The Savvy Separator Series started in 2015 as a way to share lessons learned in the design and troubleshooting of separators. The various contributing authors have a wealth of knowledge gained from personal experience from mentors and colleagues. It has been my privilege interacting with and learning from them as well as coaxing them to write the articles.

This article will be the final article of the series (no. 23). Although the series ends, we highly encourage you to share your experiences and lessons learned. In this article, the four authors share some of their recommended references, articles, and other information that you should know about, read, and have in your library.

—Robert Chin

The Savvy Separator Series started in 2015 as a way to share lessons learned in the design and troubleshooting of separators. The series has covered topics such as design, troubleshooting, droplet shearing, computational fluid dynamics (CFD), level control, vessel code, and installation to name a few.

In this series finale, the authors collectively share their recommended lists of information that you should know about, should read, or have in your library. The lists are, of course, not exhaustive, but should give the reader a very good understanding of separator design and troubleshooting.

Articles cited for additional reading provide some information on applications or more background details (basic and advanced) on a given topic. Although the focus has been gas/oil/water separation, some references/articles for distillation and water treating are also included because of their applicable and valuable insights.

Note that these lists are just some of the available information that are used to make sound engineering decisions for a given application or design.

I. References

The following references (or latest editions) represent a wealth of information for the engineering design and troubleshooting of oil and gas facilities.

a. Surface Production Operations, Vol. 1: Design of Oil Handling Systems and Facilities, 3rd edition (2007), and Vol. 2: Design of Gas-Handling Systems and Facilities, 3rd edition (2014) both by Maurice Stewart and Ken Arnold.

b. Perry's Chemical Engineers' Handbook, 9th edition, McGraw-Hill (2019). Editors D.W. Green and M.Z. Southard

c. Gas Conditioning and Processing, Vol. 1: Basic Principles, and Vol. 2: The Equipment Modules, John M. Campbell, 9th edition (2014).

d. SPE Petroleum Engineering Handbook, Vol. III: Facilities and Construction Engineering (2007); Larry Lake, editor in chief; Ken Arnold, author.

e. The Properties of Petroleum Fluids, 3rd edition (2017), PennWell Books, by William McCain Jr.

f. Handbook of Hydraulic Resistance, 4th edition (2008), Begell House, by I.E. Idelchik.

g. Droplet Separation, Wiley-VCH New York (1989), by A. Burkholz.

h. Mechanistic Modeling of Gas-Liquid Two-Phase Flow in Pipes (2006), SPE, by O. Shoham.

i. Produced Water Vol.1: Fundamentals, Water Chemistry, Emulsions, Chemical Treatment (2018), and Vol. 2: Equipment, Process Configuration, Applications (2019), Petro Water Technology, by John Walsh.

j. Process Design for Reliable Operations (2008), 3rd edition, Lieberman Books, by Norman P. Lieberman.

k. Distillation Design and Distillation Operation (McGraw-Hill); and Distillation Troubleshooting (Wiley) by Henry Kister.

l. Gas Cyclones and Swirl Tubes (2008), 2nd edition, Springer, by A.C. Hoffman and L. Stein.

m. Flow of Fluids Through Valves, Pipes, Pumps and Fittings, Technical Paper No. 410 (2022), CRANE ChemPharma & Energy Corp.

II. Industry Standards and Recommended Practices

The following documents (or latest editions) are industry-recognized standards and recommended practices. They provide recommendations for the design and sizing of separators. The reader should also determine if there are requirements specific to company and local authorities.

a. API RP 12J Process Design of Oil and Gas Separators and Scrubbers (2024), 9th edition.

This recommended practice (RP) is a culmination of the work of a diverse committee of 34 members from operators, engineering firms, and technology suppliers. It provides an excellent summary of separator design and sizing, typical internals, and background information on the basics of separation.

For a summary of API 12J 9th edition contents:

- Riesenberg, J., Grim, L., and Chin, R. (2024) Revision of API 12J: Specification for Oil and Gas Separators, SPE Webinar.

b. GPSA Engineering Data Book, Section 7, 14th edition, GPSA.

Section 7 covers separator design and sizing guidelines similar to those in API 12J RP. Mist-eliminator types (mesh, vanes, cyclones) and their capture mechanisms are discussed. In addition, Section 7 covers filtration and coalescing devices, specialized separators, and water-treating separators. Although we highlight Section 7, the entire Data Book is a valuable resource for your library.

c. NORSOK Standard P-002:2023, Process System Design, Standards Norway.

The NORSOK Standards are developed by the Norwegian oil and gas industry including operators and suppliers. P-002 covers requirements for process piping and equipment for offshore production facilities. Separator design and sizing guidelines are provided with reference to GPSA design rules. Although we highlight P-002, the entire NORSOK Standard is a valuable resource for your library.

d. API Standard 521 (2020), Pressure-Relieving and Depressuring Systems, 7th edition.

Flare knockout drum sizing/design is covered in this sandard as part of the requirements and guidelines regarding causes of overpressure, relieving rates, and disposal systems.

e. API Recommended Practice 14C (2017), Analysis, Design, Installation, and Testing of Safety Systems for Offshore Production Facilities, 8th edition.

This RP has requirements and guidelines for safety systems of pressure vessels.

f. ASME Boiler and Pressure Vessel Code (BPVC), 2023

This code is used for the design and construction of pressure vessels.

