If you work in the field of process and separation, chances are you have come across computational fluid dynamics (CFD). CFD produces a wide range of emotions from abject fear, often involving flashbacks to a long-forgotten university class and a dizzying array of partial-differential equations, to curiosity and even enthusiasm. The purpose of this article, the seventh of the Oil and Gas Facilities Savvy Separator Series, is to allay those fears, answer some questions, and help you become an educated consumer of CFD.

Many would start by asking the “so what” question: Why and when should CFD be cared about? This question will be answered, followed by a brief introduction to CFD including the major multiphase models, some FAQs, and a short case study example of CFD and automated design exploration being applied to a cyclone separator. All of which will be achieved without recourse to a single equation!

So why should CFD be part of the separator design?

In today’s “lower for longer” market, cost reduction is front and center for all. CFD helps in all the phases of a project from reducing the initial project costs (Capex), operating costs (Opex), and can help manage project extensions such as tying in additional wells to an existing facility.

Suppose you are designing a subsea separator, whose job is to separate gases and liquid prior to pumping. Ensuring the separator meets its process requirements is important: the pump or compressor downstream will not perform as desired if there is carry-over or carry-under (liquid in the gas stream and gas in the liquid stream). Should this occur, operations will have a very expensive challenge to resolve.

In addition to ensuring it meets minimum process requirements, there are other design considerations. There may be a need to reduce its weight to ease installation; understand how changes in upstream piping impact performance to provide a standardized design able to connect with many subsea processing systems configurations; minimize its size to reduce the amount of real estate used; and minimize the pressure drop and the use and cost of internals.

Hand calculations can be used such as Stokes’ law to estimate the required residence time, but this involves assumptions about the flow (e.g., no short-circuiting or even distribution across the flow area). Physical tests can be run, however these present their own challenges: cost and time; difficulty visualizing the complex multiphase flow; testing with process fluids; and high pressures and temperatures introduce significant additional cost and safety concerns.

Using CFD, the flow patterns in upstream piping, inlet devices, and within the separator can be predicted to ensure adequate residence time. Each separation mechanism can be studied such as estimating the tendency for liquid droplet re-entrainment due to high gas velocities, and improving the performance of internals by increasing the uniformity of the flow to the demisters. An SPE webinar, “CFD Optimization of Scrubber Inlet Design,” presents examples.

All of which can be achieved with relative ease and speed, using actual process fluids, temperatures and pressures. When a thorough understanding of the initial design is obtained, we can run “what if” design studies to see how the design can be improved. In short, successful use of CFD results in discovering better designs, faster and at a lower cost.

This is predicated on the assumption that the CFD study was conducted correctly, and therefore, the results can be trusted.

The good news is many of the uncertainties of CFD can be systematically tested for (such as a mesh refinement study, the details of which will be presented later in this article), or can be interrogated by an engineer who understands the relevant physics at hand (and not CFD). A common concern is that results must be “tuned” to be accurate. This is not necessarily the case; accuracy can be obtained through systematic testing, quantification and minimization of uncertainty and error, and by ensuring the problem is adequately posed; modeling assumptions are appropriate for the problem at hand.

The first step in interrogating a CFD solution is to use good engineering judgment. Does the flow field make sense, and if not, why? How does it compare with hand calculations, prior designs that have validation data, and simpler analysis methods? In the early stages, CFD mistakes are often typos, so if it looks like the code solved a different problem than the one being investigated, there’s a good chance it did.

Next, it takes a deeper explanation to understand the major steps in the simulation process and the potential impacts of the steps on the results.

CFD attempts to solve the Navier-Stokes equations. These describe the behavior of fluids, so if we can solve them, job done. Unfortunately, solving the Navier-Stokes equations is computationally intractable, so for all practical problems the Reynolds Averaged Navier-Stokes (RANS) form is used. These suffer from the “closure problem”: having more unknowns due to averaging, which are resolved through the use of turbulence models.

Models are also used to incorporate more advanced physics such as multiphase flow dynamics. The main multiphase flow models will be covered later.

Setting up a CFD study involves four steps:

- Define the domain of interest: what is the geometry, where does the flow enter and exit, and what are the conditions on the boundaries, such as the velocity at the inlet?

- Discretizing or meshing the domain. Rather than solving for the fluid behavior (velocity, pressure, etc.) at every point in space, we segment the volume using a mesh, then solve the equations only at the center of each cell in the mesh. Think of a separator filled with Lego bricks; CFD will tell you the velocity, pressure, temperature, etc. at the center of each brick. For completeness, in time-varying problems time is discretized by solving for time increments, such as every 0.1 seconds.

