The Offshore Technology Conference (OTC) selected 12 new technologies for its 2020 Spotlight on New Technology Awards. The annual awards program recognizes innovative technologies and allows companies to showcase the latest advances in offshore exploration and production.

AWARD RECIPIENTS (listed alphabetically by company)

Advisian Digital

CAROL Unloading Robot

CAROL is Worley’s catalyst unloading robot for offshore, liquefied-natural-gas, gas-plant, and refinery vessels. CAROL effectively replaces the requirement to have a human inside the vessel during catalyst vacuuming operations. Human safety is improved by a factor of 10, and efficiency is improved by at least 20%.

Baker Hughes

Aptara Lightweight Compact Tree

The Aptara lightweight compact tree adapts to changing needs through the entire life of field. With a significantly reduced footprint compared with those of traditional deepwater trees, the tree weighs 50% less and has the potential to reduce capital and operational expenditure by more than 50%.

SureCONNECT Intelligent Wet-Mate System

The modular SureCONNECT intelligent wet-mate system enables connection and reconnection of upper completion components to the lower completion with hydraulic, electric, or fiber-optic lines. Operators can achieve real-time, interventionless monitoring and control across the wellbore, enabling data-driven decisions to optimize performance and mitigate risks proactively.

Bosch Rexroth

Subsea Valve Actuator

During the qualification of its novel Subsea Valve Actuator for Technology Readiness Level 4 with pressure-chamber tests, Bosch Rexroth demonstrated the technology’s capability to provide high actuation forces with limited electric power supply. This enables the implementation of an all-subsea factory in brownfields using the Subsea Instrumentation Interface Standard.

Dril-Quip

VXTe Vertical Subsea Tree System

The VXTe vertical subsea tree system empowers smarter, faster, and safer work, and permanently reduces cost. Installing the nonoriented tubing hanger into the wellhead enables drilling and completions in a single campaign, eliminating blowout-preventer trips. The self-aligning system uses conventional couplers and can be installed at any desired orientation.

Halliburton

Xaminer Magnetic Resonance Service

Halliburton offers the world’s first ultrahigh-pressure, 35,000-psi-rated magnetic resonance sensor for wireline—the Xaminer Magnetic Resonance (XMR) service. The XMR service provides a “Revolution in Resolution” for formation evaluation. The service is focused on the future of NMR wireline logging for deepwater, unconventional, and mature assets.

NOV

PowerBlade Energy Recovery System

The PowerBlade energy recovery system receives, stores, and provides regenerated energy based on operation (e.g., it regenerates energy from heave compensation). Furthermore, it reduces power peaks that can affect the generators and possible power bottlenecks, thereby reducing fuel consumption, improving environmental footprint, and boosting equipment performance.

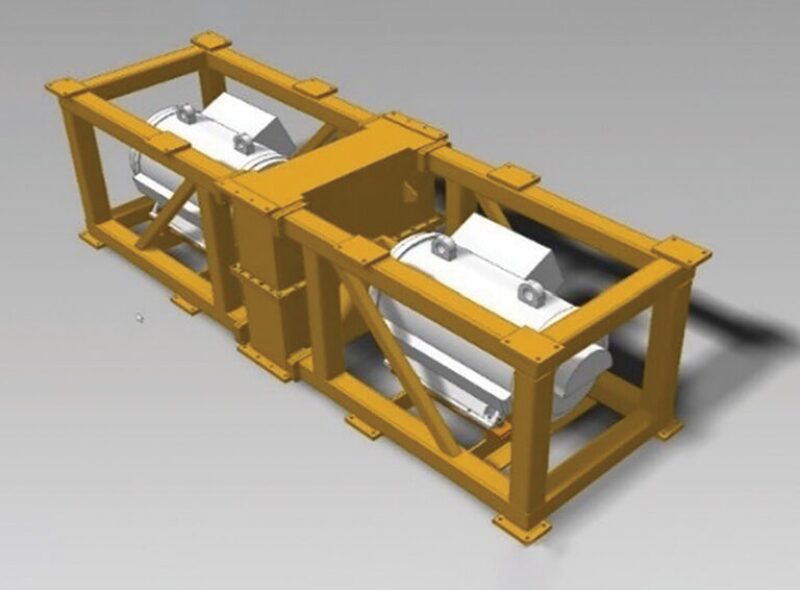

SWIT Sulfate-Removal System

The SWIT system is the world’s first full-scale sulfate-removal and low-salinity plant, designed for long-term continuous operation at the seabed for improved oil-recovery purposes. By employing unique, proprietary technology in combination with process simplifications in this configuration, the system can operate for more than 30 months maintenance free.