III. Articles

The following articles or publications provide a range of information useful for the design and sizing of separators and mist eliminators.

a. Bothamley, M. (2013) Gas/Liquid Separators: Quantifying

Separation Performance , Parts 1, 2, and 3, SPE Oil and Gas Facilities.

The articles are an excellent summary of the design of separators and discuss the droplet methodology to quantify two-phase separator performance (liquid carryover). The articles also have guidelines on mesh, vane, and cyclone capacities.

Additional Reading

For droplet methodology applied to three-phase separators and guidelines on characterizing the impact of droplet shear resulting from pipe fittings:

- Bothamley, M. (2017), Quantifying Oil/Water Separation Performance in Three-Phase Separators Parts 1 and 2, SPE Oil and Gas Facilities.

b. Taitel, Y. and Dukler A.E. (1976), A Model for Predicting Flow Regime Transitions In Horizontal and Near-Horizontal Gas-Liquid Flow, AIChE J., 22(1):47–55.

Inlet piping gas-liquid flow pattern affects the operation of the separator. This article provides an understanding of the different types of two-phase flow patterns in horizontal pipes and the mechanisms for their formation.

Additional Reading

For predicting the different types of flow patterns for three-phase flow in horizontal pipes and understanding the mechanisms for their formation:

- Zhang, H.Q. and Sarica, C. (2006), Unified Modeling of Gas/Oil/Water-Pipe Flow-Basic Approaches and Preliminary Validation, SPE Proj Fac & Const 1 (02):1–7, SPE-95749-PA.

For the effect of flow pattern on separation:

- Heijckers, C. (2012) Flow Conditioning Impact on Separations, SPE Webinar.

For an empirical approach to characterize maldistribution in the inlet piping to a separator:

- Grim, C.L. (2018) A Model for Evaluating Inlet Systems to Gas/Liquid Separators, SPE Oil and Gas Facilities.

c. Ishii, M. and Grolmes, M.A. (1975), Inception Criteria for Droplet Entrainment in Two-phase Concurrent Film Flow, AIChE J., 21(2):308-318.

Entrainment (or re-entrainment) of liquid from a liquid surface is a key factor in determining the maximum gas capacity of mist eliminators such as mesh, vanes, and cyclones as well as the gas space of a horizontal separator. This insightful article provides an excellent discussion of the different methods of droplet formation from a film and provides criteria for the inception of entrainment.

Additional Reading

A simpler criteria that has been used to limit gas velocities to avoid re-entrainment from a liquid surface is the Kelvin-Helmholtz Instability velocity. The analytical equation for this velocity can be found in:

- Chandrasekhar, S. (1961) Hydrodynamic and Hydromagnetic Stability, pp. 481–486, Dover.

d. Walsh, J. (2016) The Effect of Shear on Produced Water Treatment, SPE Oil and Gas Facilities Savvy Separator Series.

Large drop sizes are required for good separation and creating small drops should be avoided. This article provides an overview of how shear through pipes, pumps, and valves for example can affect the size of the drops.

Additional Reading

For a better understanding of oil droplet coalescence:

- Walsh, J. and Frankiewicz, T. (2017) Physical Processes Behind Oil Droplet Coalescence During Water Treatment, SPE Oil and Gas Facilities Savvy Separator Series.

For droplet breakup in a choke valve:

- van der Zande, M.J., Muntinga, J.H., and van den Broek, W.M.G.T. (1998) Emulsification of Production Fluids in the Choke Valve, SPE-49173-MS.

For improving oil-water separation by reducing shear:

- Husveg, T., Husveg, R., van Teeffelen, N., Verwey, R., and Guinee, P. (2022) Reviewing Cyclonic Low-Shear Choke and Control Valve Field Experiences, SPE Prod & Oper 37(01):17–32, SPE-205016-PA.

For an overview of produced water-management in the Gulf of Mexico:

- Walsh, J. and Bansal, K.M. Mastering Produced-Water Management in Deepwater GOM: 25 Years of Insights, Part 1, SPE Oil and Gas Facilities (2024) and Part 2, SPE Oil and Gas Facilities (2025).

e. Nelson, S. (2020), A Century of Carry-Over—0.1 gal/MMscf, SPE Oil and Gas Facilities Savvy Separator Series.

Separators should be designed to achieve a separation performance sufficient to meet the requirements of the downstream processes. Different separators do not require the same level of performance, depending on the application and the equipment downstream. For example, a gas-liquid production separator with a downstream gas scrubber does not need the same liquid separation efficiency as a scrubber protecting a compressor. The 0.1 USG/MMscf liquid carryover specification has been used ubiquitously without regard to the application and is rarely achieved in practice (regardless of performance guarantees). This article provides background information of the origin of the specification and its intended use.

Additional Reading

- Green, S. (2017) Gas/Liquid Scrubber Performance Testing at Field-Like Conditions, GPA Annual Convention, San Antonio, Texas.

This presentation summarizes results showing that the 0.1 USG/MMscf specification was met only in a very small percentage of the tests.

f. Austrheim,T., Gjertsen, L.H., and Hoffman, A.C. (2007), Is the Souders–Brown Equation Sufficient for Scrubber Design? An Experimental Investigation at Elevated Pressure With Hydrocarbon Fluids, Chemical Engineering Science, 62(21):5715-5727.