- Select which physics to simulate: is the flow single or multiphase, thermal or isothermal, etc.?

- The CFD program then iteratively solves the equations to convergence.

These steps also represent the four areas of uncertainty, and where attention should be focused.

First, defining the domain of interest and the boundary conditions: If a 3D CAD model or drawings of the geometry exist and are available, defining the domain typically is not an issue. More challenging can be defining the flow conditions at the inlet and outlet. In separator simulations it is typical to prescribe a droplet size distribution at the inlet, which requires knowing or estimating this. Typically, boundary condition information is available from other analysis methods such as 1D models of the system, calculation using CFD by extending the domain of interest upstream to some point where there is less uncertainty, or by hand calculations (e.g., to estimate minimum droplet sizes). The engineer who performed the CFD study should be able to explain which conditions were used, what these mean physically, and why they are appropriate.

Secondly, the domain (geometry) needs to be discretized or meshed. This is an important and potentially time-consuming part of the analysis. A good mesh begets good CFD.

The mesh (number, size, and type of cells used) can influence the answer. As an example, if a CFD simulation is trying to simulate a vortex using one cell, the solver only has one point at which it calculates the velocity and pressure to represent the vortex. As the number of cells is increased, decreasing the size of each cell, the resolution and therefore accuracy of the representation of the vortex improves. A similar approach is used to ensure or minimize the influence of the mesh over the solution; the mesh is progressively refined (reducing cell size) until quantities of interest, such as pressure drop, stop changing. A short note on a well-established method for grid convergence studies can be found in the American Society of Mechanical Engineers’ Journal of Fluids Engineering.

Fig. 1 shows the different cell types: hexahedra (six sides), polyhedra (many-sided, but typically soccer ball-shaped with 12–14 sides) or tetrahedra (four-sided).

|

| Fig. 1— Tetrahedra (blue), hexahedra (green), polyhedral (red). Images courtesy of CD-adapco. |

Historically, tetrahedral meshes were often used, since building hexahedral meshes was difficult and time-consuming, particularly for complex geometries. This is undesirable as tetrahedra have poor numerical properties; they artificially make the fluid behave as if it’s more viscous. As a consequence, many more tetrahedral cells are required to attain the same level of accuracy as when using hexahedral or polyhedral meshes.

Fortunately, meshing packages have improved significantly in the last decade, so it is now possible to build polyhedral or hexahedral meshes, even on complex geometries, without significant overhead.

Thirdly, after building the mesh, the engineer must select which physics to consider. One benefit of CFD is the ability to simplify problems to consider only the physics of interest, making it easier to interrogate and understand results and trends. This is also a double-edged sword: oversimplify and important effects can be missed. As with boundary condition selection, the engineer performing the analysis should be able to explain which models have been used, what the physical meaning of these models is, and why they are appropriate for the problem at hand.

In the separator world, multiphase modeling is key. There are three main multiphase models used in CFD: free-surface or volume of fluid (VOF); Eulerian-Lagrangian multiphase, often shortened to Lagrangian multiphase (LMP); and Eulerian multiphase (EMP).

In the VOF approach the interface between the phases are resolved with the mesh. If droplets of water fall under gravity through air, CFD can capture the motion of the droplet using the VOF model (Fig. 2). The caveat being there must be adequate mesh resolution to capture the shape and motion of the droplet in the mesh.

|

| Fig. 2—Droplets modeled using the volume of fluid method. |

Consequently, this model is well-suited for flows that have a well-defined interface between the phases, such as stratified flow, where the mesh can be refined locally to capture the interface. A common application of VOF is to model the sea and its behavior around ships: there is a clear interface between the sea and the air.

VOF can be used to model flows other than stratified, it just means that the mesh needs to be refined to capture the multiphase effects at the interface between the phases, such as entrainment of fine droplets into the gas phase. However, this increases the computational cost of the analysis. In separation, VOF is often used to evaluate the bulk flow properties of the vessel.

When the flow is dispersed, either LMP or EMP is typically used.

In LMP the continuous flow field is solved using the RANS CFD approach described earlier. In the example of droplets falling through air, the air is the continuous phase and the droplets are the dispersed phase. Confusingly, the method used to solve the continuous phase is Eulerian, in that there is a fixed mesh and the motion of the flow relative to that mesh is solved for. Consequently, the full name for LMP is Eulerian-Lagrangian multiphase, but the Eulerian is dropped for expediency.