Schlumberger

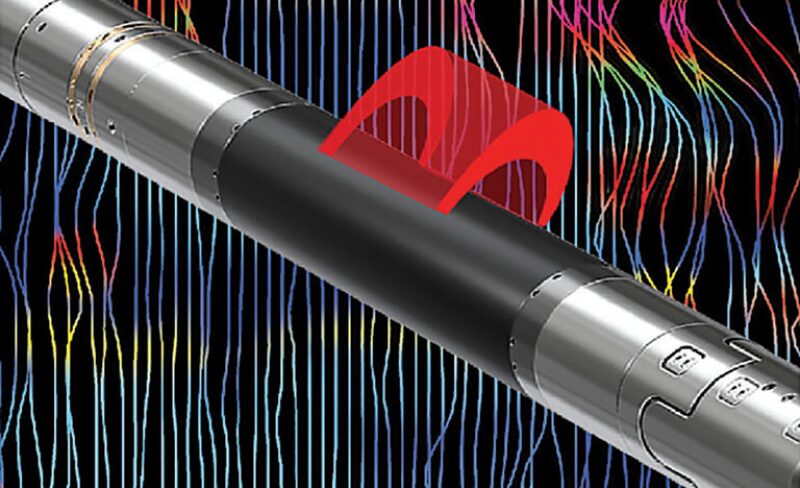

NeoSteer At-Bit Steerable System

The NeoSteer at-bit steerable system is a directional-drilling innovation that integrates the cutting structure with the steering system and can eliminate bottomhole-assembly reconfigurations between curve and lateral sections. The system is capable of drilling both high-dogleg-severity curve sections and straighter higher-quality lateral sections at high performance in a single run.

Ora Intelligent Wireline Formation-Testing Platform

The Ora intelligent wireline formation-testing platform integrates new downhole digital hardware and cloud-native software. With Ora, operators can efficiently evaluate their reservoirs—even in previously inaccessible conditions—and all information is provided in context, in real time, for making confident decisions faster.

Siemens

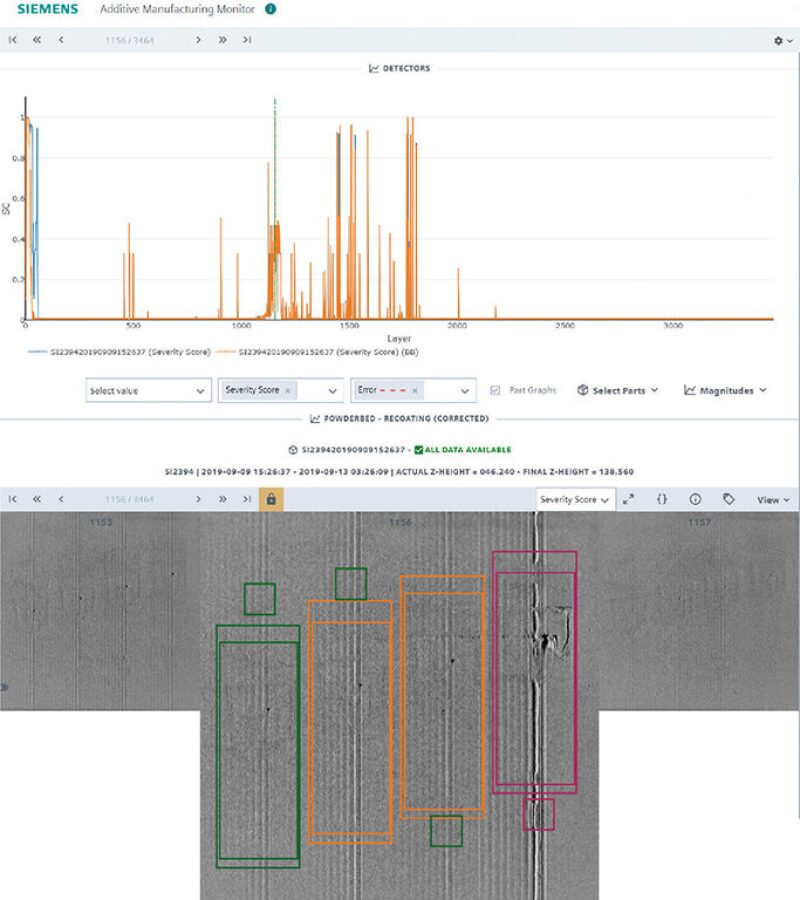

AM Monitor Technology

The AM Monitor stands apart from other monitoring technologies in its use of machine-learning algorithms to impartially evaluate the recoating during the printing of a 3D-printed component, with a speed and accuracy that cannot be matched by humans.

