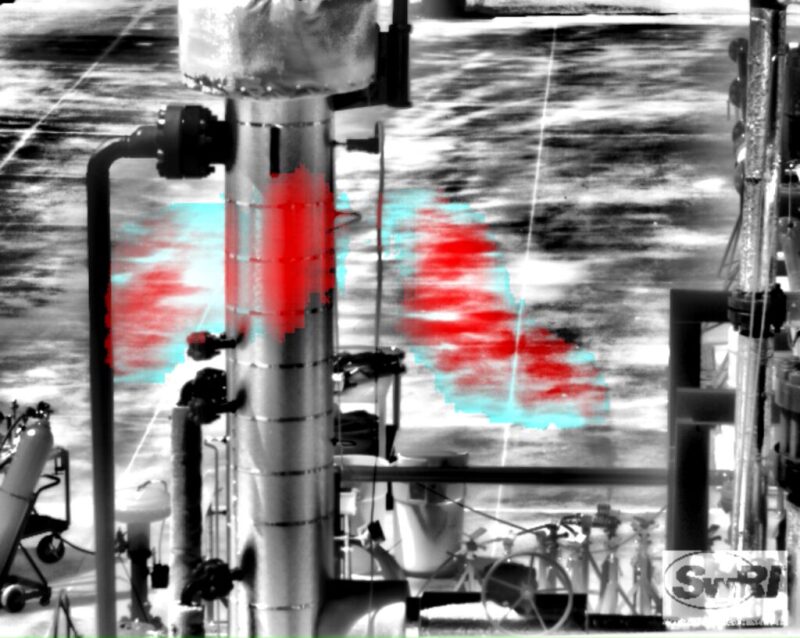

Southwest Research Institute (SwRI) is employing machine learning to measure fugitive methane emissions near valves, compressors, and pipelines where natural gas is gathered, transported, or distributed.

Methane is the primary component of natural gas and also a greenhouse gas; timely leak detection in remote areas is a significant need across the energy industry. Fusing computer vision and machine learning, SwRI’s solutions promise to detect and quantify natural gas flow.

Smart Methane Leak Detection, or SLED/M, is already proven to spot emissions that typically go unnoticed, and has been adapted for a number of applications; it can detect crude oil on water surfaces and find liquid hydrocarbon in pipelines and in facilities such as pump stations. In May 2019, the company launched a project to develop automated inspections of oil and gas facilities using SLED/M technology to detect methane leaks in real time, from aboard a drone.

SwRI is now advancing the science a step further, teaming computer scientists with sensing experts and fluids engineers to enhance SLED/M’s proven methane-detection algorithms with a physics model using 3D visuals to measure the volume of fugitive methane emissions and reduce false positives. The technology employs a longwave infrared thermal imager and a lightweight, light detection and ranging (LIDAR) system.

The project is particularly focused on developing new scalable quantification technologies, partly in response to a recent Stanford study that found only one in nine methane detection technologies are reliable.

SwRI said typically, natural gas leaks must be measured from several positions using a diode laser absorption spectroscopy instrument. These conventional methods are designed to locate larger leaks and are not only costly and time consuming but suffer from false positives and missed detections.

The SLED/M technology was funded by the DOE in 2016 and won an R&D 100 Award in 2017.