Completions

Malampaya East discovery is estimated to hold 98 Bcf of gas and may help offset declines at the country’s only producing gas field.

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

-

SponsoredTAQA's PulseEight Secure and SwellStack solutions avoid costly workovers and deferred production by riglessly retrofitting an alternative to failed subsurface safety valves.

-

This paper describes an optimized multizone single-trip gravel-pack system developed and implemented successfully in Brunei.

-

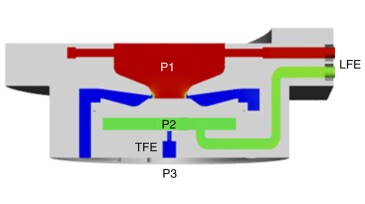

This paper describes the qualification of a multilayer, open-cell matrix polymer system for the first horizontal deployment in an offshore gas well.

-

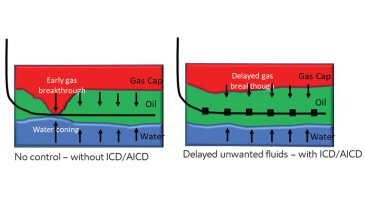

This paper describes installation of autonomous inflow control valves in the Bretaña Norte field in Peru, enabling effective water control even though the trial well was placed in the flank, close to the oil/water contact.

-

This paper provides insight into designing advanced well completions offshore West Africa with autonomous inflow control devices that enable maximizing the producing life of the wells under various challenging reservoir conditions.

-

The Energy & Environmental Research Center in North Dakota outlines the difficulty that the oil and gas industry faces in pinpointing sources of H2S production.

-

Drilling longer wells, increasing the number of fracture stages, and completing multiple zones in complex stacked reservoirs, along with optimizing multilateral wells with sand control to enable long laterals in stacked reservoirs, have emerged as key focuses of the industry.

-

These papers underscore the need for strategic adaptation of automation systems to the specific challenges of offshore environments. The success of predictive machine learning in this context depends on its ability to offer measurable financial benefits, improve safety, and drive operational efficiency.

-

One hydraulic fracturing job can stimulate two wells, but economic success hinges on doing it in the right place for the right price.

-

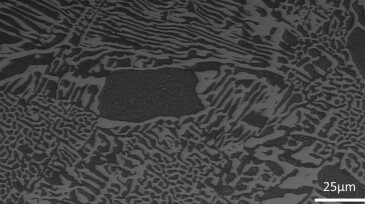

A comprehensive study looks at the sealing efficiency of eutectic bismuth-tin alloy plugs in wells slated for plugging and abandonment through laboratory testing, microscopy analyses, and numerical simulations.