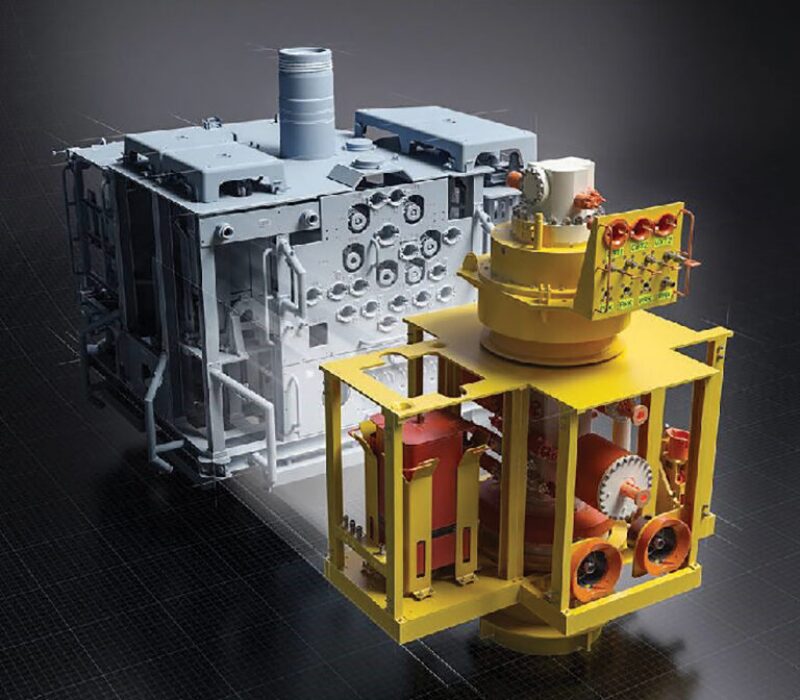

TechnipFMC

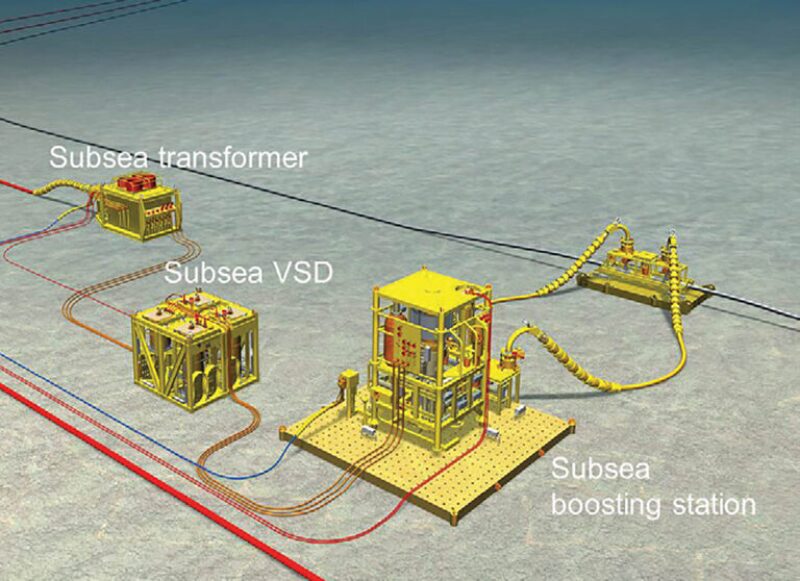

Subsea Power Distribution Station

TechnipFMC’s new Subsea Power Distribution Station eliminates topside expansion needs, reducing subsea boosting costs for brownfield projects. The station comprises a subsea transformer and subsea variable-speed drive, which uses a field-proven WEG VSD, a power transmission umbilical, and connectors. Together, field installation, stepout wells, and field expansions are simplified.

SMALL BUSINESS AWARD RECIPIENTS

DarkVision

HADES-F Downhole Imaging Technology

HADES-F technology uses a next-generation high-resolution acoustic imaging head mounted on an articulating remotely controlled robotic arm. The tool provides submillimetric measurements, images, and 3D reconstructions of any wellbore obstruction, wellhead, fish, or connection. These data are sent to surface in real time from any orientation, regardless of fluid clarity.

Rocsole

LITI Scanning Service

The LITI (Liquid In-Tank Inspection) solution is used to improve the performance of crude-oil operational tanks. Detailed imaging of the emulsion layer can be combined with artificial-intelligence-based prediction tools, leading to improved oil quality for higher revenues at lower cost and faster return in investment.