A large amount of data is available on the testing of internals with air-water. This paper provides a summary of various experiments performed on separators looking at how the physical properties impacted the capacities and the validity of the normal design rules for a wide range of systems, with relevant performance data.

Additional Reading

For overview of mist removal options:

- Fabian, P, Cusack, R., Hennessey, P, and Neuman, M. (1993) Demystifying the Selection of Mist Eliminators, Part 1: The Basics, and Part 2: The Applications, Chemical Engineering.

For discussion of vane type mist eliminators:

- Dries, H.W. and Hoffman, A.C. (2019) A Correlation Giving Improved Description of the Capacity and Efficiency of Vane-Type Gas-Liquid Separators, AIChE J., 65(5):e16566.

For discussion of axial cyclone type mist eliminators:

- Swanborn, R. (1988) A New Approach to the Design Of Gas-Liquid Separators for the Oil Industry, Thesis, Delft University.

- Austrheim, T. (2006) Experimental Characterization of High-Pressure Natural Gas Scrubbers, Thesis, University of Bergen.

For discussion of mesh-type mist eliminators:

- Flegiel, F., Windmeier, C., Wiezorek, M., Döß, A., Schubert, M., Hampel, U., and Schleicher, E. (2021) Capacity and Sizing of Wire Mesh Mist Eliminators at Critical Fluid Properties, Chemie Ingenieur Technik, 93(7), p. 1166-1177.

- Grim, C.L. and Al-Zubail, A. (2023) A Complete Model for Mesh Pad Mist Eliminators in Oil and Gas Processing by Analogy With Distillation Packing, SPE Prod & Oper 38(02):332–349.

g. Rawlings, C.H. (2013) Sand Management Methodologies For Sustained Facilities Operations, SPE Oil and Gas Facilities.

Sand is typically produced with the hydrocarbon fluids and must be handled in order to maintain facility operations. The sand can damage equipment and impede separation. This article provides an overview of wellhead/surface facilities for sand separation and management.

Additional Reading

- Rawlings, C.H. and Wang, I.I. (2001) Design and Installation of a Sand-Separation and -Handling System for a Gulf of Mexico Oil Production Facility, SPE Production and Operations 16(03):134-140, SPE-72999-PA.

IV. Parameters

The following parameters are often used in equations for the sizing of separators and internals.

a. Reynolds Number, Re

This dimensionless parameter is a ratio of inertial and viscous forces and is used to determine fluid flow regimes, e.g., laminar or turbulent.

where

ρ – fluid density (kg/m3)

V – fluid velocity (m/s)

L – characteristic length scale (m)

µ – fluid dynamic viscosity (kg/m-s).

Particle drag coefficients, pipe frictional losses, and entrainment velocities, for example, depend upon the Reynolds number.

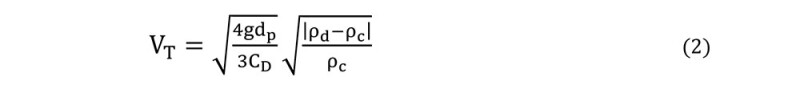

b. Terminal Velocity, VT / K-Factor, K

This equation is used to determine the maximum allowable velocity in gravity-dominated systems.

where

VT – particle terminal velocity (m/s)

CD – drag coefficient of particle (dimensionless, function of Re)

ρc – continuous phase density (kg/m3)

ρd – particle density (kg/m3)

g – gravitational constant (m/s2)

dp – particle diameter (m)

As an example, for a liquid drop of diameter dp in a gas flow, the maximum vertical gas velocity should be less than VT in order for the drop to settle out.

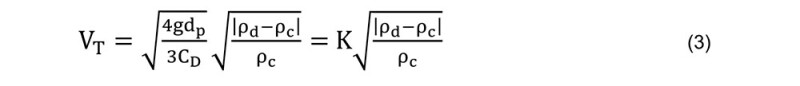

The first term on the righthand side of equation 2 is often lumped into a single parameter K as:

This equation is often used to size vessel gas space and mist eliminators such as mesh pads and vane packs. The K factor is per technology supplier.

For additional reading on the original application and equation derivation:

- Souders, M and Brown, G.G. (1934), Design of Fractionating Columns, I. Entrainment and Capacity, Industrial & Engineering Chemistry, 26 (1): 98–103.

See also previously cited API RP 12J reference.

c. Weber Number, We

The dimensionless Weber number is the balance of inertial forces and surface tension forces and is a primary factor in determining critical droplet sizes. For liquid drops in a gas phase, We is defined as:

where

ρg – gas density (kg/m3)

Vg – gas velocity (m/s);

σ – interfacial tension (N/m)

d – liquid drop size (m)

For example, one correlation for minimum drop size is We = 8.

For additional reading on We, drop sizes, and distributions:

- Hinze, J.O. 1955. Fundamentals of the Hydrodynamic Mechanism of Splitting in Dispersion Processes, AIChE J., 1(3):289–295.

- Brauner, N. (2001) The Prediction of Dispersed Flows Boundaries in Liquid–Liquid and Gas–Liquid Systems, International J. of Multiphase Flow, 27(5):885–910.