For the dispersed phase, the trajectory of each particle or droplet is solved for using Newton’s second law of motion. The calculation of the droplet or particle motion is performed from the reference frame of the moving droplet, rather than the fixed mesh, which is known as a Lagrangian method. In order to reduce the computational cost and make it applicable to scenarios with large numbers of droplets, each droplet represents an ensemble of droplets. Inputs to the motion calculation include submodels, such as for the drag force and dispersion of droplets or particles due to turbulence. Additional submodels can be introduced to include breakup and coalescence of droplets. The interaction between the phases can be either one- or two-way: one-way is when the motion of the droplets is influenced by the continuous phase, but the continuous phase does not “see” the droplets; two-way is when both phases influence each other. The one-way coupling is often applied.

This method is an efficient and accurate way to model droplet or particle flow. Where it becomes less applicable is when the volume fraction of droplets or particles is high. Opinions on the volume fraction cutoff vary, but are usually in the 5% to 10% range, at which point the model accuracy and stability deteriorate. For particle flows, more advanced models can be used to address this, such as discrete element method (DEM) or multiphase particle-in-cell (MP-PIC). In separation, LMP is often used to study the motion of droplets in the gas stream.

For Eulerian multiphase, the full RANS equations are solved for each phase. Using the concept of “interpenetrating continua,” the continuous and dispersed phases interact through source terms for drag, lift, virtual mass, and turbulent dispersion. This makes it an immensely flexible model, able to simultaneously handle any number of phases and any range of volume fractions. Submodels can be included to account for additional physics such as breakup and coalescence of droplets or bubbles, or heat and mass transfer.

The disadvantages of EMP are: first, that each set of RANS equations comes at a cost (studying many particle sizes or phases becomes computationally expensive); and second, the user needs to understand, and choose, appropriate submodels and settings. The downside of EMP’s flexibility is that it can be applied to a wide range of multiphase flows, which results in multiple submodels to be understood and applied.

In the analysis of separators, EMP can be used to model the full vessel, but is particularly effective in mixing regions where volume fractions exceed the limitations of LMP, and tracking small droplets or bubbles with VOF is computationally expensive.

Fourthly, having built the mesh, specified boundary conditions and chosen appropriate modeling assumptions, the solver uses iterative techniques to successively improve the solution until “convergence” is attained. Convergence is defined by the National Agency for Finite Element Methods and Standards.

Mathematically, convergence describes the limiting behavior, particularly of a series toward its limit. In CFD, the series is the flow field (values for velocity, pressures, etc.). The flow field reaches its limit when the values for velocity, pressure, etc. stop changing from iteration to iteration.

Convergence is often judged by monitoring residuals. Residuals measure the amount by which the discretized equations are not satisfied, which is not the error in the solution. A typical rule of thumb is that residual values should have dropped by three orders of magnitude.

If the residual values do not drop and the flow field continues to change, this may indicate a problem. The problem may relate to assumptions taken, such as assuming steady-state conditions. Since fluid dynamics involves inherently unstable phenomena, such as turbulence, it may not be possible to attain a steady-state solution. Alternatively, it may indicate problems such as poor-quality cells in the mesh, or an ill-posed problem such as the location or values of boundary conditions.

Case Study: Design Space Exploration of a Gas/Solid Cyclone To Improve Separation Efficiency

Having described the steps in the setup of a CFD study and built confidence in the result, the following is an example of how CFD should be used to understand and improve design and performance.

Fig. 3 shows (from left to right) the geometry, streamlines through the device, with an isosurface showing areas of low pressure, volume rendering of pressure contours, and a comparison between CFD using multiple methods and experimental data for mean axial velocity at two locations in the cyclone. The purpose of these simulations was model verification, which is why multiple methods were used for the same case.

|

| Fig. 3—Geometry, flow visualization, and experimental comparison for baseline design. |

