or 1,000 barrels a day, monitoring your wells unlocks significant improvements in well efficiency, reduces downtime, and enhances overall safety. And the more remote or lower-producing the well, the greater the potential benefits of monitoring.

In terms of increasing oil production, there are three key benefits of using more granular and more accurate well data.

Reduce Downtime by Responding Faster to Integrity Issues

Firstly, during production booms, engineers have one goal: to get resources out of the ground as quickly as possible. Time spent checking or monitoring wells manually or working out precisely which well has an issue is time wasted. By using real-time data and digital technology, engineers can react to and tackle issues faster and return their focus to production.

A good well-monitoring system can immediately direct engineers to the wells that need attention at the moment they need it. For example, by identifying dangerous increases in temperature or pressure that need addressing, and then ensuring the right engineers can be sent to the right wells at the right time.

Optimise Production with Data

Measuring, monitoring, and taking action to produce oil as efficiently as possible using regular, reliable, and accurate data optimises oil production. Well monitoring makes that possible, even on low-producing wells or those in off-grid locations.

Connected wells can use data insights to adjust their operations by the hour. For example, if a well is way off its production target, data such as tubing pressure or production flow can help engineers get production back on track.

Unconnected wells can be inefficient and even hazardous without data. Infrequent data can be equally dangerous. At best, wells might be checked once a day. At worst, weeks (or months) can pass between well checks. Whatever the case, with well-integrity issues, for example, there’s the potential that time and production is lost on a well that could have been producing more, had the team been alerted to it.

Improve Safety, Save Time, and Reduce Costs

The cost of repeated trips to monitor wells can quickly add up, as can the amount of time teams spend travelling to them. This is especially the case where wells are offshore or in less-connected parts of the world. Well monitoring eliminates the unnecessary travel and time costs associated with visiting wells without a clear need or plan.

Sending teams of engineers to monitor offshore or remote wells is also dangerous. From bad weather, to broken vehicles, to lack of local security, to the remote nature of the locations themselves, there’s a lot that can go wrong. There’s also often a poor communications network in these situations, and little access to local infrastructure or cellular communications.

A solid well-monitoring system saves team time, reduces travel costs, and eliminates this kind of travel risk for oil company employees. For operating companies, it’s an obvious and easy win because it generates reliable data, 24/7, that can be used to diagnose and solve problems in the field without hassle.

Satellite Technology Changes Everything for Unconnected Wells

The value of well-monitoring technology is clear.

Yet 90% of wells are still unconnected and manually monitored. Why? Because traditional well-monitoring technologies are expensive and complex to install. They haven’t been developed to meet the needs of the majority of wells—remote onshore wells, unmanned satellite platforms, low-producing wells, old wells or those that are to be abandoned.

What does the ideal well-monitoring technology look like? It needs to be simple but complete, affordable and scalable, and of course flexible.

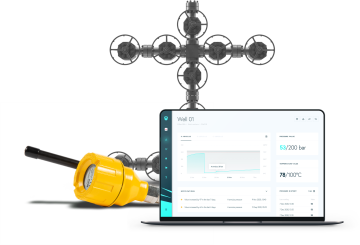

Hiber’s solution to this challenge is HiberHilo, a satellite-enabled well-monitoring technology that means producers can digitally monitor remote, low-producing or old wells at an affordable cost via an all-in-one subscription.

HiberHilo is available worldwide. The solution connects sensors on wellheads via a wireless, solar-powered gateway to satellites, and then on to an API or secure online mobile or desktop dashboard that can be monitored from anywhere in the world.

Multiple wellheads with sensors can be connected to the same gateway within a five-mile radius. The sensors relay readings regularly to give a 24/7 view of the status of any well, no matter how remote, so issues such as production downtime or leaks are immediately identified and quickly rectified.

It’s simple and easy to install. No local power is needed, HiberHilo is fully battery- and solar-powered. The subscription model means there’s no capital expenditure and no hidden costs.

With remote wells notoriously difficult to monitor and most encountering integrity issues or production issues at some point in their life, HiberHilo makes monitoring remote assets in the least-connected parts of the world safer, cheaper, and easier. The breakthrough cost and potential ROI also makes the digitisation of well monitoring possible for even the lowest-producing wells, helping in turn to boost production.

Major Oil Companies Turn to HiberHilo Well-Monitoring Technology

HiberHilo has been rolled out around the globe to some of the world’s largest energy companies. Shell and Continental are already using Hiber’s well-monitoring technology to improve remote well monitoring.

Shell was in fact one of the first major oil companies to turn to HiberHilo.

When exploration company the Nederlandse Aardolie Maatschappij (NAM) and Shell wanted a better way to monitor well integrity, they embarked on a joint project to test HiberHilo on a well-abandonment project that was still connected to a pressure- monitoring system.

The purpose of the test was to evaluate the speed and ease of installation, compare the output of the sensor to an existing wired measurement system, and evaluate the future possibilities of this approach. Both companies wanted a system that was easy to install, easy to use, and easy to trust.

The entire installation took less than three hours, with the sensors connecting to the satellites within 15 minutes. The installation was so fast that the engineers estimated they could have done another 15 installations in the same day, making this approach suitable even in remote areas.

Shell’s technical team was impressed with the satellite-based approach.

“After testing HiberHilo, the opportunity was clear,” said Ian Taylor, Global Principal Technical Expert for well integrity at Shell.

Shell and Hiber now have a global framework agreement that lets Shell subsidiary companies and entities transition to satellite IoT and use HiberHilo. It has already been installed at Shell operations in the North Sea.

Making Well Monitoring Accessible

Well-monitoring technology has traditionally been unreliable in remote areas without cellular connectivity and too expensive for all but the highest-producing wells in other locations.

HiberHilo is a game changer for the oil and gas industry. Producers can monitor wells via low-cost, low-power satellite connectivity that makes well monitoring affordable and increases oil production, reduces downtime, and improves safety through access to better data.