- Kouba, G. (2014) Predicting Droplet Size Distribution, SPE Webinar.

d. Momentum Flux, M

This parameter, M, is the momentum flux per unit volume of the fluid and has units of pressure (Pa). It is a term (or one that is divided by 2) used in calculating drag force, pipe and fitting losses, nozzle losses, and losses through separator internals such as a mesh pad. It is often used as a design parameter for inlet nozzle and inlet device sizing. M is defined as:

where

ρ – fluid density (kg/m3)

V – fluid velocity (m/s).

and the fluid can refer to a single phase or a mixture depending upon the application.

For example, a half-open pipe inlet is limited to a mixture ρV2 of ~1,500 Pa while an inlet vane device has a range of ~6,000 to 10,000 Pa.

Refer to API 12J RP and Bothamley articles previously cited.

e. Froude Number, Fr

This dimensionless number is the ratio of gravitation forces and inertial forces. It is useful in separators where liquids are flowing into nozzles, indicating the likelihood of entraining gas and vortexing. It is also used for sizing downcomer pipes for self-venting flows. Fr is defined as:

where

V – nozzle/pipe velocity (m/s)

g – gravitational acceleration (m/s2)

ρl – liquid density (kg/m3)

ρg – gas density (kg/m3)

d – nozzle/pipe diameter (m)

For example, a typical design criteria for self-venting flow is Fr < 0.3.

Additional reading (including vortex breaker designs):

- Simpson, L. (1968), Sizing Piping for Process Plants, Chem. Engineering, pp. 192–214.

- Rochelle, S.G. and Briscoe Jr., M.T. (2010) Predict and Prevent Air Entrainment in Draining Tanks, Chem. Engineering, pp. 37-43.

- IOGP S-619, Specification for Unfired, Fusion Welded Pressure Vessels—Version 2.0, 2022, Appendix J Standard drawings (J.1 and J.2 on vortex breakers, J.15 on outlet strainers).

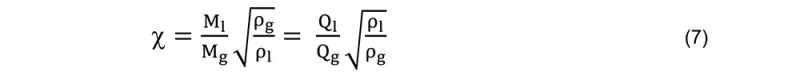

f. Flow parameter, χ

where

Ml – liquid mass rate (kg/s)

Mg – gas mass rate (kg/s)

Ql – liquid flow rate (m3/s)

Qg – gas flow rate (m3/s)

ρl – liquid density (kg/m3)

ρg – gas density (kg/m3)

This parameter has been used to characterize the liquid feed into the vessel or the liquid load approaching the mist eliminator, to correlate tower flooding velocities, and to correct multiphase meters. Others may use the symbol Φ for this parameter.

Additional Reading

- York, O.H. and Popple, E.W. (1963) Wire-Mesh Mist Eliminators, Chem Engineering Progress, 59 (6).

- Sherwood, T.K., Shipley, G.H., and Holloway, F.A.L. (1938) Flooding Velocities in Packed Columns, Industrial and Engineering Chemistry, 30(7):765–769.

g. Crest Height

Weirs are typically used in three-phase horizontal separators to facilitate the removal of oil and water. In the spillover weir, the crest height should be accounted for in the design. For a horizontal weir that spans the vessel (no end corrections), the Francis equation can be used to calculate the crest height (for a rectangular sharp crested weir).

where

Q – flow rate (m3/sec,)

L – length of the weir (m)

H – crest height (m)

Perry’s Chemical Engineering Handbook cited previously discusses other types of weirs.

Additional Reading

- Francis, J.B. (1883), Lowell Hydraulic Experiments, 4th edition, D. Van Nostrand.

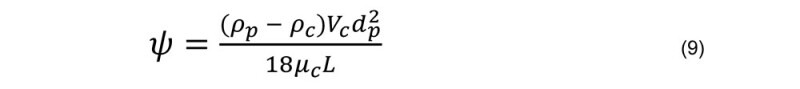

h. Inertial Parameter, ψ

Defined in equation 9 below, the dimensionless inertial parameter ψ is used to evaluate separation performance of inertial separation systems such as mesh pad and vane type mist eliminators. Note: There are slightly different variations of this parameter depending upon the definition of L and whether continuous phase density can be ignored with respect to the drop density.

The parameter (also referred to as impaction parameter) is a ratio of the drop momentum response time to the continuous fluid system time. (It can also be thought of as the ratio of the drop stopping distance to a characteristic length of the target collector, e.g., wire). For ψ >> 1 (long drop response time compared to that of the flow), the more likely the drop will impact the target. Then for ψ << 1 (short drop response time compared to that of the flow), the more likely the drop will follow the fluid streamlines and not impact the target.

where

ρp – droplet density (kg/m3)

ρc – continuous phase density (kg/m3)

dp – droplet diameter (m)

Vc – continuous phase velocity (m/s)

μc – continuous phase viscosity (kg/m-s)

L – characteristic length of the target collector (m).

This parameter is used, for example, to determine a droplet impaction efficiency of a wire mesh.

Additional Reading

- Carpenter, C. L. and Othmer, D. F. (1955) Entrainment Removal by a Wire-Mesh Separator, AiChE J., 1(4), p. 549-557.

- Crowe, C.T., Schwarzkopf, J.D., Sommerfeld, M., and Tsuji, Y. (2012) Multiphase Flows With Droplets and Particles, 2nd edition, CRC Press.