Rolloos

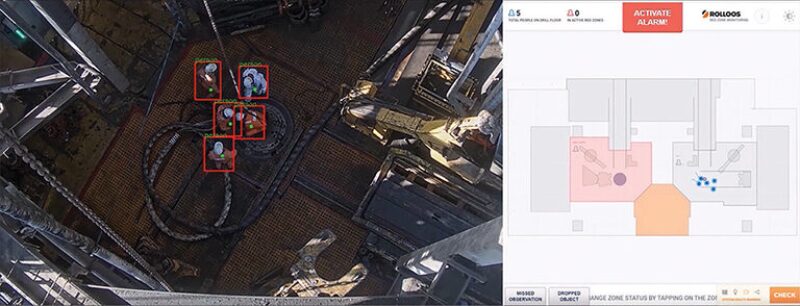

Red Zone Service

Personnel on drilling floors are exposed to the risk of being in the line of fire or being caught between machines. The Red Zone Service keeps people safe and optimizes performance by combining advanced computer vision, artificial intelligence, human/machine integration, and classic change-management strategies.

WFS Technologies

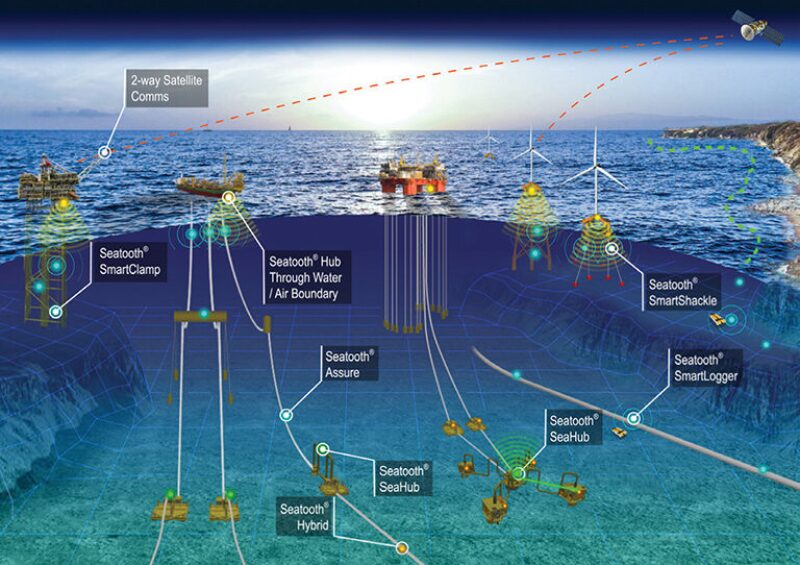

Seatooth SmartClamp Structural Monitoring System

The Seatooth SmartClamp is a smart wireless subsea structural monitoring system that measures strain, acceleration, pressure, and temperature, and uses edge computing to calibrate fatigue models with real-time data at the sensor level. Proprietary subsea wireless communication technology transfers Seatooth SmartClamp data through the air/water boundary to a topside receiver.

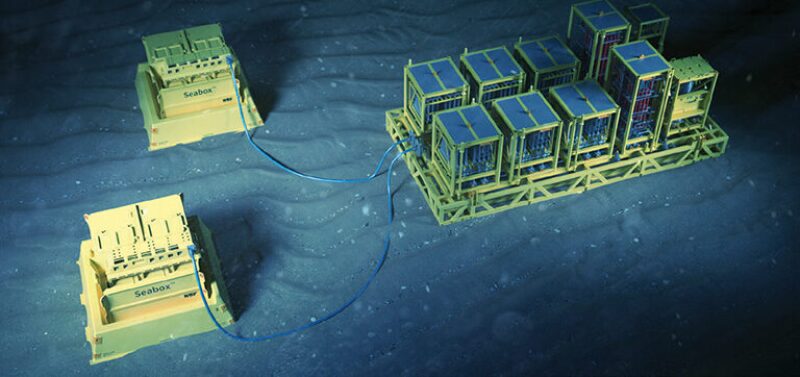

Subsea Cloud Computing Network Solution

The network’s architecture is enabled by integrating with a subsea control module to create a subsea Wi-Fi hotspot. Seatooth smart devices, with edge computing and low-power-management systems, are able to wirelessly connect directly to the network or cross-pollinate data using autonomous underwater vehicles or remotely operated vehicles for data gathering.

Upwing

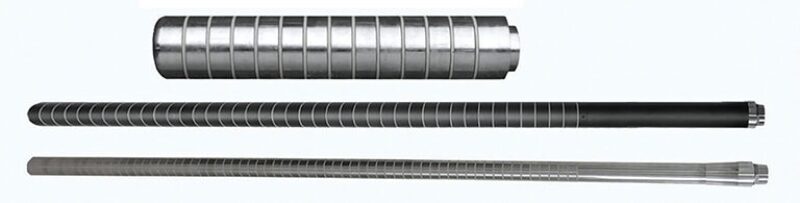

Subsurface Compression System

The Subsurface Compression System is the only high-speed downhole turbomachinery that increases gas production and recoverable reserves while removing liquid loading. It decreases the downhole flowing pressure, generating a higher drawdown that increases the inflow of gas from the gas reservoir and lowers the abandonment pressure, in turn increasing recoverable reserves.