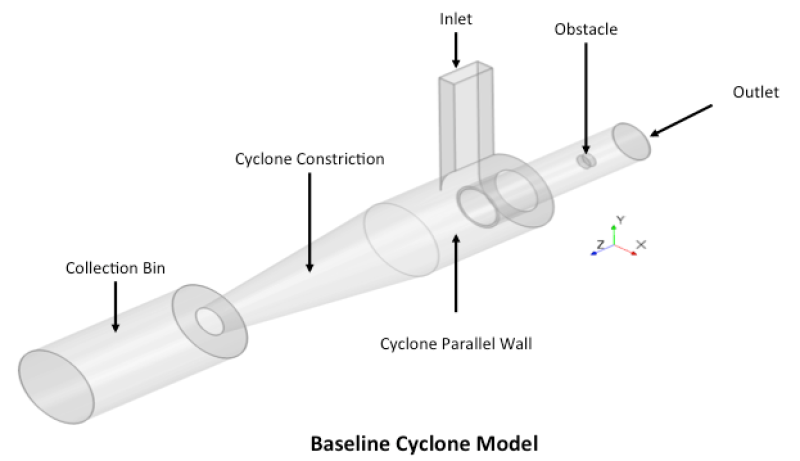

The baseline geometry for the design study (Fig. 4) is from an European Research Community on Flow, Turbulence, and Combustion paper, in which the geometry and experimental data (laser Doppler velocimetry or LDV) of the mean velocity profiles across the cyclone are available. Having validated the base model, CFD allows us to explore design alternatives quickly and easily. It can also be used in conjunction with tools that will automate the simulation process and efficiently explore the design space. In this case the HEEDS software from CD-adapco was used.

For the design space exploration study, a constant gas velocity of 25 m/s was applied at the inlet. Sand particles with a diameter of 1.2 µm were introduced at the inlet, such that they accounted for 1% of the volume fraction of the flow. LMP with a one-way coupling to the continuous phase was used, along with the Reynolds stress turbulence model (RSM).

The automation and design space exploration tool HEEDS uses algorithms to predict where next to look in the design space. HEEDS requires the engineer to provide:

- Design objective(s). There can be more than one and these can be competing. In this case the objective is to maximize the separation efficiency of the cyclone.

- Constraints can be applied. In this case the pressure drop across the separator cannot exceed a certain value, else the design will be deemed infeasible.

- Different load cases to be evaluated. For example, the separation performance at different particle loadings.

- Design variables, their extents and sensible increments are defined. In this case we vary the radius of the cyclone, the length of the constriction and parallel wall sections.

Many different approaches have been developed to help explore the design space efficiently. These are often referred to as optimization algorithms and include design of experiments (DOE), genetic algorithm, downhill simplex, and particle swarm (among others). Optimization is often a misnomer, since for most industrial applications no single optimal solution or design exists. However, these techniques can be highly effective in identifying better designs.

An impediment to the application of these methods is their multitude; users must understand which method to use for any given scenario. HEEDS uses a hybrid and adaptive algorithm called SHERPA, which will switch between different exploration methods (DOE, genetic algorithm, etc.) depending on information it has about the analysis, such as the number of variables, and the amount of time and resources available. The benefit of using these methods is that they find better designs in less iteration than an engineer on his or her own, or other optimization methods (Fig. 5).

|

| Fig. 5—The geometry of an improved design, the velocity magnitude along a plane section through the center of the cyclone, and a design study history showing the progressive improvement in separation efficiency. |

In this case, 125 designs were evaluated over 5 days (always running two cases concurrently). After 44 tries, the separation efficiency was improved by 19%, while increasing the pressure drop by approximately 1%.

|

| Fig. 6—A correlation plot showing the relationship and degree of correlation between two variables. |

The correlation plot shows the relationship and degree of correlation between two variables, such as the radius of the cyclone and the cyclone separation efficiency. The numbers on the top right show the correlation between the two variables represented in the square (1.0 indicates perfect correlation).

The correlation plot helps the engineer to interrogate large amounts of data (more than 100 designs), and understand quickly what influences the design. In this case, the cyclone radius has a significant impact on its efficiency and pressure drop (correlation of 0.74 and 0.71, respectively).

Summary

To the nonspecialist engineer, CFD can be initially daunting, particularly in more advanced areas such as multiphase flow and separation. While detailed knowledge of submodels will remain with the specialist, nonspecialist engineers can critique CFD results by evaluating whether the physical meaning of the results can be explained, and asking about the modeling decisions taken and their anticipated influence on the results and quantities of interest. By introducing the main multiphase models used, this article aims to help in this process.

CFD complements other analysis methods (analytical or experimental). Its successful application can have a significant, positive financial impact on projects by reducing the cost of design, improving and validating equipment performance, and mitigating problems before they occur. Linking CFD with automated design space exploration tools can further speed the understanding and improvement of separator designs.

Alex Read has worked for CD-adapco for 14 years as a project engineer, run the customer support team for Northern Europe, and helped to found the company’s operations in Houston and São Paulo, Brazil, where he led both sales and technical teams. He now leads CD-adapco’s global activities in the oil and gas industry, helping the world’s leading companies to succeed through simulation. He holds undergraduate and graduate degrees in engineering and computational fluid dynamics, and an MBA.