Refer also to Burkholz and Hoffman/Stein books previously cited.

i. Peclet Number, Pe

This parameter is the ratio of the rate of advection to the rate of diffusion. It is used to evaluate separation performance of diffusion separation systems such as filter coalescers.

where

Vs – superficial velocity through media bed (m/s)

dt – characteristic length of the deposition target (m)

D – diffusion coefficient (m2/s)

Additional Reading

- Mead-Hunter, R., King, A.J.C., and Mullins, B.J. (2014) Aerosol-Mist Coalescing Filters–a Review, Separation and Purification Technology, 133:484–506.

V. Advancements

Designing, debottlenecking, and troubleshooting separators have become more robust with the following advancements.

a. CFD (computational fluid dynamics)

CFD arguably has been the most important tool that has improved separator design and troubleshooting. CFD and the accompanying computer-aided design (CAD) and computer-aided engineering (CAE) have advanced to the point where changes in designs can be tested. However, be aware that CFD is a tool, but the quality of the model, assumptions, and equations impact the results and proper interpretation of the CFD results is essential.

CFD has been used to design, for example, swirl elements in cyclonic mist eliminators and inline separators. In addition to the design of the internals themselves, CFD had been used extensively to model:

- Multiphase fluid flow in inlet piping

- Flow distribution and separation within the vessel

- Liquid sloshing in separators

- Droplet tracking

- Solids settling

- Effect of slugging on separator level control

CFD in conjunction with analytical models can be used to predict drop size and to modify the internals or flow distribution to minimize droplet shearing.

Additional Reading

- Rhyne, L. and Gandhir, A. (2015) CFD Optimization of Scrubber Inlet Design, SPE Webinar.

- Read, A. (2017) Introduction to CFD for Separator Design, SPE Oil and Gas Facilities Savvy Separator Series.

See also Heijckers webinar previously cited.

b. Test facilities with realistic fluids

Testing of internals has primarily been with air/water. In order to have designs more quickly accepted by end users and to validate models, significant funds by both vendors and operators (e.g. Equinor K-lab, ProLabNL, SwRI, FRI, IFPEN) were expended to develop testing facilities that could operate with realistic pressures and fluids whose properties were more akin to the actual operating ones.

Additional Reading

- Bymaster, A., Olson, M., Grave, E., Svedeman, S.J., Viana, F., Akdim, M.R., Mikkelsen, R. (2011) High Pressure Gas-Liquid Separation: An Experimental Study on Separator Performance of Natural Gas Streams at Elevated Pressures, OTC 21781-MS.

- Kvamsdal, D., Carlson, F., and Talseth, M. (2012) High-Pressure Gas Liquid Separation, Experimental Verification of Separator Internals in Laboratory and Real Fluid Systems, OTC-23306-MS.

- Grave, E. and Olson, M. (2014) Design and Performance Testing of an Integrated, Subsea Compact Separation System for Deepwater Applications Design, SPE Oil and Gas Facilities.

c. Droplet distribution, tracking and capture modeling

Separator sizing and performance estimation using droplet modeling have advanced with predictions of droplet distributions to complement existing droplet capture models of internals. In addition, multiphase CFD models are being advanced by accounting for effects of drop coalescence, shearing, and impact.

Additional Reading

- Calvert, S., Jashnani, I.L., Yung, S., and Stalberg, S. (1974) Entrainment Separators for Scrubbers: Initial Report, EPS-650/2-74-119-a.

- Kataoka, I., Ishii, M. and Mishima, K. (1983) Generation and Size Distribution of Droplet in Annular Two-Phase Flow, ASME J. Fluids Eng., 105(2):230-238.

- Pan, L. and Hanratty, T.J. (2001) Correlation of Entrainment for Annular Flow in Pipes, Int. J. of Multiphase flow, 28(3):385-408.

- Viana, F. (2017) Liquid Entrainment in Gas at High Pressures, Thesis, University of Tulsa. If you cannot access the thesis, these two papers have similar information:

- Viana, F., Mantilla, I., Mohan, R., and Shoham O. (2016) Liquid Entrainment in Gas at High Pressure–Part 1: Experimental Approach and Initial Testing, BHR-2016-367.

- Viana, F., Mohan, R., and Shoham O. (2018) Liquid Entrainment in Gas at High Pressure–Part 2: Experimental Data and Model Improvement, BHR-2018-097.

- Oshinowo, L.M. and Vilagines, R.D. (2020) Modeling of Oil–Water Separation Efficiency in Three-Phase Separators: Effect of Emulsion Rheology and Droplet Size Distribution, Chem. Eng. Research and Design, 159:278–290.

- Kouba, G. (2003) Mechanistic Models for Droplet Formation and Breakup, ASME Proceedings, 4th ASME-JSME Joint Fluids Engineering Conference, FEDSM2003-45542.

See also Bothamley articles and Burkhotz reference previously cited.

d. Dispersion band model for oil-water separation

Oil-water separation has been modeled by some variation of droplet settling. For example, an oil droplet must rise to the interface before reaching the water outlet or a water droplet settling to the interface before reaching the weir/oil outlet. However, this implies low concentrations of the dispersed phase where droplets are not hindered by other droplets (impeding settling) as well as rapid coalescence (nonlimiting coalescence kinetics). Dispersion band theory is primarily occupied with describing the limiting coalescence kinetics, which becomes prominent as the dispersed phase concentration (e.g., water cut) increases. It treats the settling region as a continuous phase and describes its behavior on a macroscopic basis. Modeling the dynamics of the dispersion band leads to a relationship between throughput and dispersion band height.

For a more detailed description of dispersion band modeling:

- Polderman, H.G., Bouma, J.S., and van der Poel, H. (1997) Design Rules for Dehydration Tanks and Separator Vessels, SPE-38816-MS.

Additional Reading

- Jeelani, S.A. and Hartland, S. (1993) The Continuous Separation of Liquid/Liquid Dispersion, Chem. Eng. Sci., 48(2):239–254.

- Arntzen, R. (2001) Gravity Separator Revamping, Thesis, Norwegian University of Science and Technology, Trondheim, Norway.

- Pereyra, E., Mohan, R., and Shoham, O. (2013) A Simplified Mechanistic Model for an Oil/Water Horizontal Pipe Separator, SPE Oil and Gas Facilities.

See also Oshinowo article cited previously.

e. Inline separators

Although inline separators have been around for a long time, their designs have been advanced and have become more acceptable in offshore applications but are not mainstream. Their major use has been in debottlenecking existing separators, subsea applications, or as small stand-alone systems. The inlines are used as scrubbers (high gas/oil ratio [GOR]), degassers (low GOR), flow splitters (in between low and high GOR), de-waterers (water continuous oil-water), and desanders. The majority of the applications are for scrubbing. There have also been some inline electrostatic liquid coalescers.

Additional Reading

- Sarshar, M.M. and Beg, N.A. (2001) The Applications and Performance of a Novel Compact Separator in the Oil and Gas Industry, 2nd GCC-EU Advanced Oil and Gas Technology Conference, Abu Dhabi, UAE.

- Knudsen, B., Bjorkhaug, M., Johannesen, B., Ottoy, M., Eidsmo, G.S., and Bruun, T. (2010) Field Test of Compact Cyclonic Technology for Separation of Gas/Liquid and Oil/Water at the Gullfaks Field, OTC-20748-MS.

- Schook, R. and Thierens, D. (2011) De-Bottlenecking of Mature Field Production Through the Use of Very Compact and Efficient Separation Equipment, Topside Or Subsea, OTC-21617-MS.

- Hannisdal, A., Westra, R., Akdim, M.R., Bymaster, A., Grave, E., and Teng, D. (2012) Compact Separation Technologies and Their Applicability for Subsea Field Development in Deep Water, OTC-23223-MS.

See also Grave and Olson article cited previously.

f. Electrostatic treaters

Removing small drops of water from oil or even large drops in viscous oils is made easier using electrostatic treaters. These employ AC and/or DC electrical fields to induce droplet motion and to promote coalescence. They are used extensively as the final oil-polishing stage as well as for desalting.

For an excellent overview of electrostatic treating:

- Sams, G. (2016) Electrostatic Dehydration and Desalting: Essential Processes for Reducing Corrosion During Transportation and Refining Process, SPE Webinar.

g. Diagnostic tools

Troubleshooting separation problems has been made easier with nucleonic technology such as gamma scans, neutron back scatter, and radioactive tracers, etc. The external scans provide information on solids and liquid levels as well as dislocated internals. Tracers supply information on retention time/short-circuiting. Internal density profilers provide continuous monitoring of the gas-oil-water-solids levels in a vessel.

For more information on diagnostic tools including nucleonic and tracer methods:

- Shaw, A. (2014) Troubleshooting Separation Challenges Using Online Diagnostics, SPE Webinar.

- Smith G. (2017) Operational Troubleshooting of Separators, SPE Oil and Gas Facilities Savvy Separator Series, and Smith G. (2022) Operational Troubleshooting of Separators, SPE Webinar.

h. Subsea processing

Deepwater reservoirs resulted in development of innovative subsea processing systems. The systems range from simple gas-liquid separators to complete three-phase separation with boosting and water reinjection. In general, subsea processing is still a one-off application that many separation practitioners may never see. Nonetheless, separation know-how has advanced over the past 15 years or so because of the research, testing, and qualification around subsea processing.

For more information on various subsea processing projects:

- do Vale, O.R., Garcia, J.E. and Villa,M. (2002) VASPS Installation and Operation at Campos Basin, OTC-14003-MS.

- Horn, T., Bakke, W., and Eriksen, G. (2003) Experience in Separation and Water Injection Station at Troll Oil Field in the North Sea, OTC-15172-MS.

- Bon, L. (2009) Pazflor, A World Technology First in Deep Offshore Development, SPE-123787-MS.

- de Oliveira, D. A. et al (2013) Commissioning and Startup of Subsea Marlim Oil and Water Separation System, OTC Brazil, OTC-24533-MS.

- Kristiansen, O., Sørensen, Ø., and Nilssen, O.R. (2016), CompactSep–Compact Subsea Gas-Liquid Separator for High-Pressure Wellstream Boosting, OTC-27156-MS.

VI. Lessons learned

Throughout our careers, we have had some lessons learned passed on to us from our mentors, perhaps found out the hard way, or developed as good practice. In any case, the lessons learned below are neither exhaustive and may seem obvious. However, even for the experienced, the list can be thought- provoking.

a. Safety.

Your number one priority is to protect people and the environment. Double check your design.

Provide the appropriate operations training to the operators. This is above and beyond the “principle of operation” training that component vendors provide. Look to have a thorough “system” training program developed and be sure and include cause-and-effect sections for troubleshooting purposes.

Adhere to a strict routine maintenance program. Quite often the simplest things can manifest into major upsets. Clean/repair/replace, as needed, items such as chemical-injection pumps, flowmeters, level/interface controllers, solids accumulation, and plugged sample ports to avoid having a very simple routine fix developing into a major upset and ultimate shutdown.

b. Understand the fluid outlet requirements within a systemwide perspective.

Don't accept a design specification rule because "that's how it's always been." The 0.1 USG/MMscf is a good example. What does the downstream equipment actually require, what is the impact on the downstream process of more water in the oil or more oil in the water? Separators should be designed to achieve a separation performance sufficient to meet the requirements of the downstream processes.

Refer to the Nelson article and API 12J RP cited previously.

c. Make sure you have the correct fluid properties for design and the life of field operating envelope.

Do the fluid properties make sense? Does a 16 kg/m3 gas density make sense at 100 bar? Does the simulator output make sense especially for surface tensions or oil viscosities? If the data sheet specifies two phases (gas and liquid), make sure that there are only two (and they haven’t combined the real liquids into a pseudo-phase).

Do you have the design operating envelope over the life of the field? Getting the design basis right—and including Startup, Shutdown, Blowdown, Early-Mid-Late Life Operations, Alternate operating cases, etc.—all impact the design and can be used to determine the real operating envelope needed. Remember to include water cut and compositional changes expected over the life of the operating facility.

Additional Reading

- Norgaard, H. and Nygaard, L. (2014) Measurement and Calculation of Surface Tension of Oil, Gas, and Glycol, Thesis, NTNU-Trondheim.

- Chin, R. W. et al (2016) The Ghosts of Separators Past, Present, and Future, SPE Oil and Gas Facilities Savvy Separator Series.

See also Campbell Vol.1 and McCain books previously referenced.

d. Understand effects on fluid properties with mixing of different chemicals, oilfield contaminants, and oils.

Chemicals can change the fluid properties of the hydrocarbon fluids and can adversely affect the phase separation. Some well workover fluids can cause foaming and emulsion issues. Compatibility of added chemicals with each other and the hydrocarbon fluids including fines should be addressed. For example, injection of kinetic hydrate inhibitor into incompatible water can result in solids precipitation. Mixing of different oils can lead to precipitation of asphaltenes.

Additional Reading

- Hebert, P.B., Khatib, Z.I., Norman, W.D., Acock, A., and Johnson, M. (1996) Novel Filtration Eliminates System Upset Following Acid Stimulation Treatment, SPE 36601-MS.

- Matar, O.K. (2013) Defoaming Additives in Horizontal Multiphase Flow—Impact on Flow Regime and Separations, SPE Webinar.

e. Avoid recycles.

Fluid recycle streams typically contain constituents such as solids, asphaltenes, chemicals that can create emulsions and significantly affect separation. Process the recycle streams separately if possible. Don’t recycle rag layers or wet-oil back to the front of the production train. Have a separate “bad”-oil- treating train. Rag layers will build up over time at the oil/water interface. Plus, you may be mixing chemicals from the water-treating process into the oil that can have adverse effects. Too much chemical can itself cause a rag layer. See previous item (d) on chemical contaminants.

For design considerations on handling some recycle streams:

- Frankiewicz, T and Walsh, J. (2010) Treating Produced Water on Deepwater Platforms: Developing Effective Practices Based Upon Lessons Learned, ATCE Florence, SPE 134505-MS.

For an example of recycle issues, see Lesson 2 in:

- Chin, R.W. (2018) 5 Lessons To Simplify Separator Troubleshooting, SPE Oil and Gas Facilities Savvy Separator Series, August.

f. Visit the facility and talk to operations (before design as well).

Get out of the office! Take any opportunity to visit the site to get firsthand knowledge of the operations. Field personnel have a wealth of knowledge and experience that can help you design and troubleshoot process equipment. Understanding their viewpoint will improve your relationship with them and allow you to get things done jointly.

Go and look at the equipment. Is the instrumentation properly installed (don‘t believe electronic signals). Make sure level instruments are calibrated.

“Walk the line”—In the field, walk along the pipes feeding and exiting the separator. Verify they match the piping isometrics. Check for pockets, location of valves, instrumentation, elbows or other connections that may be surprisingly introduced. Piping isometrics may not be available or up to date.

For an example of an instrument issue, see Lesson 5 in Chin article cited above in item e, “Avoid Recycles.”

g. Don’t always blame the separator or internals.

Poor separation performance is typically blamed on the separator itself with the main target being the internals. However, after an analysis of the issues, the root cause is often found to be a failure in areas related to the separator/internals. Shortcomings in design, installation, instrumentation, and operation can lead to poor separator performance.

Additional Reading

- Chin, R. W. (2024) Are the Separators Really at Fault? Part 1: Design, SPE Oil and Gas Facilities Savvy Separator Series.

- Chin, R. W. and Turkey, M. (2024) Are the Separators Really at Fault? Part 2: Installation, SPE Oil and Gas Facilities Savvy Separator Series.

- Chin, R. W. and Riesenberg, J. (2024) Are the Separators Really at Fault? Part 3: Instrumentation and Operations, SPE Oil and Gas Facilities Savvy Separator Series.

VII. Capability Gaps

Over the years, technologies have been developed that have improved and expanded the capabilities of separators. While the technologies and techniques continue to develop, there are gaps in what we can and what we would like to do. The authors have noted some areas that would be useful “If they only had.”

- Better droplet shearing prediction through valves/elbows in liquid/gas and liquid/liquid systems

- Better availability/sharing of test data with a) low surface tension, b) high pressure, and c) high viscosity

- A “perfected” dispersion band theory

- More field operating data

- More joint-industry cooperation in testing/modeling for separation (along the lines of HTRI, FRI)

- Online liquid in gas carryover meter/instrument

- Online measurement of water droplet in oil flow

- A Superman X-ray vision-type instrument to see what is going on throughout the vessel and the process

VIII. Closing Remarks

This article contains a wealth of information concerning a wide range of separator topics. A truly savvy separator engineer will take this information and use it to improve designs, operate, and troubleshoot existing equipment, and hopefully, enhance the state of the art.

As the tools and techniques become more sophisticated, it can be easy to trust the easy answer and avoid delving into the details.

So, just remember the following, statements from the SPE Separator Design and Troubleshooting training course, with the last one specifically attributed to our fellow Savvy Separator Victor van Asperen.

- There is no perfect model or computer program to design the perfect separator.

- Relying on correlations or computer programs without understanding the real separation phenomena is dangerous.

- Understand the limits of the correlations and datasets. Are you interpolating or extrapolating? What does this tell you about the uncertainty?

- Engineering is about recognizing, quantifying, and dealing with the uncertainty of the data and models you are using and coming up with a design that will work despite the uncertainties.

Acknowledgments

The authors thank fellow Separations Technology Technical Section members Victor van Asperen, Shabbir Husain, Lanre Oshinowo, and Federico Gayoso for their valuable review of this article as well as all the authors and reviewers of the prior Savvy Separator articles. We also express our most wholehearted gratitude to SPE’s Pam Boschee, Director, Magazines, for her invaluable support and editing of the series.

Robert (Bob) Chin, PhD, PE is co-founder of Padden Engineering LLC. He has been providing fluid flow/process services to the petrochemical industry for over 40 years, specializing in multiphase flow, pipeline leak detection, heavy-oil dehydration, and oil/gas separation. Chin co-founded SPE’s global Separations Technology Technical Section, and was its initial chair from 2011 to 2013. He is the originator, a primary author, and editor for SPE’s Savvy Separator Series of articles in the Oil and Gas Facilities magazine. He co-developed SPE’s 2-day training class on separations. Most recently, he developed the SPE’s Savvy Separator Educational Video Series 10-part video series as well as the ShopTalk series.

Logan Grim is a senior oil process engineer at Aramco, based in Dhahran, Saudi Arabia. He graduated with a master’s of engineer from Imperial College London in 2008. He started his career with the engineering contractor Foster Wheeler, now Wood, where he worked on the process design and construction of refining, petrochemical, LNG, and upstream facilities before moving into process systems engineer.

In 2019, Grim joined Aramco in Saudi Arabia work as an oil processing engineer, as part of Aramco’s central engineering services organization. In this role he is responsible for the process aspects of capital projects, operational troubleshooting, and consultation for oil facilities across Saudi Arabia.

In these roles, he has developed numerous applications for equipment sizing and rating and physical property prediction. He is a chartered member of the IChemE and was chairman of the SPE Separations Technology Technical Section from 2020 to 2023.

C.L. Grim (https://orcid.org/0000-0001-8092-8615).

Jimmie Riesenberg (MS/BS chemical engineering, Drexel University) is retired from Chevron Corp. after 34 years in process facilities engineering with Texaco and Chevron. He is the chair for the API 12J Separations Committee and was a coauthor of the GSPA Engineering Data Book Section 7–Separations. He was the Chevron separations lead, including lead author for the Chevron Separations Design Guideline and lead design assurance engineer for separator design. He was a past chair for the SPE Separations Technology Technical Section, and Technical Advisory Committee chair for the STAR (Separation Technology Research Program) JIP.

Ed Grave earned his master of science from New Jersey Institute of Technology in 1982. He started at Lummus Technical Center on petrochemical projects, then joined Mobil Research & Development in 1990 as a mass transfer specialist. Retiring from ExxonMobil in 2017, he was the upstream senior technical advisor for fractionation and separation. His team handled research, design, training, and troubleshooting for ExxonMobil's fractionating and separation systems. Grave received a Lifetime Achievement award in 2015 for Innovation and Creativity Excellence, particularly for developing cMIST™ technology.

He led the Separations Technology Research (STAR) Program and served as vice-chair at SPE’s Separations Technology Technical Section. From 2016 to 2017, Grave was an SPE Distinguished Lecturer. He also represented ExxonMobil at Fractionation Research Inc. for more than 20 years, contributing to distillation technology through the Design Practices and Executive Committees.